9 Proven Strategies to Reduce Operating Costs in 2025

- Matthew Amann

- Jul 23, 2025

- 14 min read

In today's competitive landscape, the ability to effectively reduce operating costs is no longer just a financial exercise; it is a critical strategic advantage. While traditional methods like budget cuts and hiring freezes offer temporary relief, sustainable success requires a deeper, more intelligent approach. This means moving beyond simple belt-tightening and embracing transformative strategies that enhance efficiency, eliminate waste, and build a more resilient organization from the ground up.

This article provides a new playbook for achieving significant cost reductions, focusing on nine powerful, industry-tested methodologies. We will move past generic advice to deliver practical, actionable frameworks you can implement immediately. From adopting Lean Six Sigma principles and implementing process automation to leveraging strategic outsourcing and Zero-Based Budgeting, each point offers a unique pathway.

The goal is to equip you with the tools to not only slash expenses but also to unlock new levels of productivity and innovation. By focusing on these specific, high-impact areas, you can set your business on a course for long-term growth and stability, transforming cost management from a defensive reaction into a proactive strategy for securing a competitive edge.

1. Lean Manufacturing/Six Sigma

Pioneered by industry giants like Toyota and Motorola, Lean Six Sigma is a powerful, data-driven methodology for systematically removing waste and reducing defects from any business process. This dual approach helps you reduce operating costs by tackling inefficiencies head-on. Lean focuses on eliminating non-value-added activities, while Six Sigma aims to minimize process variation and errors, leading to higher quality and consistency.

For example, General Electric famously saved over $12 billion in five years by implementing Six Sigma. Similarly, Amazon uses Lean principles in its fulfillment centers to cut order processing times significantly, directly lowering operational expenses per package.

How to Implement Lean Six Sigma

Getting started doesn't require a complete organizational overhaul. Begin by identifying a high-impact, low-complexity area for a pilot project.

Invest in Training: Equip your team with the necessary skills. Certifications in Lean Six Sigma are invaluable for leading improvement projects.

Establish Clear Metrics: Define what success looks like. Key Performance Indicators (KPIs) like defect rate, cycle time, and customer satisfaction are crucial.

Visualize Progress: Use data visualization tools and dashboards to track improvements and maintain momentum.

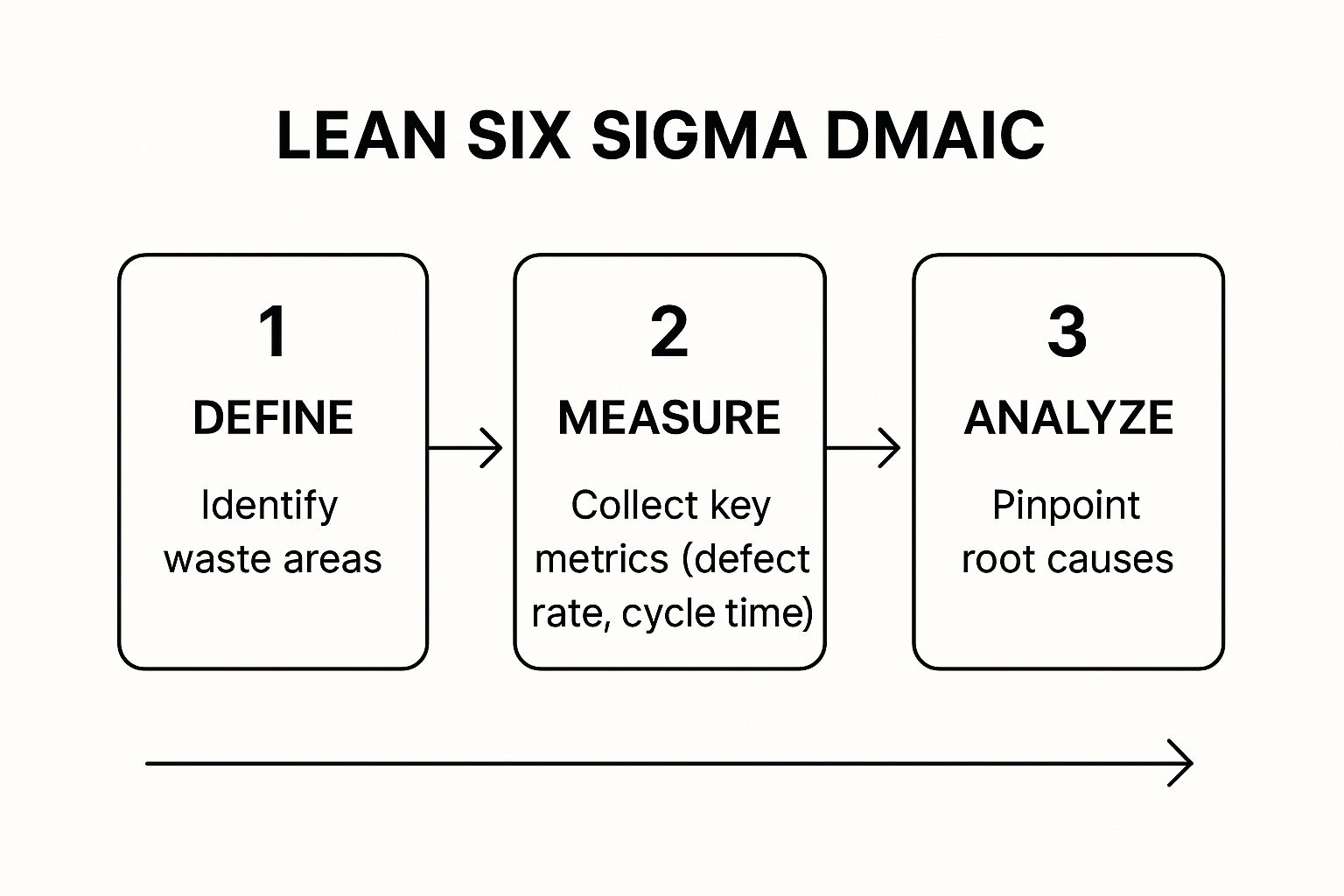

To kickstart the process, many organizations use the DMAIC (Define, Measure, Analyze, Improve, Control) framework. This structured approach provides a clear roadmap for identifying and solving problems.

The infographic below illustrates the initial, critical steps of the DMAIC cycle.

Following this flow ensures that improvement efforts are based on concrete data rather than assumptions, leading to more effective and sustainable cost reductions. As one of the most effective process improvement techniques, Lean Six Sigma offers a proven path to operational excellence. You can learn more about key process improvement techniques here.

2. Process Automation and Digital Transformation

Process automation involves using technology to execute repetitive, rule-based tasks that were previously performed by humans. This digital transformation streamlines workflows, reduces manual errors, and frees up employees to focus on higher-value activities. By implementing tools like Robotic Process Automation (RPA) and AI, businesses can significantly reduce operating costs associated with labor, time, and resource management.

For instance, JPMorgan Chase’s COIN program reviews complex legal documents in seconds, a task that once took 360,000 human work hours annually. Similarly, global insurer Generali Group partnered with UiPath to automate 1.5 million transactions per year, drastically improving efficiency. These examples show how targeted automation directly cuts operational overhead and accelerates business processes.

How to Implement Process Automation

Integrating automation is a strategic initiative that should start with clear goals and a phased approach. Focus first on high-volume, low-complexity tasks for quick wins and measurable ROI.

Identify Automation Opportunities: Start by mapping your existing workflows to find bottlenecks and repetitive tasks. Areas like data entry, invoice processing, and report generation are excellent candidates.

Conduct a Cost-Benefit Analysis: Before investing, analyze the potential savings in labor costs and efficiency gains against the cost of software, implementation, and maintenance.

Prioritize Change Management: Prepare your team for the transition. Effective change management includes clear communication and retraining programs to help employees adapt to new, more strategic roles.

Choose Scalable Platforms: Select automation tools like those from Automation Anywhere or Microsoft's Power Platform that can grow with your business and integrate with your existing systems.

A great starting point is to apply automation to rule-based processes where human decision-making is minimal. This ensures a smoother implementation and provides a solid foundation for more complex AI-driven projects later. You can explore a variety of automation solutions and workflows here.

3. Strategic Outsourcing and Offshoring

Popularized by thought leaders like Michael Corbett and implemented by pioneers such as Accenture, strategic outsourcing is the practice of contracting specific business functions to external providers. This approach allows companies to reduce operating costs by leveraging specialized expertise and economies of scale, freeing up internal resources to focus on core competencies. The key is to move non-critical tasks to partners who can perform them more efficiently and cost-effectively.

For example, Procter & Gamble saved a reported $2.8 billion over a decade by outsourcing its HR functions. Similarly, the lean messaging app WhatsApp was able to operate with only 55 employees at the time of its acquisition by outsourcing most non-core functions, showcasing the immense power of this strategy to enable rapid growth with minimal overhead.

How to Implement Strategic Outsourcing

Successful outsourcing goes beyond simply finding the cheapest provider. It requires a clear strategy and robust management to ensure quality and alignment with your business goals.

Define Scope and Metrics: Clearly document the tasks to be outsourced, service level agreements (SLAs), and Key Performance Indicators (KPIs) to measure performance.

Choose Proven Providers: Select partners with a strong track record in your required area. When exploring options, it's essential to identify the best countries for outsourcing to find a location that aligns with your needs for talent, cost, and time zone.

Maintain Strong Governance: Establish clear communication channels and regular review meetings to manage the relationship and address issues proactively.

To mitigate risk, many businesses begin with a pilot project for a non-critical function. This allows you to test the provider's capabilities and refine your processes before committing to a larger-scale engagement, ensuring a smoother transition and more predictable cost savings.

4. Energy Efficiency and Sustainability Initiatives

championed by pioneers like Ray Anderson of Interface Inc., energy efficiency and sustainability initiatives offer a powerful way to reduce operating costs while simultaneously enhancing corporate responsibility. This approach involves systematically cutting energy consumption, optimizing resource usage, and adopting sustainable practices that deliver direct financial benefits. It moves beyond simple conservation to strategically invest in technologies and processes that lower utility bills and reduce environmental impact for the long term.

The financial returns can be immense. For instance, Walmart saved an estimated $1 billion annually through comprehensive energy efficiency programs, while Google’s commitment to carbon neutrality led to over $1 billion in savings through renewable energy and efficiency. Similarly, 3M's renowned "Pollution Prevention Pays" program has saved the company over $2.2 billion since 1975 by reducing waste and improving operational eco-efficiency.

How to Implement Energy and Sustainability Programs

Starting an effective program requires a data-driven approach rather than guesswork. Focus on identifying the largest areas of consumption first to maximize your return on investment.

Conduct an Energy Audit: Begin with a comprehensive energy audit to identify where your facility consumes the most power. This provides a baseline for measuring improvements.

Prioritize High-Impact Upgrades: Focus on low-cost, high-impact changes first, such as switching to LED lighting or installing programmable thermostats. Then, plan for larger investments like upgrading HVAC systems or improving insulation.

Leverage Financial Incentives: Take full advantage of available utility rebates, tax credits, and government grants designed to encourage energy-efficient upgrades.

Engage Your Team: Foster a culture of conservation by involving employees. Simple initiatives like turning off lights and equipment can lead to significant cumulative savings.

Setting clear, measurable sustainability goals and tracking progress with dedicated tools is key to maintaining momentum. This structured approach ensures that your efforts translate directly into lower operational expenses. You can learn more about managing facility energy use effectively here.

5. Supply Chain Optimization

Spearheaded by innovators like Apple's Tim Cook and Dell's Michael Dell, supply chain optimization involves strategically redesigning and managing supply networks to slash expenses while upholding service quality. This discipline helps you reduce operating costs by streamlining everything from procurement and inventory to logistics. It focuses on creating a lean, responsive, and cost-effective system from raw materials to the final customer delivery.

For example, Dell’s pioneering direct-to-consumer model eliminated intermediary distributor and retailer costs, fundamentally changing the PC industry. Likewise, Zara’s agile "fast fashion" supply chain allows it to minimize inventory holding costs and respond rapidly to market trends, a key competitive advantage.

How to Implement Supply Chain Optimization

Optimizing your supply chain doesn't mean starting from scratch. It starts with a comprehensive analysis to pinpoint inefficiencies and opportunities for improvement.

Map Your Supply Chain: Create a detailed visual map of your entire supply chain, from suppliers' suppliers to end customers, to identify bottlenecks and redundant processes.

Implement Supplier Scorecards: Develop and track performance metrics for your vendors based on cost, quality, and delivery reliability to foster accountability and continuous improvement.

Leverage Predictive Analytics: Use data and forecasting tools for more accurate demand planning, which helps prevent costly overstocking or stockouts.

Negotiate Strategically: Pursue long-term contracts with key suppliers to secure volume discounts and build stronger, more collaborative partnerships.

To truly excel, businesses must embrace data-driven decision-making. Mapping the process and setting clear KPIs provide the foundation for making informed changes that lead to sustainable savings. You can learn more about the best supply chain analytics tools here.

6. Shared Services and Centralization

Championed by leaders like Jack Welch at General Electric, shared services involves consolidating common business functions from multiple departments into a single, centralized unit. This strategy directly attacks redundant efforts and creates economies of scale, helping you reduce operating costs across the board. Instead of each department having its own HR, finance, or IT support, a central team handles these tasks, standardizing processes and improving efficiency.

For example, Procter & Gamble consolidated its global finance and accounting operations, saving an estimated $300 million annually. Likewise, Johnson & Johnson's Global Services model reportedly reduced costs by over 25% by centralizing functions like procurement and IT, while Ford Motor Company’s shared services center now processes more than one million transactions per month, showcasing massive operational scale.

How to Implement Shared Services

Implementing a shared services model requires careful planning and a phased approach to ensure a smooth transition without disrupting business operations.

Start with Standardized Processes: Begin with high-volume, transactional functions that are easy to standardize, such as accounts payable or payroll.

Establish Clear Governance: Define roles, responsibilities, and performance expectations with Service Level Agreements (SLAs). This ensures the central unit is accountable to the business units it serves.

Invest in Enabling Technology: Use technology platforms like Enterprise Resource Planning (ERP) systems or dedicated service management software to automate workflows and provide a seamless user experience.

To ensure success, maintain strong and continuous communication with all business stakeholders. Regularly reporting on key metrics like service quality and cost savings will demonstrate value and build trust in the new model. You can find more insights on this model from advisory firms like Deloitte, which specialize in helping organizations transition to centralized operations.

7. Cloud Migration and IT Infrastructure Optimization

Pioneered by cloud giants like Amazon Web Services (AWS) and Microsoft Azure, this strategy involves moving your IT systems from costly on-premises servers to scalable cloud platforms. This shift directly helps you reduce operating costs by converting large capital expenditures into predictable operational expenses. By optimizing your infrastructure in the cloud, you eliminate the need for physical hardware maintenance, lower energy consumption, and gain access to powerful, on-demand computing resources.

For instance, Netflix famously migrated its entire infrastructure to AWS, gaining immense scalability and saving millions in data center costs. Similarly, General Electric reduced its IT operational budget by 52% through strategic cloud adoption, and Capital One shuttered eight of its physical data centers after moving its operations to the cloud, showcasing a massive reduction in fixed overheads.

How to Implement Cloud Migration and Optimization

A successful migration requires careful planning and a phased approach. It's not just about lifting and shifting; it's about re-architecting for efficiency.

Conduct a Thorough Analysis: Before migrating, perform a detailed cost-benefit analysis. Account for direct costs like subscriptions and potential hidden costs like data transfer fees or specialized support.

Start with a Pilot Project: Begin by moving non-critical applications to the cloud. This allows your team to gain experience and iron out any issues in a low-risk environment before tackling core systems.

Implement Cloud Governance: Use cloud cost management and monitoring tools from the start. Set budgets, alerts, and access controls to prevent unexpected spending and ensure security.

To ensure long-term success, focus on choosing the right cloud provider and services that align with your specific business needs. Investing in training your IT staff on new cloud technologies is also crucial for maximizing your return on investment and maintaining a secure, optimized environment. This strategic move from physical to virtual infrastructure is a proven method for achieving significant and sustainable cost savings.

8. Workforce Optimization and Flexible Staffing

Workforce optimization involves strategically aligning your human resources with fluctuating business demands to maximize productivity and minimize labor-related expenses. This approach goes beyond simple scheduling; it encompasses flexible work arrangements, cross-training, and alternative staffing models to reduce operating costs without sacrificing output or quality. By creating an agile workforce, you can scale operations up or down efficiently, ensuring you have the right talent at the right time.

Pioneers in this space have demonstrated its significant impact. Automattic, the company behind WordPress.com, operates a fully remote model, achieving immense cost savings on real estate and overhead. Similarly, Microsoft Japan experimented with a four-day work week and saw productivity jump by 40%. These examples show that flexible staffing isn't just about cutting hours; it's about re-engineering the work model for better results and lower costs.

How to Implement Workforce Optimization

Adopting a flexible model requires a foundation of clear policies and robust communication. Start by identifying roles or departments where demand varies or remote work is feasible.

Establish Clear Policies: Create detailed guidelines for remote work, flexible hours, and performance expectations. Use performance metrics, not hours logged, to measure productivity.

Invest in Collaboration Tools: Equip your team with the right technology (like Slack, Asana, or Microsoft Teams) to ensure seamless communication and project management, regardless of location.

Use Workforce Analytics: Leverage data to forecast demand and identify optimization opportunities. Analytics can reveal patterns in workload, helping you make informed staffing decisions.

Develop a Contingent Worker Program: Build a reliable network of freelancers, contractors, or part-time staff through platforms like Upwork to handle periodic spikes in work without adding permanent overhead.

This strategy is ideal for businesses with seasonal or project-based workloads. By moving away from a rigid, traditional staffing structure, you can build a more resilient and cost-effective organization prepared to adapt to market changes. You can learn more about building a successful remote team from leaders like GitLab.

9. Zero-Based Budgeting (ZBB)

Pioneered by Peter Pyhrr and famously executed by firms like 3G Capital, Zero-Based Budgeting (ZBB) is a radical departure from traditional budgeting. Instead of adjusting the previous year's budget, ZBB requires every department to justify all expenses from scratch, forcing a critical evaluation of every dollar spent. This approach helps reduce operating costs by eliminating legacy inefficiencies and aligning spending with current strategic priorities.

For instance, 3G Capital's acquisition of Heinz saw a $1.5 billion cost reduction through ZBB implementation. Similarly, Unilever achieved over €2 billion in savings, and Mondelez International cut its cost base by $3 billion over three years by adopting this rigorous methodology. These examples highlight ZBB's power to drive significant financial discipline.

How to Implement Zero-Based Budgeting

Adopting ZBB requires a cultural shift towards accountability and data-driven decision-making. Starting with a targeted pilot can smooth the transition for the wider organization.

Provide Extensive Training: Ensure all managers and department heads understand the ZBB philosophy and the justification process. Clear communication is essential to prevent fear and encourage buy-in.

Leverage Technology: Use budgeting and analytics software to streamline the process of building, justifying, and tracking budgets from the ground up. This reduces the administrative burden.

Balance Cuts with Investment: ZBB is not just about cutting costs. It's about reallocating resources to high-growth areas. Ensure the process protects and prioritizes strategic investments.

To begin, identify a few pilot departments to test the methodology. This allows you to refine your approach before a company-wide rollout. By compelling leaders to scrutinize every expense, ZBB ensures that all spending is purposeful, efficient, and directly contributes to organizational goals, making it a powerful tool to reduce operating costs sustainably.

Operating Cost Reduction Strategies Comparison

Approach | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Lean Manufacturing / Six Sigma | High – requires training, cultural change | Significant upfront training and leadership commitment | 15-25% cost reduction, quality improvement, sustainable savings | Manufacturing, process improvement, quality control | Waste elimination, defect reduction, continuous improvement |

Process Automation & Digital Transformation | High – technical setup, maintenance | High initial costs, technical expertise needed | 20-50% labor cost reduction, faster processing, 24/7 operations | Repetitive tasks, data-driven workflows | Accuracy improvement, speed, scalable automation |

Strategic Outsourcing & Offshoring | Medium to High – contract and vendor management | Moderate to high depending on scope and location | 20-70% cost reduction, access to expertise, faster delivery | Non-core business functions, cost reduction | Cost arbitrage, specialized skills, flexibility |

Energy Efficiency & Sustainability Initiatives | Medium – technical upgrades, audits | High initial capital investment | 10-30% utility cost savings, tax incentives, brand enhancement | Facilities management, environmental goals | Long-term savings, ESG improvement, regulatory benefits |

Supply Chain Optimization | High – cross-functional coordination | Significant data integration and analytics tools | 10-20% cost reduction, improved supplier relations, enhanced resilience | Inventory, logistics, supplier management | Cost savings, supply chain visibility, risk management |

Shared Services and Centralization | Medium to High – organizational restructuring | Investment in technology and governance | 15-40% operational cost reduction, process standardization | Back-office functions, multi-unit organizations | Economies of scale, improved service quality |

Cloud Migration & IT Infrastructure Optimization | High – complex migration and training | Initial migration cost, ongoing subscription fees | 20-50% IT cost reduction, improved scalability, faster deployment | IT systems, scalability needs | Flexibility, reduced hardware maintenance, advanced tech |

Workforce Optimization & Flexible Staffing | Medium – requires policy and culture changes | Investment in training and collaboration tools | 10-25% labor cost reduction, increased flexibility and retention | HR management, fluctuating demand | Workforce agility, employee satisfaction, cost control |

Zero-Based Budgeting (ZBB) | High – thorough review and justification process | Time and resource intensive | 10-25% cost reduction, cost transparency, aligned spending | Budgeting, cost control | Eliminates waste, enforces accountability |

From Strategy to Action: Building Your Cost-Efficient Future

The journey to reduce operating costs is not a destination but a continuous, dynamic process. Throughout this guide, we've explored nine powerful strategies, moving from foundational principles like Lean Six Sigma and Zero-Based Budgeting to transformative technological shifts like process automation and cloud migration. Each method offers a unique lens through which to view your organization, identify inefficiencies, and unlock hidden value. The true power, however, doesn't lie in adopting a single strategy but in thoughtfully integrating a tailored combination that aligns with your specific industry, operational scale, and long-term goals.

For a commercial cleaning business, the first step might be automating scheduling and supply replenishment. For a technology company, it could be integrating disparate software systems through a platform like Zapier or Make to eliminate manual data entry. The common thread is the commitment to proactive, strategic change rather than reactive, last-minute cuts.

Key Takeaways for Sustainable Cost Reduction

The most impactful takeaway is that modern cost management is fundamentally about working smarter, not just leaner. It's about empowering your teams with better processes and more intelligent tools. This proactive approach ensures that efforts to reduce operating costs don't inadvertently stifle innovation or compromise quality.

Consider these core principles as you move forward:

Integration is Key: The greatest efficiencies are often found at the intersection of different strategies. For example, a Supply Chain Optimization initiative (Strategy #5) becomes exponentially more powerful when supported by Process Automation (Strategy #2) and Cloud Infrastructure (Strategy #7).

Data Drives Decisions: Whether implementing Zero-Based Budgeting or optimizing your workforce, success hinges on accurate, real-time data. Gut feelings are no substitute for a clear, analytical understanding of your expenses and performance metrics.

Start Small, Scale Smart: The idea of a complete digital transformation can be paralyzing. Instead, identify one high-impact, low-risk area for improvement. Automating a single, repetitive CRM workflow or optimizing one energy-intensive process can build momentum and provide a clear business case for broader initiatives.

Your Action Plan for a More Efficient Future

Mastering these concepts is no longer just about protecting profit margins; it's about building a resilient, agile, and competitive organization. By systematically reducing operational waste, you free up critical capital and human resources that can be reinvested into areas that truly drive growth: product development, customer experience, and market expansion. An efficient operation is a strategic asset.

Don't let the complexity of implementation hold you back. The path to a leaner, more automated business begins with a single, decisive step. Analyze the strategies we've discussed, identify the one that resonates most with your current challenges, and commit to exploring its potential. The sustainable, cost-efficient future you envision is built one optimized process at a time.

Ready to turn these strategies into reality but unsure where to start? The team at Flow Genius specializes in dissecting complex business workflows and building powerful automation solutions that directly reduce operating costs. Visit Flow Genius to book a discovery call and map out your custom automation blueprint today.