Boost Efficiency with Automated Inventory Management

- May 20, 2025

- 10 min read

The New Era of Automated Inventory Management

Outdated inventory practices often result in significant financial losses for businesses. These losses come from common issues like overstocking, stockouts, and inaccurate forecasting. Automated inventory management offers a critical solution to these challenges. This approach represents a significant shift from traditional manual methods and is reshaping operations across diverse industries.

Driving Forces Behind the Automation Shift

Several key factors contribute to the growing adoption of automated inventory management. The increasing complexity of modern supply chains demands more sophisticated tools. The rise of e-commerce has also intensified the pressure for faster order fulfillment and accurate inventory data.

Advancements in technology, particularly in Artificial Intelligence (AI) and Machine Learning (ML), have made automated solutions more accessible and powerful. Businesses can now leverage data to improve decision-making and gain a competitive edge.

For example, AI-powered systems can analyze sales trends and predict future demand with greater accuracy than traditional methods. Exploring how automation is applied in other areas, like customer service, can offer valuable insights. Learn more about how to automate customer service.

The Impact of AI on Inventory Management

The role of AI in optimizing inventory is especially significant. The global market for AI in inventory management has experienced substantial growth, reaching $7.38 billion in 2024. Projections indicate continued expansion to $9.6 billion by 2025 and a remarkable $27.23 billion by 2029, with a CAGR of 29.8%.

Several factors fuel this growth. These include the increasing number of retail stores, the integration of technologies like blockchain and augmented reality, and the critical role of AI in managing complex supply chains, particularly in improving accuracy and forecasting. You can find more detailed statistics here.

Automated systems can also streamline other critical aspects of operations. These include better management of warehouse space and improved efficiency in picking and packing processes. Ultimately, these advancements lead to cost reductions and faster delivery times, highlighting the powerful impact of AI in streamlining inventory management.

Unlocking Tangible Benefits That Drive Bottom-Line Growth

Automated inventory management systems offer numerous advantages. They go beyond theoretical benefits to deliver measurable bottom-line improvements. These systems directly address the costly challenges of outdated inventory practices, transforming how businesses operate and compete.

Cost Reduction and Increased Efficiency

One of the most significant advantages of automated inventory management is substantial cost savings. By optimizing stock levels, businesses can reduce holding costs for storing excess inventory. This efficiency also impacts labor costs. Automation eliminates manual processes such as stocktaking and data entry.

Some businesses have reported labor cost reductions of up to 65% after implementing these systems. This allows staff to focus on higher-value tasks that contribute to business growth.

Improved Accuracy and Reduced Errors

Automated systems drastically improve inventory accuracy by minimizing human error. This leads to fewer discrepancies between actual and recorded stock levels. Consequently, businesses can avoid stockouts, which can damage customer relationships and lead to lost sales.

Accurate inventory data enables better forecasting and planning. This allows for informed decisions about purchasing and production. Automated inventory management systems are increasingly vital for businesses seeking operational optimization. Learn more about automated inventory management systems.

Enhanced Customer Satisfaction

Faster fulfillment and near-perfect inventory accuracy improve customer satisfaction. When orders are processed quickly, customers have a more positive brand experience. This can increase customer loyalty and generate positive word-of-mouth referrals. You might be interested in: How to streamline operations and boost efficiency.

Scalability and Growth

The benefits of automated inventory management scale with business size and complexity. However, regardless of size, automation provides a foundation for growth. For small businesses, it offers the efficiency needed to compete with larger players. For enterprises, it offers control and visibility for managing complex supply chains.

To illustrate the benefits of automated inventory management, let's look at a comparison between manual and automated systems. The following table highlights key differences across critical performance metrics.

Manual vs. Automated Inventory Management Comparison

Performance Metric | Manual Inventory Management | Automated Inventory Management | Improvement Percentage |

|---|---|---|---|

Accuracy | Prone to human error, typically 70-80% accuracy | High accuracy, often exceeding 99% | 20-29% |

Labor Costs | High, requiring significant staff for manual tasks | Reduced significantly, up to 65% cost reduction | Up to 65% |

Order Fulfillment Time | Slower, often with delays due to manual processes | Significantly faster, enabling same-day or next-day shipping | Can be reduced by 50% or more |

Stockout Rate | Higher due to inaccurate inventory data | Lower, minimizing lost sales and customer dissatisfaction | Can be reduced by 80% or more |

Inventory Holding Costs | Higher due to overstocking and inefficient storage | Optimized stock levels leading to reduced holding costs | Can be reduced by 20-30% |

This table showcases how automated inventory management systems can significantly enhance key performance metrics. The improvements in accuracy, labor costs, order fulfillment, stockout rates, and inventory holding costs contribute to increased efficiency, profitability, and customer satisfaction. By automating these crucial processes, businesses can unlock significant benefits that drive bottom-line growth and strengthen their competitive position in the market.

The Technology Ecosystem Powering Modern Inventory Solutions

Building on the advantages of modern inventory solutions, let's explore the technologies driving these advancements. These tools empower businesses to transition from manual processes to data-driven inventory management.

Core Technologies Driving Automation

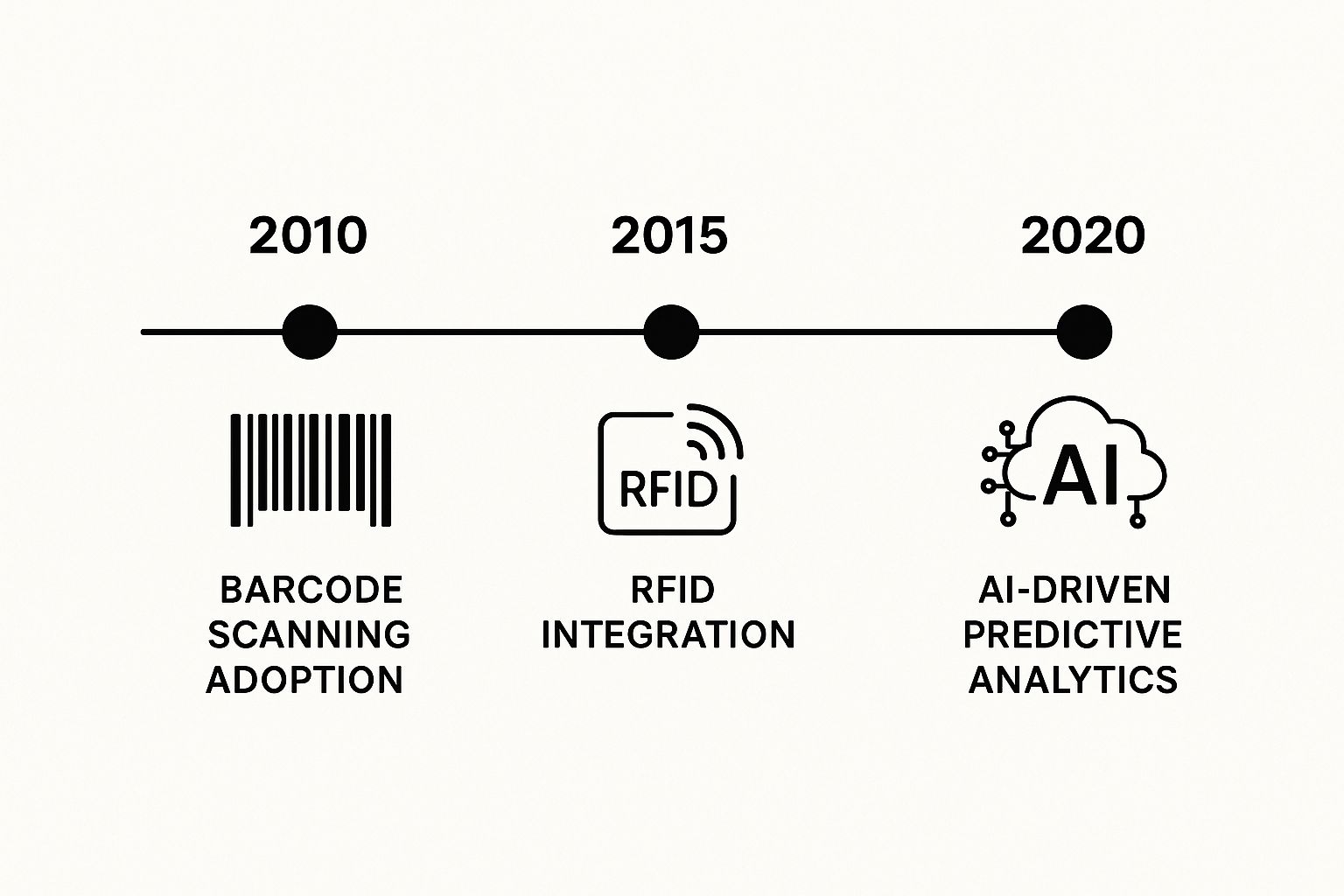

Modern automated inventory management systems rely on a combination of powerful technologies. These range from established systems like barcodes to more recent innovations like AI-powered predictive analytics.

Barcode and RFID Systems: These technologies automate data collection throughout the supply chain, offering high accuracy. RFID (Radio-frequency identification) tags, specifically, enable tracking of individual items without direct line-of-sight scanning. This constant data flow significantly improves overall visibility.

IoT Sensors: IoT (Internet of Things) sensors provide real-time data on environmental conditions, stock levels, and product location within a warehouse. This granular level of detail is critical for businesses handling perishable goods or sensitive materials.

Cloud Platforms: Cloud technology connects all parts of the automated inventory ecosystem, enabling seamless data sharing and collaboration. This also facilitates easy scalability as a business expands.

Integration and Connectivity

Effective automated inventory management hinges on seamless integration with existing business systems. Connecting inventory systems to Enterprise Resource Planning (ERP) systems, Point of Sale (POS) systems, and e-commerce platforms ensures smooth data flow across the organization. This interconnectedness eliminates data silos and enhances decision-making regarding forecasting, purchasing, and order fulfillment. For further information, check out this article on How to automate inventory with Zapier.

Addressing Security and Scalability

Data security is paramount in any automated system. Modern inventory solutions employ robust security measures to protect sensitive data. Equally crucial is the system's ability to handle peak demand, like holiday shopping seasons. Scalability guarantees the system can grow with the business, maintaining performance. The growing use of advanced technologies like warehouse management systems (WMS) has significantly improved inventory management. WMS automates core warehouse operations such as inventory tracking, order fulfillment, and shipping management. This real-time monitoring minimizes errors and boosts efficiency.

WMS tools also optimize picking and packing processes, assist with workforce scheduling, and even generate shipping labels. These efficiencies contribute to reduced labor costs and improved profitability. The global warehouse automation market, encompassing WMS, is expected to reach nearly CA$60 billion by 2027, demonstrating the rising adoption of these technologies. You can find more detailed statistics here. To explore the impact of technology further, consider the advancements in AI-Powered Retail Inventory Management.

Your Implementation Roadmap for Automated Inventory Success

The infographic above charts the journey of automated inventory management. Key milestones, such as the widespread use of barcode scanning around 2010, the integration of RFID technology circa 2015, and the rise of AI-powered predictive analytics by 2020, illustrate how these systems have become more sophisticated and capable. These advancements have consistently improved the efficiency and accuracy of managing inventory, providing a valuable framework for businesses looking to implement similar solutions.

Assessing Your Needs and Defining Objectives

The first step toward successful automated inventory management is a comprehensive needs assessment. This involves pinpointing current inventory challenges and setting SMART objectives: Specific, Measurable, Achievable, Relevant, and Time-bound. Ask yourself key questions: What are your biggest pain points? Where are the bottlenecks? Are stockouts, overstocking, or inaccurate forecasting recurring issues? Defining your needs and goals will guide your system selection and ensure it aligns with your business requirements.

Evaluating and Selecting the Right System

After identifying your needs, evaluate potential automated inventory management systems. Consider factors like available features, scalability, integration capabilities with existing systems like ERP and POS systems, and overall cost. Seamless integration with your current platforms, such as your ERP, POS, and e-commerce platforms, is crucial. Robust reporting and analytics features are essential for gaining valuable insights into inventory performance.

Phased Rollout and Data Migration

Implementing a new system should be a phased process to minimize disruptions. Start with a pilot program, perhaps in a specific warehouse section or with a limited product line. This allows you to test the system, identify any issues, and refine processes before a full-scale launch. Data migration is critical. A clean, accurate transfer of existing inventory data to the new system is essential to avoid costly errors.

Change Management and Training

Successful implementation requires team buy-in. Address any employee concerns, provide thorough training, and ensure everyone understands how to use the new system effectively. Ongoing support and clear communication are key to smooth adoption.

Measuring Success and Continuous Improvement

After implementation, track key performance indicators (KPIs) such as inventory accuracy, order fulfillment time, and carrying costs to gauge success. Regular performance monitoring, team feedback, and necessary adjustments will optimize the system and help achieve your desired ROI.

Real-World Examples and Case Studies

Many businesses have seen significant benefits from automated inventory management. Some companies have reduced inventory holding costs by 20-30% and improved order fulfillment rates by 50% or more. These results demonstrate the potential for substantial improvements in efficiency and profitability. For more information on automating workflows, see automating your business with custom solutions.

The following table provides a general timeline for implementing an automated inventory management system. While every implementation is unique, this provides a helpful framework for understanding the process.

Automated Inventory Management Implementation Timeline

Implementation Phase | Key Activities | Estimated Duration | Critical Success Factors |

|---|---|---|---|

Needs Assessment & Planning | Define objectives, analyze current processes, determine requirements | 2-4 weeks | Clear objectives, stakeholder involvement, accurate data analysis |

System Selection & Vendor Evaluation | Research vendors, demos and trials, contract negotiation | 4-8 weeks | Comprehensive vendor evaluation, alignment with business needs |

System Configuration & Customization | System setup, data mapping, customization to specific business processes | 6-12 weeks | Detailed planning, effective communication with vendor |

Data Migration & Testing | Data transfer, system testing, user acceptance testing | 4-6 weeks | Data cleansing and validation, thorough testing procedures |

Deployment & Training | System rollout, user training, go-live support | 2-4 weeks | Comprehensive training program, effective change management |

Post-Implementation Review & Optimization | Performance monitoring, system adjustments, ongoing support | Ongoing | Regular performance reviews, continuous improvement mindset |

This timeline emphasizes the importance of planning, data accuracy, and change management for a successful implementation. Remember, ongoing review and optimization are essential for maximizing the benefits of your automated inventory management system.

Harnessing AI for Inventory Forecasting That Actually Works

Beyond basic automation, predictive inventory management, powered by AI and machine learning, is transforming inventory forecasting. We're moving from educated guesses to data-driven certainty. This shift allows businesses to anticipate demand with greater precision, optimizing inventory levels and boosting profitability.

AI-Powered Predictive Analytics

Leading organizations use AI and machine learning to analyze complex patterns from a variety of data sources. These sources can include historical sales data, market trends, and even weather patterns and social media activity. For instance, an online retailer could use AI to analyze the social media buzz around a new product launch. This analysis helps predict initial demand and ensures there's enough stock on hand.

This detailed analysis lets businesses go beyond simply extrapolating from past trends. They can account for many different factors that influence demand. The result is more accurate forecasts and a reduced risk of both overstocking and running out of stock. These insights allow for proactive adjustments to inventory, minimizing the need for reactive measures.

Real-World Impact of AI-Driven Forecasting

The advantages of AI-driven forecasting are significant. Businesses have reported reducing carrying costs by up to 30% simply by optimizing inventory levels and minimizing excess stock. AI can also practically eliminate stockouts, even during peak demand periods. This ensures customer satisfaction and protects revenue streams.

AI also improves capital allocation across product lines. By accurately predicting the demand for each product, businesses can allocate resources more efficiently. This leads to a maximized return on investment. These results show that AI-driven forecasting isn't just a technological advancement. It's a strategic tool for increasing both business growth and profitability.

Demystifying the AI Technologies

Specific AI technologies are key to these improvements. Neural networks, for example, can identify complex, non-linear relationships in data. Regression models can predict future values based on historical data trends.

The focus, however, isn't on the complex technical details of these tools. The key takeaway is how these technologies translate into tangible business results. A business can focus, for instance, on the reduction in storage costs achieved through AI-optimized inventory. They don't need to worry about the intricacies of the underlying algorithms. This practical approach emphasizes the value and impact of AI without needing a deep technical understanding. By grasping the potential of AI-driven forecasting, businesses can make informed decisions and significantly improve their inventory management.

Future-Proofing Your Automated Inventory Strategy

The inventory management world is constantly evolving. Is your business prepared for the future? This section explores emerging technologies set to reshape inventory operations in the coming years. We'll examine which technologies offer a real return on investment (ROI) and which are still developing. Most importantly, we'll provide a framework for deciding when to adopt new tools, ensuring your automated inventory management strategy stays ahead of the curve without chasing every fad.

Blockchain for Enhanced Transparency and Security

Blockchain technology, renowned for its security and transparency, is building tamper-proof supply chains. Imagine a system where every transaction, from raw materials to finished goods, is permanently recorded on a shared, immutable ledger. This eliminates fraud and counterfeiting while providing complete visibility into product origins. For instance, a food company could use blockchain to track every ingredient from farm to table, assuring consumers about product origin and quality.

This enhanced transparency builds consumer trust and strengthens brand reputation. With blockchain, businesses can demonstrate a commitment to ethical sourcing and product safety.

The Rise of Autonomous Robots and Drones

Autonomous robots and drones are changing how we count inventory. These technologies automate what used to be a labor-intensive and error-prone process. Drones can scan thousands of items in minutes, delivering real-time data on stock levels. Robots can navigate warehouses independently, retrieving items for orders and restocking shelves. This allows human workers to focus on more strategic tasks and significantly boosts efficiency.

The increased speed and accuracy of automated inventory counts minimizes stockouts and overstocking, leading to significant cost savings.

Augmented Reality for Improved Picking and Training

Augmented reality (AR) is improving picking accuracy and training. Imagine warehouse workers wearing AR glasses that project digital information onto their view of the real world. These glasses can direct workers to item locations, show picking instructions, and even provide instant performance feedback. This increases picking speed and reduces errors, while also making training for new employees more efficient. Check out our guide on automating your business with custom solutions: Automating Your Business With Custom Solutions.

AR technology empowers workers with real-time information and guidance, leading to a more productive and engaged workforce.

Evaluating Emerging Technologies: A Practical Framework

Not every new technology is right for every business. Here’s a framework for evaluating emerging technologies for your automated inventory management strategy:

Business Needs: Identify your specific challenges. Are you struggling with inventory accuracy? Is your supply chain opaque? Focus on technologies that address your unique issues.

ROI: Does the technology provide a clear return on investment? Analyze implementation costs, potential savings, and the overall impact on efficiency.

Scalability: Can the technology grow with your business? Select solutions that adapt to your changing needs.

Integration: Does the technology integrate with your existing systems? Seamless integration prevents data silos and optimizes efficiency.

By applying this framework, you can make informed decisions about technology adoption, ensuring your automated inventory management strategy remains effective and forward-thinking. It's about choosing the right tools at the right time to maximize your business impact.

Ready to transform your inventory management and improve efficiency? Flow Genius offers expert automation consulting and implementation services, helping businesses eliminate manual processes and achieve scalable growth. Visit Flow Genius today to learn more and schedule a consultation.

Comments