Top Cost Reduction Strategies for High-Value Sectors 2025

- Matthew Amann

- Sep 8, 2025

- 17 min read

In a competitive landscape, trimming expenses is a constant priority. However, true financial resilience isn't about arbitrary budget cuts; it's about strategic cost optimization that enhances efficiency without sacrificing quality or growth potential. Many businesses struggle with generic advice that fails to address the unique complexities of high-value sectors like technology, logistics, and energy. This guide moves beyond the obvious to provide a deep dive into nine powerful, actionable cost reduction strategies designed for immediate and lasting impact.

We will explore how leveraging automation, streamlining complex processes, and utilizing data analytics can create a robust framework for sustainable savings. This is not a theoretical exercise. You will find practical implementation steps for everything from lean manufacturing and strategic supplier management to inventory optimization and workforce planning. Each section is structured to provide clear, actionable insights that you can adapt to your specific operational needs, whether you are an infrastructure project manager, a logistics director, or a technology company leader. For businesses looking for specific actionable strategies, exploring proven ways to reduce software development costs can offer valuable insights into achieving sustainable savings in that critical area.

For organizations looking to transform their operations, consultancies like Flow Genius specialize in identifying efficiency gaps and implementing tailored automation blueprints that deliver immediate improvements in productivity and resource allocation. This guide will equip you with the practical insights needed to not just cut costs, but to build a more agile, profitable, and resilient enterprise for 2025 and beyond. By focusing on these sophisticated cost reduction strategies, you can build a leaner operation that is better prepared for market fluctuations and positioned for long-term growth.

1. Lean Manufacturing

Lean Manufacturing is a systematic approach to minimizing waste within a production system without sacrificing productivity. Originating from the Toyota Production System, this powerful cost reduction strategy focuses on maximizing customer value by eliminating non-value-added activities. The core principle is to produce exactly what is needed, when it is needed, with the minimum amount of materials, equipment, and labor.

This methodology identifies and targets the "Eight Wastes" of production: Defects, Overproduction, Waiting, Non-Utilized Talent, Transportation, Inventory, Motion, and Extra-Processing. By systematically addressing these areas, businesses can significantly streamline their operations, improve quality, and lower operational expenses.

Actionable Implementation Steps

Start Small: Begin with a pilot program in a single department or for a specific product line. This allows you to refine your approach and demonstrate success before a full-scale rollout.

Engage Frontline Workers: Your employees on the production floor are the experts in their daily tasks. Involve them in identifying sources of waste and brainstorming improvement opportunities.

Use Visual Management: Implement tools like Kanban boards or Andon lights to make workflow, progress, and problems visible to everyone. This transparency fosters accountability and enables rapid problem-solving.

Real-World Success Stories

The impact of lean principles is well-documented across industries. Toyota, the pioneer of this system, famously reduced its production costs by 30% and slashed inventory by 75%. Aerospace giant Boeing applied lean manufacturing to cut the production time for its 787 Dreamliner by 50%. These examples highlight how focusing on waste elimination directly translates into substantial financial gains and competitive advantages.

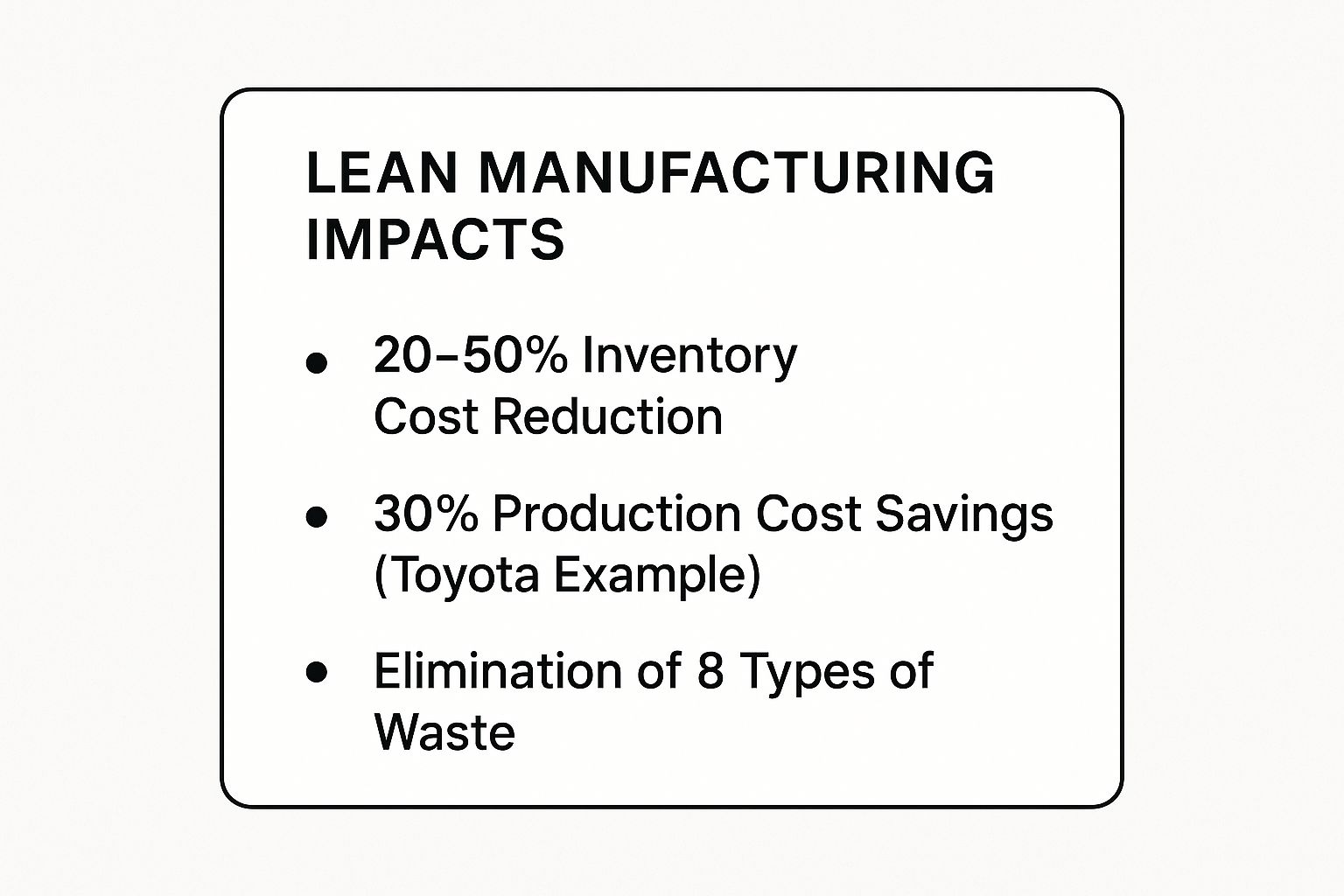

To illustrate the potential impact of this strategy, the following infographic summarizes key results from successful lean implementations.

As the data shows, adopting lean principles can lead to dramatic reductions in both inventory and overall production costs by systematically targeting specific types of operational waste. This makes it one of the most effective cost reduction strategies for any organization involved in production or complex service delivery.

2. Outsourcing Non-Core Activities

Outsourcing Non-Core Activities is a strategic business practice that involves contracting out specific business functions or processes to external, third-party providers. This approach allows a company to focus its internal resources on its primary competencies, those activities that create the most value and competitive differentiation. By delegating tasks like IT support, human resources, accounting, or customer service, businesses can access specialized expertise and advanced technologies without the high cost of in-house development.

This powerful cost reduction strategy works by converting fixed overhead costs into variable costs, providing greater operational flexibility and access to economies of scale. Instead of bearing the full expense of salaries, benefits, and infrastructure for non-essential departments, a company pays a service provider, often at a lower rate due to the provider's specialization and efficiency. This not only reduces direct expenses but also frees up capital for investment in core business growth.

Actionable Implementation Steps

Conduct Thorough Due Diligence: Start by meticulously vetting potential vendors. Evaluate their industry reputation, financial stability, technological capabilities, and security protocols to ensure they are a reliable and competent partner.

Establish Clear Service Level Agreements (SLAs): Define your expectations in a detailed SLA. This document should clearly outline performance metrics, responsibilities, reporting frequency, and penalties for non-compliance, leaving no room for ambiguity. For non-core tasks that don't require in-house expertise, leveraging virtual assistants can be a highly cost-effective outsourcing strategy.

Start with Non-Critical Functions: Test the outsourcing relationship by beginning with a low-risk, non-critical process. This pilot approach allows you to assess the vendor's performance and refine communication and workflows before entrusting them with more vital functions.

Real-World Success Stories

The benefits of strategic outsourcing are demonstrated by some of the world's largest corporations. IBM, a pioneer in business process outsourcing, reportedly saved $4 billion annually by delegating significant portions of its IT infrastructure management. Similarly, Procter & Gamble achieved a 30% reduction in IT costs through a comprehensive outsourcing partnership. Even American Express saw a 25% cost reduction after outsourcing its HR functions. These cases prove that when executed correctly, outsourcing is a formidable tool for achieving substantial financial savings and operational efficiency.

3. Strategic Supplier Management

Strategic Supplier Management is a proactive approach that transforms procurement from a transactional function into a powerful engine for value creation. Instead of focusing solely on the lowest price, this strategy involves building long-term, collaborative partnerships with key suppliers to optimize costs, mitigate risks, and drive innovation. The core idea is that a company’s performance is directly linked to the performance of its supply chain, making supplier relationships a critical competitive asset.

This methodology goes beyond simple vendor negotiation by focusing on mutual growth, performance management, and joint cost-reduction initiatives. By aligning suppliers with your business objectives, you can unlock efficiencies in areas like inventory management, quality control, and product development. This collaborative model creates a resilient supply chain that adapts to market changes and delivers sustained financial benefits.

Actionable Implementation Steps

Implement Supplier Scorecards: Develop and use objective scorecards to track key performance indicators (KPIs) such as on-time delivery, quality, and cost competitiveness. This data provides a clear basis for performance discussions and improvement plans.

Establish Joint Cost Reduction Targets: Work collaboratively with strategic suppliers to identify waste and inefficiencies in the shared value chain. Set mutual goals for cost reduction and agree on a framework for sharing the resulting savings.

Invest in Supplier Development: Provide training, resources, and technical support to help your key suppliers improve their capabilities. A stronger supplier is a more reliable and cost-effective partner. For a deeper look into this area, explore these vendor management best practices.

Real-World Success Stories

The power of strategic supplier management is evident in the success of global industry leaders. Walmart’s renowned vendor partnership program is credited with reducing its procurement costs by billions, enabling its "Everyday Low Prices" strategy. Similarly, Honda’s supplier development initiatives have famously improved component quality by over 50% while simultaneously reducing costs.

Apple’s tight-knit relationships with its component suppliers allow it to optimize production costs while maintaining premium quality standards, a key factor in its high-profit-margin products. These examples demonstrate that treating suppliers as partners is one of the most effective cost reduction strategies for achieving long-term, sustainable savings and a distinct competitive advantage.

4. Automation and Process Digitization

Automation and Process Digitization involves implementing technology to handle manual, repetitive processes, thereby reducing human intervention and boosting operational efficiency. This powerful cost reduction strategy encompasses everything from robotic process automation (RPA) for administrative tasks to sophisticated artificial intelligence for complex data analysis. By digitizing workflows and automating tasks, businesses can eliminate human error, accelerate operations, and free up employees to focus on high-value activities that drive growth.

This approach targets inefficiencies directly at their source. Instead of paying for hours of manual data entry, document processing, or system updates, companies invest in software that performs these tasks instantly and accurately. For example, learning how to automate repetitive tasks to save time is a direct path to boosting productivity and cutting operational expenses, making this one of the most impactful cost reduction strategies available today.

Actionable Implementation Steps

Start with Simple, Rule-Based Processes: Begin by identifying high-volume, low-complexity tasks like data entry, invoice processing, or generating standard reports. These quick wins provide a clear ROI and build momentum for more complex projects.

Calculate ROI Carefully: When evaluating automation tools, consider the total cost of ownership, including initial setup, licensing, and ongoing maintenance. Compare this against the projected savings in labor costs, error reduction, and increased productivity.

Provide Comprehensive Training: Effective change management is crucial. Ensure employees understand how automation will augment their roles, not replace them. Provide thorough training to help them work alongside new digital systems and manage the automated processes.

Real-World Success Stories

The transformative power of automation is evident across major industries. JP Morgan Chase implemented its COIN system, which uses machine learning to analyze legal documents, saving an estimated 360,000 hours of manual work annually. Similarly, Amazon's extensive use of robotics in its fulfillment centers has cut operational costs by over 20% while speeding up delivery times. Shipping giant Maersk's digitization of its container booking and documentation process reduced processing times by an incredible 90%.

These examples demonstrate that strategic automation is not just about incremental improvements; it’s a fundamental shift that creates a leaner, more agile, and highly competitive organization. To explore this topic further, discover the key benefits of business automation in 2025. This makes automation a cornerstone of modern cost reduction strategies.

5. Energy Efficiency and Sustainability Programs

Energy Efficiency and Sustainability Programs are comprehensive initiatives designed to minimize a company's environmental footprint while unlocking substantial financial savings. This approach goes beyond simply turning off lights; it involves a strategic re-evaluation of how resources like energy, water, and raw materials are consumed and managed across all operations. The core principle is that reducing waste and improving resource efficiency directly correlates with lower operational costs and enhanced brand reputation.

These programs encompass a wide range of activities, from conducting detailed energy audits and upgrading to energy-efficient equipment to adopting renewable energy sources and implementing robust waste reduction protocols. By systematically targeting inefficiencies, businesses can achieve significant cost reduction, mitigate risks associated with fluctuating energy prices, and meet growing consumer demand for environmentally responsible practices.

Actionable Implementation Steps

Conduct Comprehensive Energy Audits: Start by performing a thorough audit of your facilities to identify the most significant areas of energy consumption and waste. This data provides a clear roadmap for prioritizing high-impact improvements.

Implement an Energy Management System (EMS): Use technology to gain real-time visibility into your energy usage. An EMS allows for continuous monitoring, helping you track progress against targets and quickly identify anomalies or new savings opportunities.

Leverage Financial Incentives: Research and apply for utility rebates, tax credits, and government grants designed to support energy efficiency upgrades and renewable energy adoption. These incentives can significantly lower the upfront investment costs.

Engage Employees: Foster a culture of conservation by launching awareness programs. Educate staff on the importance of sustainability and empower them to contribute ideas for reducing waste in their daily routines.

Real-World Success Stories

The financial benefits of robust sustainability programs are proven across major industries. Retail giant Walmart, for example, reportedly saved over $1 billion annually through its comprehensive energy efficiency initiatives, including upgrading to LED lighting and optimizing its trucking fleet. Similarly, Interface Inc., a pioneer in sustainable manufacturing, reduced its energy intensity per unit of production by 96%, demonstrating that profound environmental goals can align with strong business growth.

These examples showcase how investing in sustainability is not just an ethical choice but also a powerful and effective cost reduction strategy. By systematically reducing consumption and waste, companies can secure long-term financial resilience and build a competitive advantage in an increasingly eco-conscious market.

6. Shared Services Centers

Shared Services Centers (SSCs) are a powerful cost reduction strategy that involves consolidating and centralizing common business functions, such as HR, Finance, and IT, from multiple business units into a single, specialized hub. This approach eliminates redundant roles and systems, standardizes processes, and leverages economies of scale to drive significant operational efficiencies. By centralizing these back-office tasks, businesses can improve service quality, enforce best practices, and free up individual departments to focus on core, value-generating activities.

This model transforms transactional functions into a strategic asset. Instead of each location or division managing its own administrative overhead, the SSC acts as an internal service provider, delivering consistent and high-quality support across the entire organization. This centralization not only reduces direct costs associated with staffing and infrastructure but also enhances control, improves data accuracy, and supports faster decision-making through unified reporting and analytics.

Actionable Implementation Steps

Start with Mature Processes: Begin by centralizing functions that are highly transactional and well-defined, such as accounts payable or payroll. These areas offer clear opportunities for standardization and quick wins.

Establish Clear Governance: Develop formal Service Level Agreements (SLAs) that define performance metrics, service quality, and responsibilities. A clear governance structure is crucial for managing expectations and ensuring accountability.

Invest in Enabling Technology: Implement a robust technology platform, like an Enterprise Resource Planning (ERP) system or specialized service desk software, to automate workflows, manage requests, and enable efficient service delivery.

Real-World Success Stories

The impact of shared services is evident across global enterprises. General Electric famously reduced its finance costs by over $500 million by consolidating its financial operations. Similarly, Procter & Gamble's Global Business Services unit achieved savings of more than $900 million over five years by centralizing its administrative functions. Even in capital-intensive industries, the model proves effective; Shell reduced operational costs by 40% through its shared services network while simultaneously improving service quality.

These cases demonstrate that creating Shared Services Centers is more than a simple consolidation exercise. It is a strategic transformation that, when executed correctly, unlocks substantial financial benefits and operational excellence, making it a cornerstone among effective cost reduction strategies.

7. Inventory Optimization

Inventory Optimization is a data-driven approach to minimize inventory carrying costs while ensuring high service levels. This strategy involves using advanced analytics, demand forecasting, and sophisticated management techniques to strike the perfect balance between the cost of holding inventory and the risk of stockouts. The goal is to have the right amount of stock, in the right place, at the right time, avoiding both expensive overstock and damaging shortages.

By analyzing historical sales data, market trends, and supply chain lead times, businesses can make more accurate predictions about future demand. This allows for a significant reduction in safety stock and prevents capital from being tied up in slow-moving or obsolete products. Effective inventory optimization is a critical component of modern cost reduction strategies, turning a company's supply chain from a cost center into a competitive advantage.

Actionable Implementation Steps

Implement ABC Analysis: Categorize your inventory items based on their value. "A" items are high-value, "B" are medium-value, and "C" are low-value. This allows you to focus your management efforts on the items that have the biggest financial impact.

Leverage Technology: Utilize statistical forecasting methods and specialized software to improve demand planning accuracy. Modern tools can automate much of this process. Explore options for the best inventory management software for your small business on flowgenius.ai.

Establish VMI Programs: Collaborate with key suppliers to create Vendor-Managed Inventory (VMI) programs. In a VMI system, the supplier takes responsibility for maintaining agreed-upon inventory levels at your location, reducing your administrative burden and improving stock availability.

Real-World Success Stories

The power of inventory optimization is evident across various industries. Dell's revolutionary build-to-order model minimized finished goods inventory, allowing it to operate with exceptional capital efficiency. Similarly, Zara’s fast-fashion model relies on tight inventory control and rapid turnover, which helped reduce its inventory levels by 50% compared to industry averages. More recently, Amazon has used predictive analytics to position products in fulfillment centers before they are even ordered, reducing both shipping times and inventory costs by billions. These examples prove that optimizing inventory is a direct path to a leaner, more profitable operation.

8. Workforce Optimization

Workforce Optimization is a strategic approach to managing human capital that aims to align labor resources with business objectives, enhancing productivity while controlling costs. This goes beyond simple scheduling; it involves a holistic view of the entire employee lifecycle, from hiring and training to performance management and retention. The core principle is to have the right people with the right skills in the right roles at the right time.

This powerful cost reduction strategy focuses on maximizing the value of your workforce by improving efficiency, boosting engagement, and reducing labor-related expenses like overtime and turnover. By leveraging data analytics and advanced planning tools, businesses can anticipate staffing needs, identify skill gaps, and deploy employees more effectively. This ensures that every labor dollar spent contributes directly to operational goals and customer satisfaction.

Actionable Implementation Steps

Implement Workforce Analytics: Use HR data to identify patterns in productivity, absenteeism, and turnover. These insights will reveal key opportunities for improvement and help forecast future staffing requirements.

Develop Flexible Staffing Models: Move beyond traditional fixed schedules. Implement flexible work arrangements, cross-training programs, and on-demand staffing to match labor capacity precisely with fluctuating business demand.

Invest in Skills Development: A well-trained workforce is a productive one. Create targeted training and upskilling programs to close skill gaps, improve performance, and prepare employees for future roles, reducing the need for costly external hires.

Real-World Success Stories

The benefits of workforce optimization are evident across various industries. UPS famously saved an estimated $600 million annually by using route optimization technology, a key component of workforce management that maximizes driver efficiency. Similarly, Accenture improved its talent utilization by 25% after adopting a skills-based model, ensuring its consultants were deployed on projects that best matched their expertise. Even Starbucks enhanced its labor efficiency by 20% through a cross-training program that allowed for more flexible staff deployment during peak hours.

These examples demonstrate that strategic workforce management is not just about cutting headcount; it's about making your team more effective and engaged. By focusing on efficiency and skill alignment, organizations can achieve significant cost savings while simultaneously improving service quality and employee morale, making it a crucial component of any modern cost reduction strategy.

9. Value Engineering and Design-to-Cost

Value Engineering and Design-to-Cost is a systematic, function-oriented methodology for reducing expenses by analyzing the components and processes of a product or service. This powerful cost reduction strategy aims to eliminate unnecessary costs while maintaining or even enhancing functionality and quality. It scrutinizes every element of design and production to ensure it delivers maximum value at the lowest possible lifecycle cost.

This approach challenges the assumption that existing designs are optimal, forcing a re-evaluation of materials, processes, and features from a purely functional perspective. By integrating cost as a primary design parameter from the outset (Design-to-Cost), organizations can prevent over-engineering and embed efficiency directly into the product's DNA, moving beyond simple cost-cutting to intelligent value optimization.

Actionable Implementation Steps

Form Cross-Functional Teams: Assemble a dedicated team that includes members from design, engineering, manufacturing, procurement, and marketing. This diversity of expertise ensures that all aspects of a product's lifecycle are considered during the value analysis.

Challenge Every Component: For each part or process step, ask fundamental questions like, "What function does this perform?" and "Can this function be achieved more cost-effectively?" This breaks down complex products into manageable functional units for optimization.

Standardize and Simplify: Whenever possible, use standardized components and materials that are readily available and less expensive. Simplifying designs by reducing part counts not only lowers material costs but also streamlines assembly and reduces potential points of failure.

Real-World Success Stories

The impact of value engineering is evident across high-value sectors. Aerospace giant Boeing famously applied these principles to its 787 Dreamliner, successfully reducing manufacturing costs by an estimated 20%. Similarly, Ford's value engineering program was credited with saving the company over $1.25 billion in a single year by optimizing vehicle components.

In the consumer electronics space, Samsung utilized a Design-to-Cost approach to reduce smartphone component costs by as much as 30%, enhancing its competitive edge in a crowded market. These examples demonstrate that by systematically analyzing function and cost, businesses can achieve significant savings without compromising the quality or performance that customers demand, making it a cornerstone of effective cost reduction strategies.

Cost Reduction Strategies Comparison Matrix

Strategy | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Lean Manufacturing | High – cultural change and ongoing commitment | Moderate to High – training and time | Significant cost reduction, improved quality, lead time | Manufacturing and operations seeking waste elimination | Waste elimination, continuous improvement, employee engagement |

Outsourcing Non-Core Activities | Moderate – vendor selection and contract management | Variable – depends on scope and partners | Operational cost savings, access to specialized skills | Non-core functions to reduce costs and increase focus | Cost reduction, scalability, access to expertise |

Strategic Supplier Management | Moderate to High – relationship and performance mgmt | Moderate – time and collaboration effort | Cost savings, improved quality, supply chain risk reduction | Companies aiming for long-term supplier collaboration | Supplier innovation, cost control, risk management |

Automation and Process Digitization | High – technology integration and change management | High – investment in technology and training | Labor cost reduction, accuracy, speed, 24/7 operation | Processes with repetitive/manual tasks requiring efficiency | Cost savings, accuracy, scalability, data-driven insights |

Energy Efficiency and Sustainability Programs | Moderate – requires capital investment and expertise | High – upfront costs for upgrades | Utility cost reduction, brand enhancement, long-term savings | Organizations targeting sustainability and cost control | Cost savings, environmental benefits, incentives |

Shared Services Centers | High – centralization and change management | Moderate to High – technology and governance | Operational cost reduction, process standardization | Multi-unit businesses consolidating support functions | Cost reduction, standardization, career development |

Inventory Optimization | Moderate – advanced analytics and demand planning | Moderate – technology and skilled personnel | Lower inventory costs, improved cash flow and service | Retail, manufacturing, and distribution with inventory challenges | Cost savings, demand visibility, reduced waste |

Workforce Optimization | High – planning, training, and performance systems | Moderate – HR technology and training | Labor cost reduction, improved productivity and retention | Organizations managing diverse or flexible workforce | Productivity, flexibility, employee engagement |

Value Engineering and Design-to-Cost | High – requires cross-functional collaboration | Moderate – design team time and expertise | Product cost reduction while maintaining quality | Product development focusing on cost and functionality | Cost savings, improved functionality, competitive edge |

Turning Strategy into Sustainable Savings

The journey through these nine distinct yet interconnected cost reduction strategies reveals a powerful, unifying theme: sustainable financial health is not achieved through drastic, one-time cuts, but through a systematic and intelligent redesign of how a business operates. From the shop floor efficiencies of Lean Manufacturing to the strategic foresight of Value Engineering, each approach offers a pathway to not only reduce expenses but also to build a more resilient, competitive, and agile organization. We have moved beyond the outdated notion of cost-cutting as a reactive measure and repositioned it as a proactive strategy for long-term value creation. The core principle is clear: efficiency is the new currency, and optimization is the engine of modern business growth.

The strategies detailed in this article, such as Strategic Supplier Management and Workforce Optimization, are not isolated initiatives. Instead, they are components of a larger, integrated system. True transformation occurs when these elements work in concert. Imagine a logistics company that combines Inventory Optimization with advanced Automation and Process Digitization. It doesn't just reduce warehousing costs; it creates a predictive, self-correcting supply chain that anticipates demand, minimizes waste, and enhances customer satisfaction. Similarly, an energy firm implementing robust Energy Efficiency Programs alongside a Shared Services model for its administrative functions can reallocate significant capital towards core innovation and exploration.

The Central Role of Technology and Data

A critical thread weaving through nearly every strategy is the indispensable role of technology, particularly automation and data analytics. In today's digital-first landscape, manual processes are not just inefficient; they are a liability. They introduce human error, create bottlenecks, and obscure valuable operational insights.

Automation: Platforms like Zapier, Make.com, and n8n are no longer just tools for tech companies. A roofing contractor can automate lead follow-ups and scheduling, freeing up time for project management. A real estate broker can create sophisticated CRM workflows that nurture client relationships without constant manual input. This is the essence of modern cost reduction: investing in systems that work for you, amplifying your team's capacity and reducing the cost associated with repetitive, low-value tasks.

Data-Driven Decisions: The shift from intuition-based to data-driven decision-making is perhaps the most significant competitive advantage a company can secure. Effective cost reduction is impossible without clear, accurate metrics. By analyzing operational data, businesses can pinpoint the precise sources of inefficiency, validate the impact of new initiatives, and forecast future trends with greater accuracy. This is where a data advisory service becomes invaluable, helping to translate raw numbers into a coherent, actionable strategy.

From Theory to Action: Your Next Steps

Reading about these strategies is the first step, but implementation is what separates market leaders from the rest. The path forward requires a deliberate and structured approach. Begin not by trying to implement everything at once, but by identifying the area with the most significant potential for impact within your organization.

Conduct a Diagnostic Audit: Start with a thorough review of your current processes. Where are the most significant bottlenecks? Which activities consume the most manual hours? Where is budget leakage most apparent?

Prioritize an Initiative: Based on your audit, select one or two high-impact cost reduction strategies to pilot. For a commercial cleaning business, this might be automating scheduling and supply management. For a technology company, it could be integrating disparate software systems to create a single source of truth.

Define Clear Metrics for Success: How will you measure the success of your pilot program? Be specific. Aim for goals like "reduce administrative processing time by 30%" or "decrease energy consumption by 15% within six months."

Embrace a Culture of Continuous Improvement: Finally, and most importantly, treat cost optimization as an ongoing discipline, not a one-off project. Foster a culture where employees are empowered to identify inefficiencies and suggest improvements. The most sustainable savings come from the collective, continuous effort of an engaged and efficiency-minded team.

By adopting this mindset, you transform cost reduction from a painful necessity into a strategic advantage, creating a leaner, more innovative, and profoundly more profitable enterprise poised for future success.

Ready to move from strategy to implementation? The experts at Flow Genius specialize in designing and deploying the smart automation and data-driven workflows discussed throughout this article. Let us help you build the efficient, cost-effective operational backbone your business needs to thrive. Discover how Flow Genius can transform your processes today.