7 Proven Strategies to Reduce Operational Costs in 2025

- Jun 28, 2025

- 13 min read

In today's competitive landscape, the conversation around cost-cutting has evolved. It is no longer about reactive, slash-and-burn tactics that can harm long-term growth. Instead, smart businesses are focusing on a proactive, systematic approach to reduce operational costs. This means embedding efficiency into the very DNA of your operations through intelligent automation and strategic optimization. A key aspect of this new era of cost reduction involves focusing on holistic strategies to improve operational efficiency. The goal is to build a leaner, more resilient organization that not only survives economic shifts but thrives by turning efficiency into a competitive advantage.

This article moves beyond generic advice and presents seven powerful, data-backed strategies that leverage technology and modern management principles. From integrating AI and workflow automation in tools like Zapier or Make.com to revolutionizing your supply chain, these methods offer a blueprint for sustainable cost savings and scalable growth. You will gain actionable insights into lean management, workforce optimization, and data-driven analytics. We will explore how automation-focused consultancies are helping businesses transform their processes, eliminating manual work to reclaim valuable time and resources. Prepare to discover practical, implementation-focused tactics to lower expenses while simultaneously boosting productivity and performance.

1. Implement Lean Management and Six Sigma Methodologies

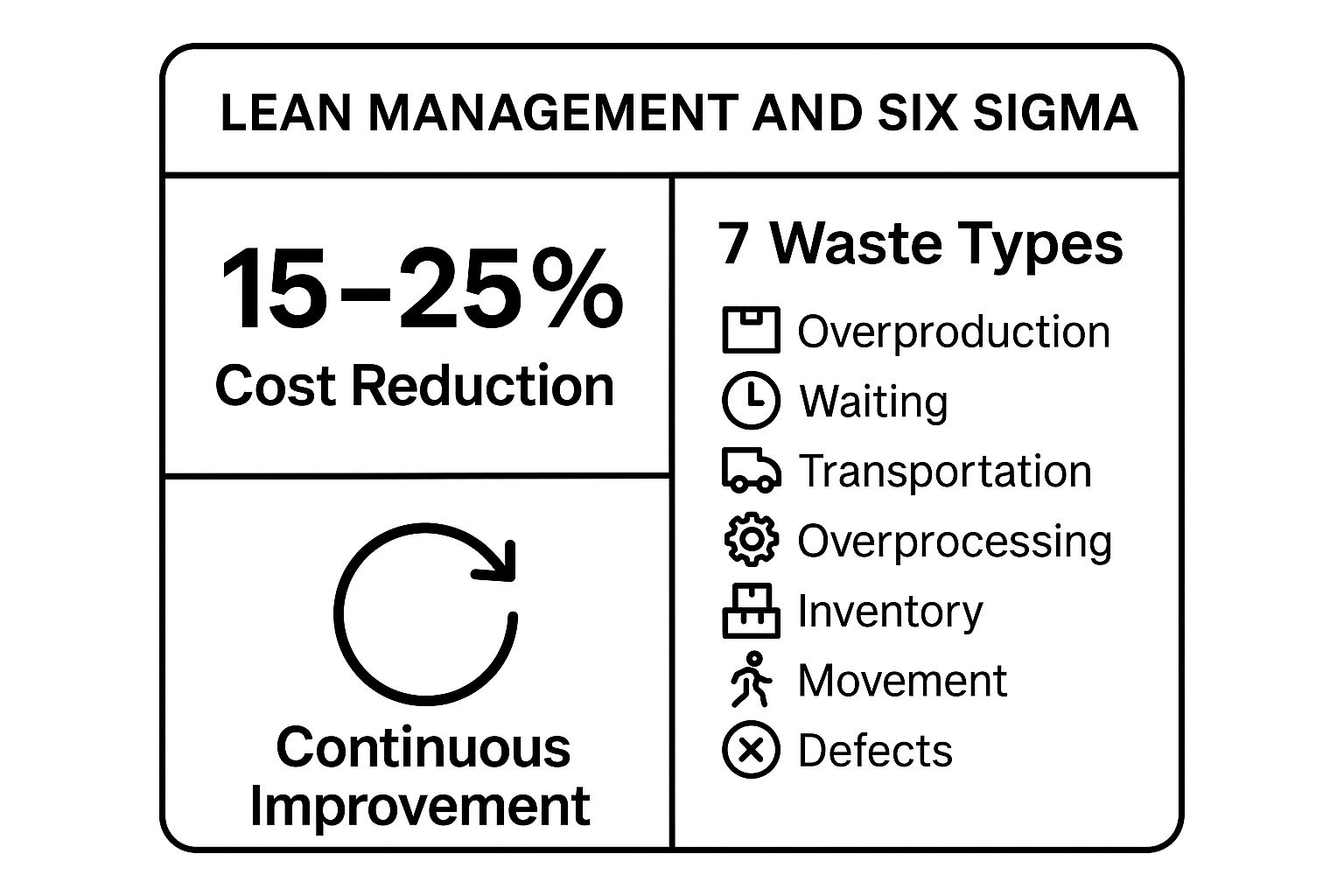

At its core, reducing operational costs is about eliminating waste and maximizing efficiency. Lean Management and Six Sigma are two powerful, complementary methodologies that provide a systematic framework for achieving precisely this. Lean focuses on maximizing customer value by relentlessly removing "waste" - any activity that consumes resources but adds no value. Six Sigma is a data-driven approach that uses statistical analysis to reduce defects and variations in any process, from manufacturing to customer service.

When combined, these methodologies create a culture of continuous improvement that systematically drives down expenses. For instance, Toyota’s famed Production System, a precursor to modern Lean, is credited with reducing its manufacturing costs by an estimated 30%. Similarly, General Electric famously saved over $12 billion in five years by integrating Six Sigma into its corporate DNA. These aren't just for industrial giants; the principles are scalable to any business aiming to streamline its operations.

How to Get Started

Implementing these systems requires a strategic, committed approach. It is not just about adopting a new tool but about shifting your organizational culture towards efficiency and quality.

Start with Pilot Projects: Identify a single, high-impact process with clear problems, like a slow customer onboarding workflow or a high-error invoicing system. Use this as a pilot project to demonstrate value and build momentum before a company-wide rollout.

Invest in Training: Your team is your greatest asset. Provide training and certification in Lean and Six Sigma principles (e.g., Green Belt, Black Belt) to equip them with the skills to identify and solve problems independently.

Measure Everything: You cannot improve what you do not measure. Establish and consistently track Key Performance Indicators (KPIs) related to the process you're improving, such as cycle time, defect rates, or cost per transaction.

The following infographic offers a quick reference on the core benefits and concepts of adopting a Lean Six Sigma approach.

As the data highlights, the goal is significant cost reduction driven by a relentless focus on eliminating the seven key wastes and embedding continuous improvement into your daily operations. This structured approach is a proven way to reduce operational costs by transforming how your business functions from the ground up.

2. Technology Automation and AI Integration

In today's digital landscape, one of the most powerful levers to reduce operational costs is the strategic implementation of automation and artificial intelligence. This involves using technologies like robotic process automation (RPA), machine learning, and smart systems to handle tasks traditionally performed by humans. The goal is to eliminate repetitive manual work, minimize human error, and unlock new levels of operational efficiency across the entire organization.

The impact of this approach is transformative. For example, JPMorgan Chase's COIN platform uses machine learning to analyze legal documents in seconds, a task that once took lawyers 360,000 hours annually. Similarly, UPS's route optimization system, ORION, leverages AI to save the company 100 million miles and millions of gallons of fuel each year. These examples demonstrate that automation isn't just about incremental improvements; it's about fundamentally re-engineering processes for maximum cost-effectiveness and performance.

How to Get Started

Integrating automation and AI requires a thoughtful, phased approach to ensure a positive return on investment and smooth adoption. It's about targeting the right processes and preparing your organization for a new way of working.

Start with High-Volume, Rule-Based Processes: Identify tasks that are repetitive, time-consuming, and follow clear rules. Think data entry, invoice processing, or generating standard reports. These are prime candidates for automation, offering quick wins and a clear demonstration of value.

Invest in Change Management: Automation changes roles, it doesn't just eliminate them. Invest in retraining and upskilling programs to transition employees from manual tasks to more strategic, value-added roles like process oversight, data analysis, or exception handling.

Conduct Thorough ROI Analysis: Before committing to a new technology, perform a detailed Return on Investment (ROI) analysis. Factor in software costs, implementation, training, and maintenance against projected savings from reduced labor hours, increased accuracy, and improved productivity.

By strategically applying technology, you can automate workflows and significantly cut down on operational overhead. This approach not only saves money but also frees up your team to focus on growth-driving initiatives. For a deeper dive into this topic, you can read more about a guide to business process automation on Flowgenius.ai.

3. Supply Chain Optimization

An inefficient supply chain is a major drain on operational budgets, leading to excess inventory, high transportation expenses, and costly delays. Supply chain optimization is a comprehensive strategy for streamlining every step of the process, from raw material procurement to final delivery. This approach focuses on creating a responsive, efficient, and cost-effective network by improving supplier relationships, refining inventory management, and leveraging data to make smarter logistical decisions.

The impact of a well-tuned supply chain is profound. Apple, under Tim Cook's operational leadership, perfected this by maintaining minimal inventory while ensuring product availability, a key factor in its high profitability. Similarly, Zara's agile supply chain allows it to move designs from concept to store in as little as 15 days, minimizing waste on unpopular items. These examples prove that a strategic supply chain is a powerful lever to reduce operational costs and gain a significant competitive edge.

How to Get Started

Optimizing your supply chain requires a holistic view of your entire value chain, from suppliers' suppliers to customers' customers. It involves a systematic effort to enhance visibility, collaboration, and efficiency across all nodes of the network.

Implement Supplier Scorecards: You cannot improve what you do not measure. Develop and regularly review supplier scorecards based on key metrics like on-time delivery, quality, and cost. This data-driven approach helps you identify top-performing partners and address issues with underperformers.

Leverage Demand Forecasting Analytics: Use historical sales data, market trends, and predictive analytics to forecast customer demand more accurately. This prevents costly overstocking (carrying costs) and understocking (lost sales), aligning your inventory directly with market needs.

Invest in Supply Chain Visibility Tools: Implement software that provides real-time visibility into your entire supply chain. Knowing where your inventory and shipments are at all times allows for proactive problem-solving and better decision-making. For businesses heavily reliant on logistics, understanding practical strategies to reduce costs in dealership car shipping and other transport-heavy sectors is crucial for efficiency.

By adopting these practices, you can transform your supply chain from a cost center into a strategic asset. If you are looking for more ways to enhance your network, you can learn more about proven methods to improve supply chain efficiency on flowgenius.ai.

4. Energy Efficiency and Sustainability Programs

Beyond immediate process fixes, a strategic focus on energy efficiency and sustainability offers a powerful, long-term approach to reduce operational costs. These programs involve systematically lowering energy consumption, adopting renewable energy sources, and embedding sustainable practices into your company culture. The goal is to cut utility expenses, one of the most significant operational overheads for many businesses, while simultaneously enhancing brand reputation and reducing environmental impact.

This isn't just an altruistic endeavor; it's a proven financial strategy. For instance, Google's commitment to operating on 100% renewable energy saves the company millions annually. Similarly, Interface Inc., under the guidance of its visionary founder Ray Anderson, achieved carbon neutrality and slashed its energy costs by 43% through its "Mission Zero" initiative. These examples demonstrate that sustainability and profitability are not mutually exclusive but are, in fact, deeply intertwined.

How to Get Started

Implementing a sustainability program is a strategic investment that pays dividends over time. It requires a thoughtful approach that combines technological upgrades with cultural engagement.

Conduct a Comprehensive Energy Audit: Before making any changes, you must understand your current consumption patterns. A professional energy audit will pinpoint specific areas of waste, from inefficient HVAC systems to outdated lighting, providing a clear roadmap for high-impact improvements. You can also explore options like implementing a building energy management system to get a detailed view of your consumption.

Leverage Rebates and Incentives: Governments and utility providers often offer substantial rebates, tax credits, and grants for businesses investing in energy-efficient technology. Researching and applying for these programs can significantly lower the upfront cost of upgrades like solar panels, LED lighting, or high-efficiency equipment.

Engage Your Team: Your employees can be your greatest allies in reducing waste. Create sustainability committees, run awareness campaigns, and incentivize energy-saving behaviors. Simple actions, like turning off lights and equipment when not in use, collectively lead to significant savings.

By prioritizing energy efficiency, you not only make a positive environmental impact but also create a more resilient and financially sound business. This proactive stance is a critical component for any organization looking to sustainably reduce operational costs for years to come.

5. Outsourcing and Offshoring Strategic Functions

Strategic outsourcing is more than just delegating tasks; it's the calculated transfer of specific business functions to external experts to leverage specialized skills, reduce labor costs, and sharpen focus on core competencies. This approach allows companies to convert fixed overheads, like salaries and infrastructure, into variable costs paid to a third-party provider. This is a powerful lever to reduce operational costs while simultaneously enhancing service quality and efficiency.

The impact can be transformative. Consider how American Express reportedly reduced its call center operating costs by 40% through strategic outsourcing. Similarly, IBM’s outsourcing services are known to help clients cut IT expenses by an average of 20-30%. These examples demonstrate that by partnering with specialists, whether for IT management, customer support, or manufacturing, businesses can access world-class capabilities without the significant internal investment, directly impacting their bottom line.

How to Get Started

A successful outsourcing strategy requires meticulous planning and strong relationship management. It is not a "set it and forget it" solution but a strategic partnership that needs active governance to yield long-term benefits.

Start with Non-Core Functions: Begin by outsourcing non-critical but resource-intensive processes, such as payroll processing, IT helpdesk support, or routine data entry. This allows you to test the provider relationship and internal processes with lower risk before considering more central functions.

Establish Clear Service Level Agreements (SLAs): Define your expectations in writing. Your SLA should include precise performance metrics, Key Performance Indicators (KPIs), reporting requirements, and penalties for non-compliance. This clarity prevents misunderstandings and ensures accountability.

Invest in Governance and Relationship Management: Do not abdicate responsibility. Appoint an internal manager to oversee the relationship, hold regular performance reviews, and maintain open communication channels. A strong partnership is essential for adapting to changing business needs and resolving issues effectively.

By carefully selecting partners and managing the relationship diligently, outsourcing becomes a formidable tool to reduce operational costs. It allows your business to become more agile, efficient, and focused on the activities that truly drive growth and competitive advantage.

6. Workforce Optimization and Flexible Staffing

Your workforce is often your largest operational expense, but it's also your most valuable asset. Workforce optimization isn't about cutting staff; it’s about strategically managing human resources to match labor costs with actual business needs. This involves embracing flexible staffing models like remote work, utilizing freelancers, and cross-training employees to create an agile, efficient, and highly productive team.

Adopting this approach can lead to dramatic savings. GitLab, a fully remote company, eliminates millions in real estate costs annually. Similarly, companies using platforms like Upwork for flexible talent can often see significant reductions in labor-related overhead. By rethinking the traditional 9-to-5, in-office structure, businesses can reduce operational costs while simultaneously accessing a broader, more diverse talent pool and increasing employee satisfaction.

How to Get Started

Implementing a flexible workforce strategy requires a shift in mindset from measuring presence to measuring performance. It demands trust, clear communication, and the right technological infrastructure to succeed.

Invest in Collaboration Technology: Equip your team with the right tools for seamless communication and project management, regardless of their location. Platforms like Slack, Asana, and Microsoft Teams are essential for keeping distributed teams aligned and productive.

Establish Clear Performance Metrics: When you can't see your team, you must measure their output. Define clear, results-oriented Key Performance Indicators (KPIs) for every role. This ensures accountability and focuses the team on what truly matters.

Implement Cross-Training Programs: Increase your team's versatility by training employees in multiple roles. This creates internal resilience, allowing you to adapt to workload fluctuations without immediately needing to hire new staff, effectively lowering labor costs and boosting efficiency.

By building a more flexible and skilled workforce, you create a resilient operational model that can adapt to changing market demands. This strategic approach to human resources is a powerful lever to reduce operational costs by optimizing your most significant investment: your people.

7. Data-Driven Cost Management and Analytics

In the modern business landscape, gut feelings are being replaced by granular data. Data-driven cost management is the systematic use of advanced analytics, business intelligence, and data science to pinpoint cost-saving opportunities, optimize resource allocation, and inform every financial decision. This approach transforms raw data into a strategic asset, using predictive analytics and real-time monitoring to continuously find and eliminate financial inefficiencies across the entire organization.

This method moves beyond simple expense tracking to predictive and prescriptive insights. For example, UPS’s famous ORION (On-Road Integrated Optimization and Navigation) system uses advanced algorithms to analyze fleet data, saving an estimated $400 million annually in fuel and time. Similarly, Netflix leverages immense viewership data not just to recommend shows but to make billion-dollar content acquisition and production decisions, minimizing the risk of costly flops. These industry leaders prove that a commitment to analytics is essential to reduce operational costs at scale.

How to Get Started

Embracing data-driven management is a cultural shift that requires the right tools, talent, and processes. It’s about empowering your teams to ask the right questions and giving them the data to find the answers.

Establish a Clean Data Foundation: Your insights are only as good as your data. Start by centralizing and cleaning your data sources, whether they are from your CRM, ERP, or operational software. Ensure data is accurate, consistent, and accessible.

Focus on Actionable Insights: Avoid "analysis paralysis" by creating dashboards and reports that highlight actionable insights, not just vanity metrics. For instance, instead of just reporting total marketing spend, track cost-per-acquisition by channel to see where your budget is truly effective.

Implement Automated Anomaly Alerts: Use analytics tools to set up automated alerts for significant cost deviations or budget overruns. This proactive monitoring allows you to address financial issues in real time, long before they appear on a monthly report.

Invest in Analytics Talent: You need people who can interpret data and tell a story with it. Invest in training your existing team or hire analysts who are skilled in turning complex datasets into clear, strategic recommendations for cost optimization.

Cost Reduction Strategies Comparison

Item | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Lean Management and Six Sigma | High – requires extensive training and cultural change | Substantial upfront training and ongoing employee engagement | Significant cost reduction (15-25%), improved quality, faster delivery | Process-heavy industries aiming to reduce waste and defects | Strong focus on continuous improvement and employee empowerment |

Technology Automation and AI Integration | Very High – needs specialized technical expertise and ongoing maintenance | High initial costs, advanced IT infrastructure | Labor cost reduction, 24/7 operations, enhanced accuracy | Repetitive, rule-based tasks with large volumes | Scalability, accuracy, and operational efficiency |

Supply Chain Optimization | Moderate to high – depends on scale and system integration | Investment in forecasting tools and supplier management | Reduced inventory costs (20-30%), improved cash flow, fewer stockouts | Manufacturing and retail businesses with complex supply chains | Enhanced supply chain visibility and supplier relationships |

Energy Efficiency and Sustainability Programs | Moderate – involves capital investment and technology upgrades | High upfront capital with potential subsidies | Long-term utility cost savings (20-40%), improved brand reputation | Energy-intensive operations seeking sustainability goals | Regulatory incentives and long-term cost savings |

Outsourcing and Offshoring Strategic Functions | Moderate – requires vendor selection and contract management | Lower capital costs but requires governance resources | Significant labor cost savings (30-60%), access to expertise | Non-core business functions and scalable operations | Cost savings and operational flexibility |

Workforce Optimization and Flexible Staffing | Moderate – requires HR strategy changes and new management practices | Investment in collaboration tools and training | Reduced overhead, increased agility, higher retention | Organizations adopting remote or flexible work models | Workforce scalability and improved employee satisfaction |

Data-Driven Cost Management and Analytics | High – complex integration of data systems and analytics expertise | Significant investment in technology and skilled personnel | Precise cost control, improved forecasting, continuous optimization | Businesses focused on financial efficiency and resource allocation | Data-driven decisions and real-time cost visibility |

Automate Your Way to a More Profitable Future

The journey to systematically reduce operational costs is not a one-time project but a fundamental shift in organizational culture. It’s about building a resilient, agile, and intelligent operational framework. The seven strategies explored throughout this article, from Lean Management and Six Sigma to strategic outsourcing and data-driven analytics, are not isolated tactics. Instead, they are interconnected pillars that support a common goal: maximizing value while minimizing waste.

The true power of these approaches is unlocked when they are unified by a central theme: intelligent automation. By weaving automation into the fabric of your operations, you move beyond simple cost-cutting and into the realm of strategic optimization. This creates a powerful cycle of continuous improvement where efficiency gains in one area, like your supply chain, amplify savings in another, such as workforce management.

From Theory to Action: Your Next Steps

The most critical takeaway is that sustainable cost reduction is proactive, not reactive. It begins with a commitment to identifying and eliminating inefficiencies before they escalate. Instead of waiting for budget crises, successful leaders build systems that are inherently lean and efficient. This involves a cultural shift where every team member is empowered to question processes and seek better, more automated solutions.

Here are actionable next steps to turn these insights into tangible results:

Conduct an Automation Audit: Start small. Identify the top three most time-consuming, repetitive, and manual tasks within your organization. This could be anything from data entry and report generation to outbound calling or CRM updates.

Implement a Pilot Project: Choose one process from your audit and automate it using tools like Zapier, Make.com, or a custom solution. For instance, transitioning to digital systems like paperless work orders is a prime example of how automation can drastically reduce operational expenses and save countless hours. Measure the impact on time, cost, and employee satisfaction.

Empower Your Team: Provide your staff with the training and tools needed to embrace an automation-first mindset. Encourage them to use platforms like GoHighLevel or n8n to streamline their own workflows, fostering a bottom-up approach to innovation.

Ultimately, the goal is to create an operational ecosystem where automation handles the mundane, freeing your human talent to focus on what they do best: strategy, creativity, and building customer relationships. By embracing these principles, you are not just trimming expenses; you are investing in a more scalable, profitable, and resilient future for your organization. This strategic approach ensures that you can reduce operational costs not just for the next quarter, but for years to come.

Ready to transform your operational workflows from a cost center into a competitive advantage? The experts at Flow Genius specialize in designing and implementing custom automation blueprints that drive efficiency and profitability. Visit Flow Genius to schedule a free consultation and discover your automation potential.

Comments