Supply Chain Automation Solutions That Actually Work

- Matthew Amann

- Jun 17, 2025

- 16 min read

Understanding Your Automation Readiness

Let's talk supply chain automation. Before you jump in headfirst, it's really important to take a good, honest look at where your operations stand today. I've chatted with tons of operations directors who've navigated these transformations, and one thing they all emphasize is readiness. It's easy to get swept up in the excitement of new tech, but without a solid operational foundation, those shiny new tools can lead to expensive flops. Think of it like building a house – a fancy exterior won't hold up if the foundation is crumbling.

This screenshot shows how interconnected a typical supply chain really is. It highlights the flow of everything – information, materials, and money – and serves as a good reminder that automating one piece without considering the others can just create new bottlenecks. A big-picture perspective is essential when you’re assessing your readiness.

Evaluating Your Data Landscape

One trap I see people fall into a lot is overlooking data quality. Companies often assume their data is pristine and ready for automation, only to uncover inconsistencies, gaps, and errors that throw the whole project off track. Remember, accurate, standardized data is the fuel that powers any automation system. Garbage in, garbage out, right? So before you implement any new tech, make data cleansing and standardization a top priority.

Assessing Team Capacity and Bandwidth

Another often-underestimated factor is your team's bandwidth. Implementing and managing new systems takes serious time and effort. Is your team already overloaded? Do they have the capacity to learn new tools and processes? I once talked to an operations manager whose team felt completely swamped by a sudden wave of new technology. It really hurt their morale and productivity. This highlights how important it is to carefully consider your team’s current workload and provide them with proper training and support.

Infrastructure and Integration Considerations

Here’s another one: many organizations don't fully grasp the infrastructure needs for effective automation. Do your current systems play nicely with new technologies? Will you need to upgrade your hardware or software? These hidden costs can really throw a wrench in the works if you don't account for them in your initial budget. I know of one company that discovered their existing Warehouse Management System (WMS) wasn't compatible with their new automated picking robots. The result? Major delays and a bunch of unexpected expenses. And speaking of warehouse automation, the market is booming. It was valued at $26.5 billion in 2024 and is expected to grow at a 15.9% CAGR between 2025 and 2034. That shows serious investment and adoption across industries. You can read more about that growth here: Warehouse Automation Market Growth. Understanding these trends helps you see where your automation journey fits within the bigger industry picture. Careful planning and a deep understanding of your current infrastructure are key to success.

To help you really nail this assessment, I've put together a handy framework.

This table, the "Automation Readiness Assessment Framework," is a detailed checklist that evaluates key operational, technical, and organizational factors to gauge your readiness for automation. It helps you pinpoint areas where you're already in good shape and where you might need to focus your efforts.

Assessment Area | Key Indicators | Readiness Level | Next Steps |

|---|---|---|---|

Data Quality | Data completeness, accuracy, consistency, standardization | Low/Medium/High | Data cleansing, standardization, migration |

Team Capacity | Existing workload, skill gaps, training needs | Low/Medium/High | Training programs, resource allocation, workload adjustments |

Infrastructure | System compatibility, hardware/software capabilities, network bandwidth | Low/Medium/High | System upgrades, integration planning, scalability assessment |

Organizational Alignment | Stakeholder buy-in, change management processes, communication strategy | Low/Medium/High | Stakeholder workshops, communication plan development, change management training |

Looking at this framework and honestly evaluating each area will give you a much clearer picture of your true automation readiness. This upfront work may seem tedious, but trust me, it’s far better to address these things now than to run into problems down the road. So, before you invest in the latest supply chain automation solutions, take a hard look at your current operations. Honest self-assessment is the first step towards a successful automation journey.

Finding The Right Technology For Your Reality

So, you’re thinking about automating your supply chain. You’ve done your homework, assessed your needs, and you're ready to take the plunge. Great! Now comes the fun part (and maybe a little bit of a headache): picking the right tech. Let me tell you, those glossy brochures and sales demos don’t always tell the whole story. What worked for your competitor might not be the best fit for your operation.

Before you even start browsing solutions, it's essential to optimize what you already have. Improving your current systems, like focusing on inventory optimization with data intelligence, sets a solid foundation for automation. It’s all about understanding your specific operational needs. Don't just chase the latest gadgets – find the tools that actually solve your problems.

Cutting Through The Marketing Hype

I've seen firsthand how companies get seduced by slick marketing, only to end up with expensive systems that don't deliver. They invested in the hype instead of focusing on practical solutions. Trust me, your goal is to improve your operations, not impress the boardroom with the latest buzzwords. Sometimes, a simple conveyor belt upgrade will do more for your bottom line than some fancy AI-powered platform. It all comes down to what actually works for your business.

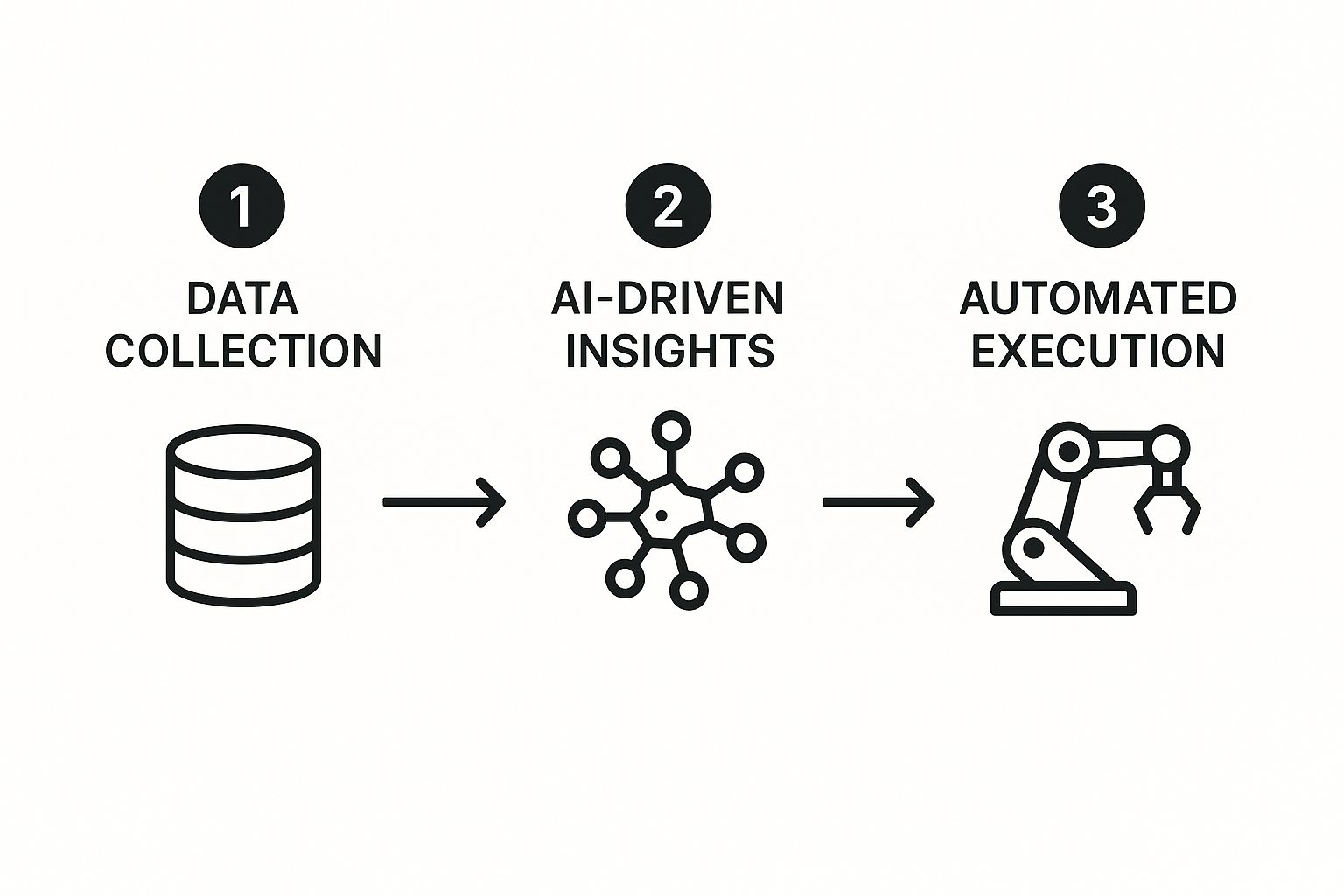

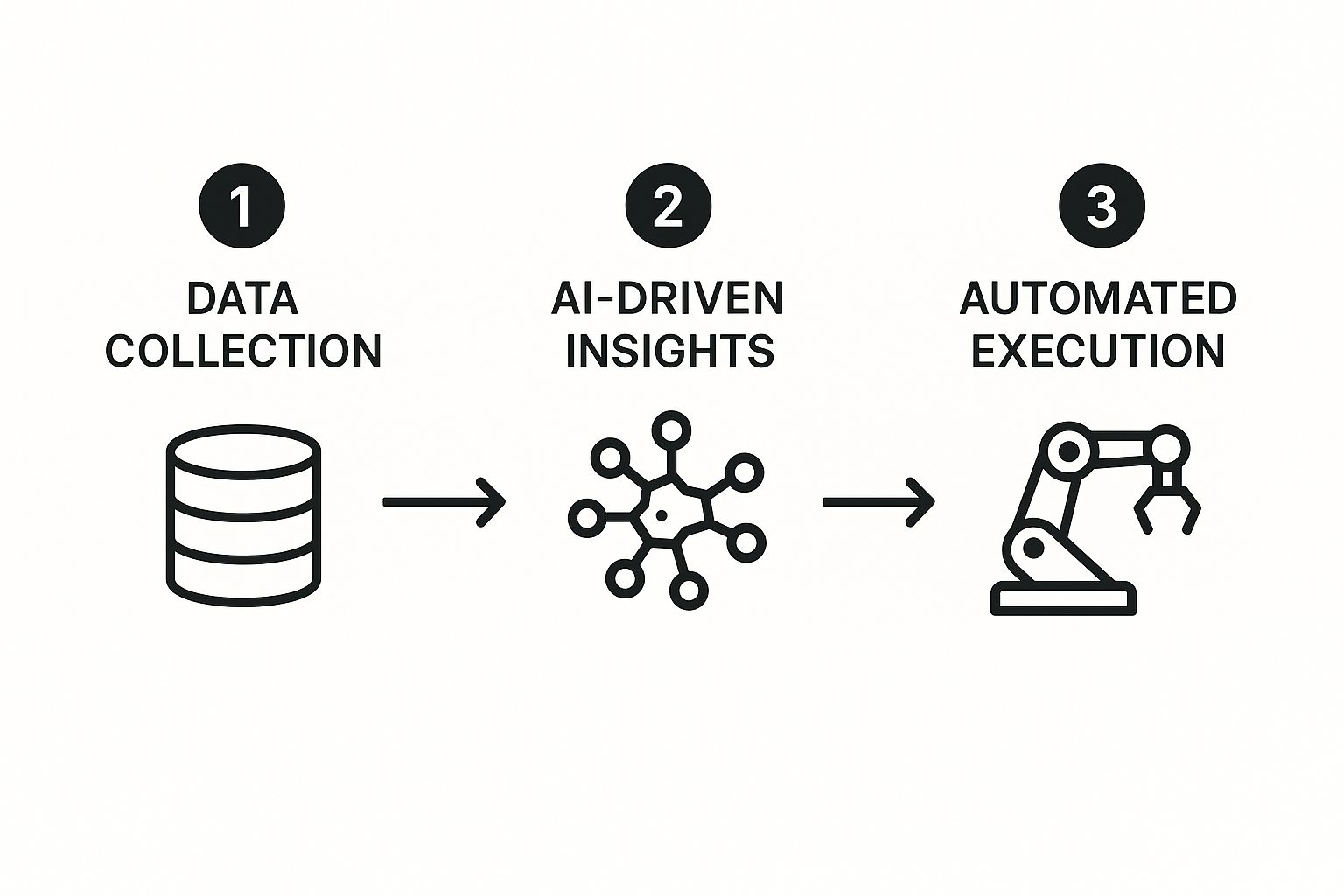

This infographic shows the core flow of automated systems: Data Collection feeds into AI-Driven Insights, leading to Automated Execution. Notice how important data is. Garbage in, garbage out, right? Even the smartest AI can't work miracles with bad data.

Evaluating Vendors Who Get Your Business

Choosing the right vendor is just as crucial as the technology itself. Look for partners who get your industry and understand your challenges. Ask tough questions about their experience with similar businesses. A good vendor will work with you, not just sell to you. They'll be invested in your success.

This screenshot shows a typical Warehouse Management System (WMS) interface. These systems can be incredibly powerful, but they need to integrate with your existing setup. A good WMS can be a game-changer, but a poorly integrated one can be a real nightmare.

Emerging Technologies vs. Proven Solutions

It's easy to get swept up in the excitement of emerging technologies. Blockchain, advanced robotics – it all sounds amazing, right? But are they ready for prime time in your operations? Don't get caught up in the hype cycle. Focus on proven solutions that can deliver real value today. Robotics is definitely gaining traction; by 2025, the annual growth rate is projected to hit 14%, with over 4 million robots in over 50,000 warehouses globally. Check out these supply chain statistics for more. While this growth is impressive, it's still crucial to assess if it's the right move for your business.

The following table provides a comparison of some key supply chain automation technologies:

Supply Chain Automation Technology Comparison: Detailed comparison of major automation technologies including implementation complexity, cost ranges, and best use cases

Technology Type | Implementation Time | Cost Range | Best For | ROI Timeline |

|---|---|---|---|---|

Warehouse Management System (WMS) | 6-18 months | $50,000 - $1 million+ | Inventory management, order fulfillment, warehouse operations | 12-24 months |

Transportation Management System (TMS) | 3-12 months | $20,000 - $500,000+ | Route optimization, freight management, carrier selection | 6-18 months |

Robotics (e.g., AGVs, AMRs) | 3-6 months | $100,000 - $1 million+ | Repetitive tasks, material handling, warehouse automation | 12-36 months |

Artificial Intelligence (AI) | Varies widely | Varies widely | Demand forecasting, inventory optimization, supply chain planning | Varies widely |

Blockchain | Varies widely | Varies widely | Supply chain transparency, traceability, security | Varies widely |

This table gives you a quick overview of some popular options, but remember, these are just estimates. Your actual costs and timelines will depend on your specific needs and implementation choices.

Avoiding Over-Engineering and Embracing Simplicity

One final piece of advice: keep it simple. I've seen companies build incredibly complex systems when a simpler approach would have worked just as well (and cost a lot less). Start small, test your solutions, and gradually add complexity as needed. This lets you refine your strategy without risking a major disruption to your operations. By focusing on practical solutions, carefully vetting your vendors, and staying grounded in your operational needs, you can successfully navigate the world of supply chain automation and choose the technologies that will genuinely benefit your business.

Designing Workflows That Your Team Will Actually Use

This is where so many supply chain automation projects stumble. Instead of fixing broken processes, companies often just try to automate them. It's like slapping a new engine in a car with a blown transmission—looks fancy, but you're not going anywhere. I've worked with a lot of operations teams, and the successful ones all agree: fix the foundation first.

This image shows how interconnected a modern supply chain really is. Each point is a potential problem or an automation opportunity. Redesigning workflows means looking at the whole system, not just individual parts.

Mapping Your Current Processes Honestly

Before even considering automation, you need a deep understanding of your current processes. This isn't about official documentation; it's about talking to the people on the ground. They know the real bottlenecks and inefficiencies. I once worked with a warehouse team whose official receiving process was completely bypassed due to outdated software. Automation wouldn't have fixed the core issue.

Identifying Costly Inefficiencies

After mapping your workflows, pinpoint the biggest time and money drains. These are your automation priorities. Think manual data entry, redundant approvals, mountains of paperwork. These are often the easiest targets for quick automation wins.

Designing New Workflows With Automation in Mind

This is the exciting part: designing new workflows that use automation to its fullest. Explore different Workflow Automation Solutions and think about how technology can streamline processes, remove unnecessary steps, and improve accuracy. But, and this is critical, involve your team. Their input is invaluable, since they'll be the ones using these workflows.

Testing and Refining Before Committing

One of the biggest pitfalls is investing in pricey technology without proper testing. A pilot program is crucial. It helps you find problems and refine processes before full commitment, plus it lets your team adjust to the new ways of working.

Building in Flexibility for the Future

Business is always changing, so your workflows need to adapt. Build in flexibility from day one. Think about modular automation systems that can be easily reconfigured as your needs change. This will prevent future headaches.

Phasing Implementations for Minimal Disruption

Don’t try to automate everything at once. A phased approach is far less disruptive. Start small, and gradually expand your automation efforts as you gain experience and confidence. I've seen companies maintain productivity during major workflow overhauls by phasing implementations carefully and providing ongoing support. By focusing on these key areas, you'll build automation solutions that not only boost efficiency but also empower your team. This sets you up for long-term success and continuous improvement.

Building An Implementation Strategy That Actually Works

The difference between a successful automation rollout and a costly mistake often comes down to your implementation strategy. I've seen this play out many times – meticulous planning, flexibility, and a good dose of practicality are key. Let's talk about building a strategy that actually delivers.

Creating Realistic Timelines (and Expecting the Unexpected)

Underestimating the time needed for implementation is a common pitfall. Vendors might promise quick deployments, but in my experience, it's rarely that simple. Unexpected delays, integration issues, and the learning curve are all factors. Always build in buffer time. It’s much better to overestimate than to play catch-up.

Managing Vendor Relationships (Without Getting Steamrolled)

Vendors are your partners, but remember, they're also selling you something. Find a balance between collaboration and critical thinking. Don’t be afraid to push back on unrealistic promises or overly complex solutions. I've seen companies get locked into contracts that weren't a good fit simply because they didn't ask enough questions upfront. For more on choosing the right partner, check out our guide on top automation consulting services.

Keeping Your Team Engaged (Even When Things Get Tough)

Implementation can be disruptive and stressful for your team. Keep them in the loop, involved, and motivated. Address their concerns, provide proper training, and celebrate the small victories. I once worked on a project where the team felt completely unprepared for the new system, which created resistance and slowed down the entire implementation. Open communication and consistent support are crucial.

Thorough Testing Before Going Live (Because Surprises Happen)

Thorough testing is essential. Don't just rely on the vendor; conduct your own tests in a real-world setting. Simulate real-world scenarios, including edge cases and potential problems. I've seen seemingly small bugs cause major system failures on launch day simply because they weren't caught during testing. Thorough testing can prevent many headaches.

Maintaining Operations During the Transition (Minimizing Disruption)

Implementation can be disruptive. Plan carefully to minimize the impact on your daily operations. Think about phased rollouts, parallel systems, and strong contingency plans. I've seen companies maintain almost perfect productivity during major system changes by carefully managing the transition. It takes planning, communication, and a lot of flexibility.

Building Internal Expertise (So You’re Not Always Dependent on Consultants)

While outside help can be valuable, focus on building internal expertise. This empowers your team to manage and maintain the systems after the consultants leave. Invest in training, mentoring, and knowledge sharing. I’ve seen companies become too reliant on vendors, leading to ongoing costs and a lack of internal ownership. Building internal expertise is a wise long-term investment.

Knowing When External Help Is Actually Worth It

External consultants offer specialized knowledge and experience, but they aren’t always necessary. Evaluate your internal capabilities and the project's complexity. Sometimes, a targeted consultation for a specific issue is more efficient than a full-blown implementation partnership. Understand your needs and choose your battles.

Preparing Your Team for Long-Term Success

Implementing new systems is just the beginning. Make sure your team is ready to use and maintain these systems over the long term. Develop clear documentation, establish ongoing training programs, and create support systems that empower your team to troubleshoot problems and improve performance. This fosters ownership and sets you up for lasting success. Following these strategies will help you create a solid foundation for successful automation implementation. Remember, it's a journey, not a destination. Be ready to adapt, learn, and continuously improve.

Managing Change Without Losing Your Best People

Let's face it, bringing supply chain automation into the mix changes the game for your team. Not everyone will be jumping for joy. Some folks might worry about their jobs, while others might resist learning new systems. I've chatted with tons of operations managers who've successfully guided their teams through these transitions, and they all emphasize one key thing: handle the change with care.

This image really highlights the human element of automation. Tech is vital, sure, but it's the people who make it all work. Managing this shift effectively is essential for winning in the long run.

Communicating Change Effectively

Don't just drop the news about changes; explain the why. Focus on what's in it for the team, not just the company's bottom line. Show them how automation can free them from tedious tasks, allowing them to tackle more interesting work. I know one manager who held regular Q&A sessions, and it made a huge difference in easing anxieties and getting everyone on board. Open communication builds trust and smooths the transition.

Addressing Concerns Head-On

Sweeping concerns under the rug? Bad idea. They'll only fester. Instead, create a safe space for people to voice their worries. Really listen to what they have to say, and give them honest, reassuring answers. For instance, one company retrained their warehouse staff to manage the new automated systems. They turned potential job losses into opportunities for growth. This proactive approach boosted morale and created a sense of shared purpose.

Identifying Training Needs That Go Beyond the Basics

Training shouldn't just be about clicking the right buttons. It's about empowering your team to actually manage the new systems. Figure out where the skill gaps are and create training programs that address them. Think about cross-training to build a more flexible and adaptable workforce. This makes sure everyone understands not only the how but also the why behind the automation.

Developing Effective Training Programs That Stick

Forget boring manuals and rushed presentations. Make training engaging and interactive. Use simulations, hands-on practice, and real-world examples. I worked with a company that created a “gamified” training program, and it significantly boosted engagement and knowledge retention. Making learning fun actually works!

Maintaining Morale During Transition

Change can be tough. Regular check-ins, team-building activities, and celebrating milestones can help keep spirits high. Recognize and reward those who jump in early. One company I worked with set up a mentorship program, pairing seasoned employees with those learning the new systems. It created a supportive environment and helped reduce anxiety.

Identifying and Leveraging Automation Champions

There will always be people who embrace change. Find these “champions” and give them the tools to help their colleagues. They can offer peer-to-peer support and drive adoption across the company. This kind of grassroots enthusiasm is way more effective than top-down directives.

Retaining Top Talent Who Might Be Nervous

Automation can create uncertainty about the future. Be transparent about career paths and opportunities within the automated environment. Invest in reskilling and upskilling programs. I've seen firsthand how companies have successfully kept their best employees by addressing their concerns and providing clear paths for professional development within the new, automated setting.

By focusing on these strategies, you can effectively manage the human side of automation, making sure your team not only adapts but thrives. This lets you fully benefit from your supply chain automation solutions while keeping a strong, motivated team.

Measuring Success And Continuously Improving Performance

Getting your supply chain automation solutions installed is just the beginning. The real journey starts after they're live. That's when you get to optimize, fine-tune, and constantly improve. It’s about way more than just watching throughput and accuracy. Those are definitely important, but there’s a bigger picture here. I've seen companies really excel at this optimization phase, and they all focus on metrics that actually predict long-term success, rather than just present performance.

Setting Realistic Expectations for ROI

Truthfully, automation isn't magic. It takes time to see a return on your investment. Your team will need to adapt, integrations may have hiccups, and there will always be unexpected bumps in the road. I've seen companies get disheartened because they expected instant results. Don't make that mistake. Set realistic expectations and acknowledge the small victories along the way. It's a marathon, not a sprint.

Tracking the KPIs That Predict Long-Term Success

Which metrics should you be focusing on? Order cycle time is key. How long does it take for an order to travel from placement to delivery? Automation should significantly shorten this. Inventory turnover is another critical one. Are your products flying off the shelves or collecting dust? Automation can help you optimize inventory levels, lowering carrying costs and boosting profits. And finally, keep a close watch on customer satisfaction. Are your customers happier with faster, more accurate deliveries? This is a true measure of long-term automation success. For even more ways to boost your supply chain’s performance, take a look at this resource: 7 Proven Ways to Improve Supply Chain Efficiency Fast. It’s got some valuable insights that complement what we’re talking about here.

Using Operational Data to Inform Decisions

Your automation systems are gold mines of data. Put that data to work! Analyze it to find bottlenecks, uncover areas for improvement, and validate future automation investments. I’ve worked with companies who’ve used this data to make smart changes to their warehouse layout, staffing, even their product assortment. This kind of data-driven decision making is powerful stuff.

Identifying Optimization Opportunities

Look for trends in your data. Are there certain times when performance dips? Are some products consistently causing delays? These patterns reveal opportunities for improvement. I once worked with a company that noticed a bottleneck in their shipping process during the afternoon shift. By adjusting staffing and tweaking their automated workflows, they solved the bottleneck and saw a big jump in throughput. This type of targeted optimization is way more effective than just making random changes.

Troubleshooting Performance Issues Before They Impact Operations

Don’t wait for small problems to turn into major fires. Use your data to spot potential issues before they impact your operations. Set up alerts for your key metrics. If order cycle time starts increasing or inventory turnover slows, you’ll know right away and can address it before your customers are affected. This proactive approach keeps your supply chain running smoothly and minimizes disruptions.

Continuously Improving Your Systems (Without Constant Disruption)

Constant improvement is vital, but it shouldn't mean constant chaos. Small, incremental changes are often more impactful than huge overhauls. I’ve seen companies fall into the trap of over-optimizing, constantly tweaking until they actually create instability. Sometimes, stability is more valuable than a tiny increase in efficiency. Find the sweet spot between optimizing and maintaining a stable system.

Avoiding the Trap of Over-Optimizing

Over-optimization creates fragile systems that are more likely to break down. I worked with a company that was obsessed with perfecting their automated picking system. They wrung every ounce of efficiency out of it, but the system became so complex that a minor glitch could bring the whole warehouse to a standstill. They learned a hard lesson: sometimes "good enough" really is good enough.

Focusing on Stability When It Matters Most

There are times when stability is more important than optimization. During peak seasons or product launches, for example, reliable performance should be your priority. Understand when to focus on stability and when to push for optimization. By applying these principles, your supply chain automation solutions will deliver real value and drive continuous improvement. Remember, it's an ongoing process. Be adaptable, keep learning, and always look for ways to improve.

Your Practical Path To Automation Success

So, you’re thinking about automating your supply chain. You’ve looked at your needs, explored the tech options, and even revamped your workflows. Great! Now, let's get down to brass tacks and actually implement these changes. Consider this your no-nonsense, practical guide, straight from the trenches – because, trust me, I’ve been there.

Building Your Automation Roadmap

Think of your automation journey as a series of manageable sprints, not a marathon. Clear milestones are key:

Phase 1: Perhaps you begin by automating your purchase order process. This is often a good starting point since it's a common pain point.

Phase 2: Once that's humming, maybe you integrate your Warehouse Management System (WMS) with some new Automated Guided Vehicles (AGVs). Now you're talking!

Phase 3: Later down the line, perhaps you implement AI-driven demand forecasting. This can be a game-changer for inventory management.

Each phase needs specific, measurable outcomes. Don’t just "set it and forget it." Regularly check in on your progress, tweak things as needed, and celebrate the wins – big or small. It’s important to keep the momentum going.

Realistic Timelines and Warning Signs

Truth be told, implementations rarely go exactly according to plan. Always build in some buffer time. Unexpected delays, integration hiccups, and the learning curve are all part of the process. I've seen too many companies rush things, only to have it blow up later. Be realistic with your timelines, and don’t be afraid to adjust them as you go. Need some broader perspectives on data analysis and what's possible with automation? Check out the visusly Homepage. It’s a great resource.

Also, be on the lookout for warning signs. These red flags can signal trouble:

Team Resistance: If your team is pushing back, it might be a sign of poor buy-in or a lack of proper training. Address this early!

Integration Issues: Are your systems playing nice together? If not, you might need to rethink your tech stack.

Unexpected Costs: Hidden costs can derail even the best-laid plans. Make sure you've accounted for everything. Check out Top Supply Chain Visibility Solutions for 2025 for more on optimizing your supply chain.

Catching these issues early can save you major headaches later on.

Building Long-Term Automation Capabilities

Automation isn't a one-and-done project. It’s an ongoing journey. You need to build internal expertise so you’re not always reliant on outside consultants. Invest in training and mentoring programs, and cultivate a culture of continuous improvement. Empower your team to own the systems and adapt to future changes. It’s like building a muscle – it takes consistent effort, but the payoff is worth it.

This practical approach will help you navigate the sometimes-tricky world of supply chain automation and set you up for lasting success. Remember, the technology should work for you, not the other way around.

Ready to transform your supply chain and unlock its full potential? Flow Genius offers expert automation consulting and implementation services tailored to your specific needs. We’ll guide you through every step, from strategic planning to seamless execution. Contact us today to learn how we can help you achieve scalable success through smart automation.

Comments