A Guide to Process Improvement Methodology

- Matthew Amann

- Jul 25, 2025

- 16 min read

When someone talks about a "process improvement methodology," what they're really talking about is a structured way to make your business run better. It’s the difference between randomly fixing problems as they pop up and having a reliable game plan to systematically find and eliminate inefficiencies for good.

This is the strategic toolkit that shifts your operations from constant firefighting to proactive, intelligent improvement.

Understanding the Foundation of Process Improvement

Think of a process improvement methodology as a master mechanic’s diagnostic toolkit for a high-performance engine. You wouldn't just start tinkering with parts and hope for the best, right? A good mechanic uses specific tools and a proven process to identify the root cause of an issue and implement a lasting fix. That's precisely what these methodologies do for your business.

They transform vague goals like “we need to be more efficient” into concrete, measurable steps that produce real results. The aim isn't just about working harder; it's about working smarter. By building a culture where everyone is always looking for ways to improve, you can deliver more value to your customers, cut down on internal friction, and ultimately strengthen your bottom line. You're building systems that work well now and are nimble enough to adapt to whatever comes next.

Why Structure Matters More Than Ever

Let's be honest: without a formal methodology, most "improvement" efforts are doomed to fail. They tend to be disorganized, lack clear goals, and fizzle out as soon as the initial excitement wears off. A structured framework provides the guardrails needed for success. It ensures every initiative is guided by data, focused on what truly matters, and tied directly to the company's strategic objectives.

The proof is in the numbers. Organizations that commit to a dedicated approach to process improvement see real, tangible benefits.

A focus on continuous process improvement typically leads to a 20% increase in operational efficiency within the first year. Over time, these companies can achieve a 40% reduction in defects and a 30% decrease in operational costs.

This kind of structure brings a few critical advantages to the table:

Clarity and Focus: It forces teams to define exactly what problem they're trying to solve and why it's important, which stops people from wasting time on low-impact activities.

Consistency: When everyone uses the same methods and speaks the same language, different departments can actually collaborate effectively on improvements.

Accountability: With defined steps, clear roles, and specific metrics, tracking progress and holding teams accountable for results becomes straightforward.

Ultimately, adopting a process improvement methodology is about building a more resilient and efficient organization. It’s the difference between frantically patching holes in a leaky boat and engineering a ship designed to weather any storm. When you embed these principles into your daily operations, you're not just making small tweaks—you're building a powerful engine for sustained growth and a serious competitive edge.

The Three Pillars of Process Improvement

When you start digging into process improvement, you'll hear three names pop up again and again: Lean, Six Sigma, and Kaizen. While they’re often mentioned in the same breath, they are actually distinct disciplines with their own unique philosophies and strengths. Getting a handle on these three pillars is the first real step toward picking the right approach for whatever challenge your business is facing.

Let’s unpack them one by one, using some simple analogies to make the core ideas really click.

Lean: The Quest for Maximum Value with Minimum Waste

Picture a high-end restaurant kitchen during the Saturday night dinner rush. Every single movement has a purpose. Ingredients are prepped and waiting exactly where they're needed, the chefs move with a practiced, almost balletic efficiency, and there are absolutely no wasted steps. The goal is simple: get a flawless meal to the customer as quickly as humanly possible.

That, in a nutshell, is the essence of Lean.

At its heart, the Lean methodology is obsessed with one thing: eliminating waste to maximize the value delivered to the customer. And "waste" here isn't just about throwing away leftover food. It’s anything that doesn't add value to the final product from the customer's point of view.

Lean pinpoints eight specific types of waste, often remembered with the handy acronym DOWNTIME:

Defects: Products or services that need to be fixed or tossed out.

Overproduction: Making more than you need right now, which leads to storage costs.

Waiting: Idle time between steps, like waiting for an approval or for another task to finish.

Non-Utilized Talent: Not tapping into the skills, knowledge, and creativity of your team.

Transportation: Needless movement of products, materials, or even information.

Inventory: Excess materials or finished goods that just sit there, tying up cash and space.

Motion: Pointless movement of people, like walking across the office to a printer.

Extra-Processing: Doing more work than the customer actually needs, like adding features nobody asked for.

By methodically hunting down and getting rid of these wastes, a business becomes faster, more agile, and far more cost-effective. Lean is all about improving flow and speed. It’s the perfect fit for businesses aiming to slash delivery times, cut operational costs, and react faster to customer demands.

Six Sigma: The Scientific Pursuit of Perfection

Now, let's switch gears. Forget the kitchen and imagine a sterile, high-tech laboratory where scientists are developing a life-saving drug. In this environment, every measurement has to be exact. Every variable must be tightly controlled. Every outcome has to be perfectly repeatable. Why? Because one tiny deviation could ruin the entire batch.

This relentless, scientific focus on consistency and quality is the soul of Six Sigma.

While Lean is all about speed and flow, Six Sigma is laser-focused on eliminating defects and variability. The goal is to make your processes so consistent and predictable that they produce nearly perfect results every single time. And when I say "perfect," I mean it: the Six Sigma standard aims for a process to have fewer than 3.4 defects per million opportunities.

This methodology got its start in manufacturing but has since been embraced by virtually every industry on the planet. Its power comes from a highly structured, data-first approach called DMAIC:

Define: Clearly lay out the problem, the project goals, and what the customer actually needs.

Measure: Collect hard data to gauge the current process performance. No guesswork allowed.

Analyze: Dive into the data to pinpoint the root causes of defects and variations.

Improve: Develop and roll out solutions that tackle those root causes head-on.

Control: Monitor the new-and-improved process to make sure the gains stick around for the long haul.

A famous example is how General Electric adopted Six Sigma in the 1990s, leading to billions in savings and massive operational gains. It proved that Six Sigma is far more than a factory floor tool; it’s a globally recognized standard for achieving top-tier quality.

You’d turn to Six Sigma when quality is non-negotiable and the cost of a mistake is sky-high—think financial firms processing transactions, hospitals performing surgery, or software teams trying to squash critical bugs.

Kaizen: The Power of Compounding Improvements

Finally, think about a dedicated athlete training for a marathon. They don't just wake up one day and become a world-class runner. Instead, they make small, consistent improvements, day in and day out. Today, they might focus on their stride. Tomorrow, their breathing technique.

Over time, these tiny daily adjustments compound into a massive leap in performance. This philosophy of small, steady progress is Kaizen.

Kaizen is a Japanese term that translates to "change for the better" or "continuous improvement." Unlike Lean or Six Sigma, which are often rolled out as big, distinct projects, Kaizen is more of a cultural mindset. It’s about empowering every single employee—from the CEO down to the person on the front line—to constantly be on the lookout for small ways to make their work just a little bit better.

The core idea of Kaizen is that huge, transformative change can come from the accumulation of countless small, incremental improvements. It builds a culture where no process is ever considered "finished," and there's always room to refine it.

This approach is so powerful because it’s not intimidating. Asking an employee to find a way to shave 30 seconds off a daily task feels achievable. Asking them to redesign an entire workflow from scratch? Not so much. These small wins create momentum and get people engaged, building a powerful engine for constant growth. To put this into practice, you might find it helpful to explore the key process improvement techniques to use in 2025 that can help build a Kaizen culture.

Kaizen can be applied literally anywhere and works beautifully alongside both Lean and Six Sigma. It provides the cultural glue that makes sure improvements don't just happen once, but become a permanent part of how the company breathes and operates.

Choosing the Right Methodology for Your Business

Picking the right process improvement methodology feels a lot like standing in front of a giant toolbox. You wouldn’t grab a sledgehammer to fix a wristwatch, right? It’s the same idea here. The key is matching the tool—the methodology—to the specific problem you're trying to solve.

So, where do you start? It really boils down to your biggest headache. Are you constantly battling slow delivery times? Plagued by persistent product defects? Or maybe you’re just trying to spark some proactive energy in a company culture that’s gone a bit stale? Each framework—Lean, Six Sigma, and Kaizen—offers a very different path to get you where you need to go.

Comparing the Core Methodologies

Let's lay these three heavy-hitters side-by-side. Seeing how they differ in their focus, scope, and even the kind of data they demand will make it much clearer which one aligns with your company's immediate challenges.

Lean vs Six Sigma vs Kaizen At a Glance

The table below is a cheat sheet to help you quickly grasp the fundamental differences. Think of it as the "spec sheet" for each methodology.

Attribute | Lean | Six Sigma | Kaizen |

|---|---|---|---|

Primary Focus | Speed & Waste Elimination | Quality & Defect Reduction | Continuous Incremental Improvement |

Ideal Problem | Inefficient workflows, long lead times, excess inventory, and wasted motion. | High defect rates, process variation, and critical quality failures. | Stagnant processes, low employee engagement, and a need for a proactive culture. |

Project Scope | Can be both small-scale (a single workflow) and transformational (an entire value stream). | Typically large, structured projects with significant transformational goals. | Small, ongoing improvements made by teams at all levels. |

Data Needs | Relies heavily on direct observation, process mapping, and timing analysis. | Extremely data-intensive; requires rigorous statistical analysis and measurement. | Driven by observation and employee feedback, with less emphasis on complex data. |

Core Question | "How can we deliver value to the customer faster with less waste?" | "How can we make this process nearly perfect and eliminate all variation?" | "What small change can we make today to improve our work?" |

In short, this comparison highlights the unique strengths of each approach. If you need speed, Lean is your go-to. If you need perfection, look to Six Sigma. And if you want to build a culture of constant, small-step refinement, Kaizen is the answer.

Putting Methodologies into Practice

Abstract concepts are one thing, but seeing them in action is what really makes it click. Let's walk through a few real-world scenarios to see how different businesses would apply each process improvement methodology.

Scenario 1: The Logistics Firm

Imagine a delivery company drowning in late shipments and sky-high fuel costs. Customers are complaining, and operational expenses are eating every last bit of profit. The problem isn’t quality—the packages arrive in one piece—it's all about speed and efficiency.

Best Fit: Lean. This is a classic Lean problem. The company would use Lean tools to map its entire delivery process, from the moment a package hits the warehouse to when it lands on a doorstep. They'd hunt down and eliminate waste in all its forms: inefficient routes (transportation waste), excessive package handling (motion waste), and trucks sitting idle (waiting waste). The whole point is to streamline the flow, getting packages delivered faster and for less money.

Scenario 2: The Software Company

A tech startup just launched a slick new app, but users are reporting a flood of critical bugs. The dev team is trapped in a frustrating cycle of pushing out fixes that only seem to create new problems elsewhere. Their brand reputation is on the line.

Best Fit: Six Sigma. Here, the issue is purely about quality control and defect elimination. The company would fire up the DMAIC framework to Define what constitutes a "critical bug," Measure how often they occur, Analyze the code to pinpoint the root causes, Improve the development process to prevent them, and then Control the workflow to ensure they don't creep back in. The intensely data-driven nature of Six Sigma is perfect for untangling complex technical knots like this.

Scenario 3: The Established Retailer

Think of a retail chain that’s been doing things the same way for decades. Their processes work, but they aren't getting any better. Employee morale is flat, and nobody seems to have any new ideas. They aren't in a crisis, but they feel completely stagnant.

Best Fit: Kaizen. The goal here is cultural transformation. The retailer would launch a Kaizen program, encouraging every single employee—from cashiers to the stockroom crew—to suggest small, daily improvements. A cashier might suggest a smarter way to organize their register drawer, saving just a few seconds on every transaction. By themselves, these ideas are tiny. But when you multiply them across the entire company, they create huge long-term gains and foster a powerful culture of ownership and engagement.

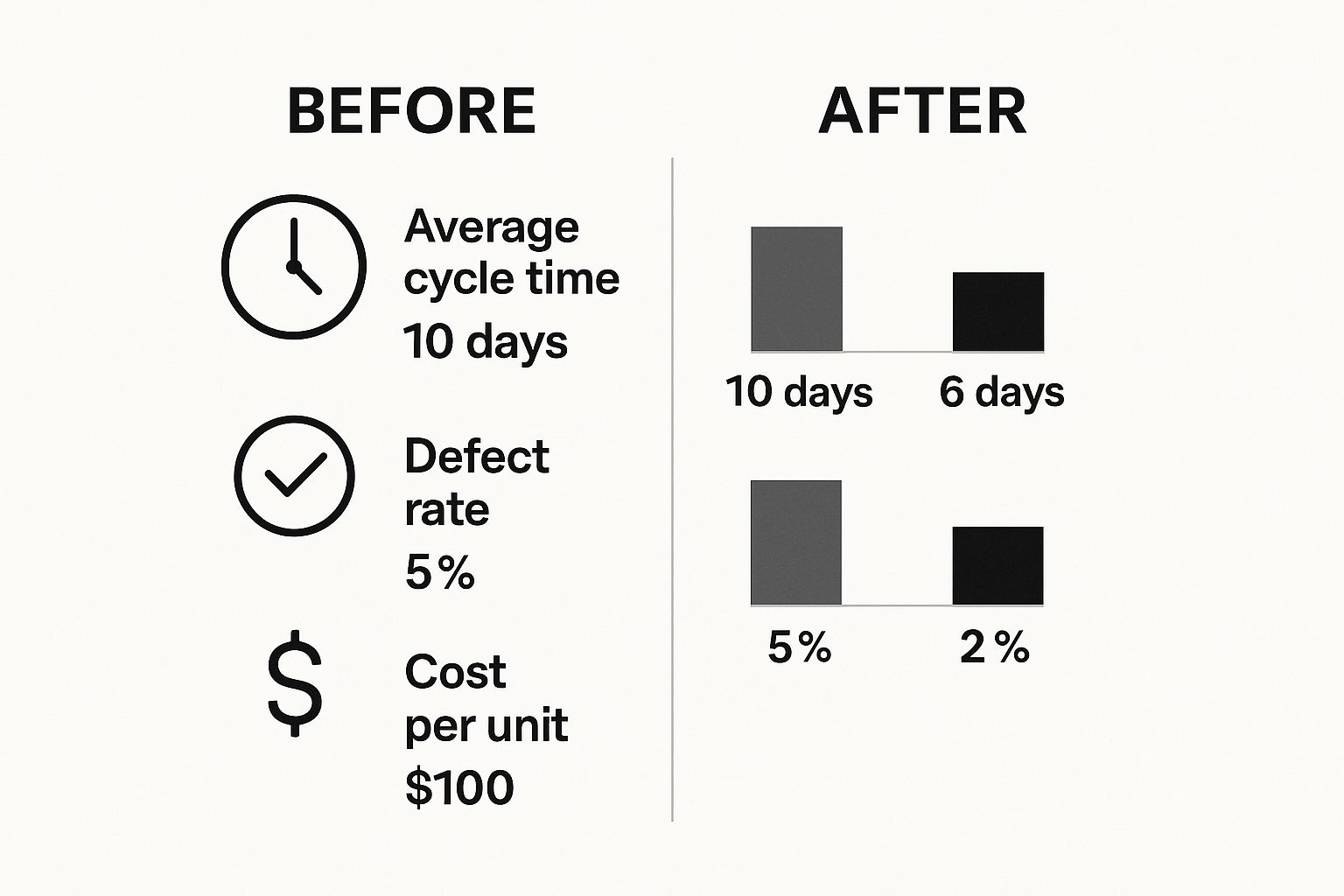

The right methodology can have a dramatic, measurable impact on the metrics that matter most.

As you can see, these initiatives drive real results, slashing cycle times and defect rates while bringing down operational costs. You can push these results even further by pairing them with smart automation. To see how technology can put your efforts on overdrive, check out our guide to digital process automation.

In my experience, the most powerful approach is often a hybrid one. A company might use Lean to redesign a clunky workflow, then bring in Six Sigma tools to perfect one critical step within that new process, all while fostering a Kaizen culture of continuous feedback from the front lines.

Ultimately, the best process improvement methodology is the one your team will actually use consistently. Start by identifying your single biggest pain point, and let that guide you to the framework designed to solve it.

Your First Steps in Process Improvement

Moving from knowing about a process improvement methodology to actually putting one to work can feel like a huge jump. But here’s the good news: you don’t have to transform the entire company overnight. The best, most lasting changes start small, proving their worth before you roll them out on a larger scale. This is how you close the gap between theory and reality.

The first, and most important, step is to get an honest diagnosis of your company's biggest headaches. You wouldn't take medicine without knowing what's wrong, right? So, are your main issues about quality, or are they really about inefficiency?

Diagnosing Your Primary Pain Point

Take a hard look at your daily operations. Are you dealing with defects, or are you drowning in waste?

Signs of a Quality Problem: This is where Six Sigma shines. You’re likely facing a quality issue if you’re seeing frequent customer complaints, high product return rates, or spending a lot of time and money on rework to fix mistakes. The core problem is inconsistent results.

Signs of a Waste Problem: This is classic Lean territory. You probably have a waste problem if your team talks about long delays, clunky handoffs between people, or workflows that are bogged down with endless manual steps. It's all about slow, inefficient movement.

Answering that one question gives you a powerful starting point. It helps you aim your efforts where they’ll make the biggest difference, ensuring your first project tackles a real, painful issue. As you get started, a solid guide can offer a great framework; for example, a guide on how to improve fleet efficiency details foundational steps that apply across many different industries.

Assembling Your Team and Securing Buy-In

Once you’ve identified your target, you need a team. And just as crucial, you need permission. Process improvement can’t be a secret project run from a basement office; getting leadership's support is non-negotiable.

Don't pitch an abstract "improvement project." To get executives on your side, frame the initiative as a direct solution to a business problem. Tie your pilot project to the numbers they care about, like reducing operational costs by 15% or cutting down customer delivery times.

With leadership's blessing, build a small, dedicated team. This group can't just be managers. You absolutely must include the people who do the work day in and day out. Their firsthand knowledge is pure gold for spotting the real sources of friction and for coming up with practical solutions that will stick.

Defining Your Pilot Project

The secret to building momentum is to start with a manageable pilot project—one with a high chance of success. Your objective is to score an early, visible win that clearly shows the value of using a process improvement methodology.

Here’s how to pick a winning pilot project:

Define a Clear Scope: Choose one, well-defined process. "Improve customer onboarding" is a much better start than "fix the sales department."

Ensure It's Measurable: Pick a process where you can easily track the before-and-after numbers. You need data to prove you made a difference.

Focus on High Impact: Go after a problem whose solution will be widely felt, either by easing a common frustration for employees or by noticeably improving a customer experience.

Finally, talk about what you're doing. All the time. Keep everyone in the loop on the project's goals, its progress, and its results. Great communication turns skepticism into enthusiastic support, building a culture where change isn't just tolerated—it's welcomed as the way to a better, smarter way of working for everyone.

Measuring the True Impact of Better Processes

Let's be honest: successful process improvement isn't just about feeling more organized. It's about delivering real, measurable results that echo from the front lines all the way to the C-suite. Thinking of a process improvement methodology as an expense is missing the point entirely. It’s a strategic investment, and one that should pay for itself many times over.

The most obvious wins show up right on the balance sheet. These are the hard-number victories that get everyone's attention. When you systematically hunt down and eliminate waste, you start seeing significant financial gains. Your operational costs drop, production cycles get shorter, and you spend far less time and money fixing mistakes. It's a simple equation: better processes mean you use fewer resources to get a superior result, which directly fuels profitability.

Beyond the Bottom Line: The Softer Wins

But if you only focus on the financials, you're missing half the story. The "soft" benefits, while trickier to slap a dollar sign on, are just as vital for the long-term health and growth of your company. These are the changes that reshape your culture and sharpen your competitive edge.

Think about what happens when you remove the daily roadblocks that frustrate your team. When people are empowered to do their best work without constantly fighting broken systems, their morale and engagement naturally climb. They shift from being passive observers to active participants in making things better, which fosters a much more proactive and positive environment.

At the same time, as your processes become more reliable, customer satisfaction skyrockets. Faster delivery, higher-quality products, and fewer service hiccups are the building blocks of fierce brand loyalty. This newfound agility also means you can pivot much faster than your competitors when the market shifts, turning potential threats into genuine opportunities.

The Undeniable ROI of Systematic Improvement

The link between structured improvement and business success isn't just a theory; it's backed by a mountain of data. Companies that truly commit to these frameworks see incredible returns. The numbers don't lie.

A landmark study from the International Quality and Productivity Center (IQPC) found that companies focused on continuous improvement see an average 20% increase in operational efficiency in the first year alone. Stick with it for five years, and those numbers get even more impressive: a 40% reduction in defects, a 30% drop in operational costs, and a 25% jump in customer satisfaction. You can dig deeper into these findings over at Prosci.com.

These statistics paint a very clear picture. Committing to a process improvement methodology like Lean or Six Sigma isn't about making a few small tweaks here and there. It’s about building a powerful engine for sustained excellence that drives profit, delights customers, and engages your entire workforce.

Ready to start tracking these kinds of results? Our guide on how to measure operational efficiency beyond basic metrics is the perfect place to start. Ultimately, measuring the true impact means looking at both the hard data on the spreadsheet and the cultural shift happening on your factory floor or in your office.

Common Questions About Process Improvement

As soon as you start digging into the world of process improvement methodologies, a bunch of questions pop up. It’s only natural. Getting straight, practical answers is the first step to making a smart decision and setting your team up for a win.

So, let's tackle some of the most common questions I hear from teams just starting their journey.

Can I Combine Different Methodologies?

Absolutely. In fact, cherry-picking and combining methodologies is often the most powerful way to go. It lets you play to the strengths of each framework. The classic example is Lean Six Sigma, which blends Lean’s obsession with speed and waste elimination with Six Sigma’s data-heavy approach to stamping out defects.

Think of it this way: You’re building a custom workshop. Lean helps you lay out the tools and workflow to get projects done with zero wasted steps. But you might pull in a Six Sigma tool to calibrate a specific, critical piece of machinery to perfection, ensuring every cut is flawless.

You can also sprinkle a Kaizen mindset of daily, incremental improvements over any bigger project. The real magic happens when you stop trying to follow one playbook religiously and start picking the right tool for the job at hand.

This kind of flexibility gives you a much richer toolkit to solve complex problems, hitting both efficiency and quality at the same time.

Is This Only for Big Manufacturing Companies?

That’s probably the biggest myth out there. While it’s true that many of these ideas were born on the factory floor—Six Sigma at Motorola, Lean at Toyota—their core principles work for any business with a process. And let's be honest, that’s every business.

The goal is always the same: find a better way to get work done. The context just changes.

Healthcare: A hospital can use Lean to map the patient journey and drastically cut down ER wait times.

Finance: A bank can apply Six Sigma to find and fix errors in its loan approval workflow, lowering risk and making customers happier.

Technology: A software startup can build a Kaizen culture to roll out small, continuous product updates based on what users are actually asking for.

If it’s a process, it can be improved. It doesn't matter if you're making a car, serving a client, or shipping code.

What Does It Cost to Get Started?

The investment can range from practically nothing to a whole lot. A full-blown, company-wide Six Sigma rollout with certified Black Belts and formal training programs can be a major expense. But you don't have to start there. Not at all.

The best way to begin is to start small. Pick one nagging problem and run a pilot project. You might use some basic Lean principles, which could cost you nothing more than your team’s time and some insights from free online resources.

Your goal for that first project should be a clear return on investment. If you choose wisely, the project should deliver savings or efficiencies that more than cover the effort. That quick win proves the value of the approach and builds a solid business case for doing more. It stops being a "cost" and becomes a smart investment in your company's future.

How Do I Get My Team On Board?

Any time you talk about changing how people work, you're going to hit some resistance. It’s human nature. The secret to getting buy-in is to stop pushing and start pulling. Don't dictate a new methodology from on high—that’s a guaranteed way to fail.

Instead, make your team part of the solution from day one. Frame it as a group effort to fix the things that frustrate them every single day. Ask questions like:

What’s the biggest time-waster in your day?

Are there any tasks that feel completely pointless?

Where do things always seem to get stuck?

When you position process improvement as a way to make their jobs easier and more meaningful, you turn skeptics into champions. They get on board because they can see what’s in it for them. That’s how you build a culture that truly wants to get better, every single day.

At Flow Genius, we specialize in turning these improvement principles into reality through smart automation. We design and implement custom workflows that eliminate the manual, repetitive tasks holding your business back, freeing your team to focus on high-impact work. Discover how Flow Genius can automate your path to peak efficiency.