Automating Inventory Management for Your Business

- Matthew Amann

- Jul 19, 2025

- 16 min read

Automating your inventory management is all about using technology to handle the tedious work of tracking stock, processing orders, and reordering products. The goal is to move away from manual spreadsheets and endless physical counts, replacing them with a system that provides real-time, accurate data. This shift is no longer a luxury; it's a critical step to prevent costly mistakes like stockouts and overstocking, ultimately protecting your bottom line.

Why Automating Your Inventory Is a Modern Necessity

Let's be real—relying on manual inventory tracking in today's market is a high-stakes gamble. With unpredictable supply chains and customers who expect immediate availability, a single data entry error in a spreadsheet can set off a disastrous chain reaction. These small mistakes have a nasty habit of snowballing into major financial hits and a tarnished brand reputation.

The Real Costs of Manual Tracking

The most obvious headaches from manual systems are stockouts and overstocking. Running out of a popular item means more than just one lost sale; it sends a frustrated customer straight to your competitor, and they might not come back. On the flip side, overstocking ties up your cash in products that are just collecting dust. This "dead inventory" eats up precious warehouse space and often ends up as a complete write-off.

But the problems run deeper than just what's on the shelves. Think about these hidden costs:

Wasted Labor: Your team is sinking countless hours into tedious physical counts and mind-numbing data entry. Imagine if they could spend that time on high-impact activities like improving customer service or negotiating better deals with suppliers.

Inaccurate Forecasting: Without solid, real-time data, you're essentially guessing what your customers will want next. This kind of guesswork leads directly to poor purchasing decisions and missed opportunities for growth.

Slow Reactions: When a supply chain issue pops up—and it will—a manual system is simply too sluggish to adapt. You're left exposed to sudden shortages or painful price increases that you could have otherwise avoided.

Automating inventory isn't just about being more efficient. It's a strategic move that builds resilience into your business. It gives you the agility to react to market changes, meet customer demand with precision, and make decisions based on data, not gut feelings.

The market's clear shift toward automation proves this point. Valued at $2.31 billion in 2024, the global inventory management software market is expected to more than double, reaching $4.79 billion by 2032. This incredible growth is fueled by businesses finally ditching outdated methods for smarter, integrated platforms.

To get a better sense of how automation impacts the bigger picture, you can find great resources on AI automation for smarter business growth that explore how other companies are making these tools work for them.

Setting the Stage for Successful Automation

It’s tempting to jump straight into powerful automation tools, but that's a classic rookie mistake. I’ve seen it happen too many times—enthusiasm quickly turns into frustration because the groundwork wasn't laid first. Think of this initial phase as preparing the foundation before you build the house.

Automating a messy, inefficient process just means you’ll make mistakes faster. It's the old "garbage in, garbage out" principle, and it can turn a promising automation project into a costly failure. So, before you touch Zapier or write a single line of code, you need to take a hard look at how you’re doing things right now.

Map Your Current Inventory Workflow

Your first job is to become an expert on your own inventory’s journey. You need to trace every single step a product takes, from the moment you cut a purchase order to the second it lands in a customer's hands. This isn't about the ideal process you have in your head; it’s about what actually happens on the warehouse floor every day.

Get into the weeds with this. Talk to your team and ask the tough questions:

Receiving: How are new shipments really handled? Who's counting the items, checking for damage, and where is that info being logged? Is it on a clipboard? A spreadsheet?

Put-Away: What's the exact path an item takes from the receiving dock to its home on the shelf? Is its location recorded, and is that record accurate?

Sales & Fulfillment: When an order drops in from Shopify, Amazon, or your POS system, what happens next? Detail the real-world process of finding it, picking it, packing it, and shipping it. Critically, how is the stock count updated after it’s gone?

Returns: What’s the procedure for a returned item? How do you inspect it and decide if it goes back into sellable inventory? How does that get reflected in your system?

Going through this exercise almost always reveals hidden bottlenecks and tedious manual work. You might find your team spends 90 minutes every morning just reconciling sales from different channels against a master spreadsheet—a perfect task to automate. This entire exercise is about understanding what you have, a core principle detailed in any good guide to business process automation.

Standardize Your Product Data

With a clear map of your workflow, the next mission is to clean up your data. Inconsistent data is the silent killer of any automation effort. Your new, automated system will need one, and only one, way to identify every single product you sell.

This is where you have to be meticulous. You can't have "Blue T-Shirt - Large" in one system and "Tee-BLU-L" in another and expect things to run smoothly. They won't.

Key Data Points to Standardize:

Data Element | Standardization Goal | Common Problem to Fix |

|---|---|---|

SKUs | One unique, permanent identifier for each product variant. | Relying on supplier part numbers, which can change without warning. |

Product Names | A consistent naming convention across every sales channel. | "Men's Classic Tee" vs. "Classic T-Shirt (M)" for the same item. |

Supplier Info | Standardized names and details for every vendor. | Listing "ACME Corp" and "Acme Corporation" as two separate suppliers. |

Units of Measure | Clearly defining how you count (e.g., "Each," "Case," "Pack"). | Receiving a case of 12 but logging it as 1 item, destroying your counts. |

A clean, standardized dataset is the single most valuable asset you have when starting an automation project. The hours you spend cleaning up SKUs now will save you weeks of troubleshooting frustrating errors down the road.

Think about it like this: a barcode scanner doesn't know what a "best-seller" is. It just reads a code. If that code isn't applied and tracked consistently, the whole system falls apart. This isn’t a one-and-done task, either. Regular audits—even just spot-checking a few bins against your master list—are essential for keeping your data clean over the long haul. Get this right, and you'll build an efficient machine, not a high-speed engine of chaos.

Choosing the Right Automation Toolkit for Your Business

Alright, you've mapped your workflows and cleaned up your data. Now comes the exciting part: picking the tech that will actually do the work for you. This is a big decision. The right tools feel like adding a new, brilliant team member, while the wrong ones can just create more headaches.

There's no magic bullet here. The "best" solution is the one that fits your budget, your team's comfort with technology, and your company's ambition. Let’s walk through the options, from getting started quickly to building a system that can scale with you.

Getting Started with No-Code Automation Platforms

For most businesses just dipping their toes into automation, no-code platforms are the way to go. Think of tools like Zapier, Make, or n8n as the universal translators for your apps. They connect the software you already use—your e-commerce store, your spreadsheet, your team chat—without you needing to write a single line of code.

It's all visual. You're basically setting up a digital chain reaction. When one thing happens (the "trigger"), it kicks off a series of other tasks you've laid out.

Here’s a classic e-commerce setup I see all the time:

Trigger: A customer's payment goes through on Shopify.

Action 1: Instantly, a new row appears in a Google Sheet, logging the order details.

Action 2: The system then finds the products that were sold and subtracts the quantity from a master inventory tab in that same sheet.

Action 3: A notification pings your fulfillment team's Slack channel with the new order.

Just like that, you've eliminated a ton of manual copy-pasting, cut down on errors, and made sure everyone is on the same page. The real power is in their massive libraries of pre-built connections. You can link just about anything.

The biggest win with no-code tools is how fast you can get up and running. I've seen teams build and launch their first critical inventory workflow in a single afternoon. The time saved and mistakes avoided deliver a return on investment almost immediately.

Graduating to Custom Scripts

As your business gets more complex, you'll eventually hit a wall with what the no-code platforms can do. You might have a weird, specific need that a simple trigger-action recipe can't solve. This is where custom scripting, usually with a language like Python, becomes your best friend.

Don't let the word "scripting" scare you. You don't have to become a developer overnight. Many businesses bring in a freelance developer for small, targeted projects. A custom script gives you total freedom to build something that fits your operation perfectly.

A few real-world examples I've helped build:

Smarter Low-Stock Alerts: We set up a Python script to run every hour. It connects directly to the inventory database, checks stock levels against dynamic thresholds (e.g., selling velocity), and emails a prioritized list of SKUs to the purchasing manager.

Automated Purchase Orders: Taking it a step further, another script identifies low-stock items and then automatically generates a purchase order PDF, pre-filled with the right supplier info, and emails it directly for approval.

Multi-Channel Syncing: If you're selling across Shopify, Amazon, and a physical store, a custom script can be the central brain. It pulls sales from all channels, updates a master inventory count, and then pushes the correct stock level back out to each platform to kill overselling for good.

While it's a bigger investment in time and money, scripting unlocks a level of precision that no-code tools just can't offer. It's the natural next move when your processes are too unique for a pre-packaged solution. Looking into the https://www.flowgenius.ai/post/8-key-business-process-automation-benefits-for-2025 will show you just how powerful these tailored solutions can be.

Investing in Dedicated Inventory Systems

Eventually, if you're managing a ton of inventory, multiple warehouses, or a complex global supply chain, the combination of no-code tools and scripts will start to feel like patchwork. This is when you need to bring in the heavy hitters: a dedicated Inventory Management System (IMS) or a full Warehouse Management System (WMS).

These are not just tools; they are comprehensive platforms built specifically for inventory. They become the absolute source of truth for your entire operation. An IMS handles tracking, ordering, and sales data, while a WMS adds another layer for managing the physical warehouse—things like bin locations, optimized picking routes, and staff assignments.

These systems are designed to plug directly into barcode scanners, shipping carriers, and accounting software, creating a seamless, unified operation. They are the biggest investment, but for a large-scale business, the control and efficiency they provide are game-changing. To find what might work for your setup, check out these top Shopify apps for real-time inventory sync that can serve as a powerful foundation.

Automation Tool Comparison

To help you decide which path is right for you, here’s a quick breakdown of the three approaches.

Automation Approach | Typical Cost | Required Skill Level | Best For |

|---|---|---|---|

No-Code Platforms | Low (Free to ~$100/mo) | Beginner (Visual, drag-and-drop) | Startups and SMBs needing quick, simple integrations. |

Custom Scripts | Moderate (Developer costs) | Intermediate (Coding knowledge) | Growing businesses with unique workflow needs. |

Dedicated IMS/WMS | High (Thousands+) | Varies (Vendor support) | Large-scale operations with complex logistics. |

Ultimately, this isn't about jumping to the most expensive solution. It's about honestly assessing where you are now and choosing the tool that will solve today's problems while giving you room to grow.

Putting Theory Into Practice: Your First Automated Inventory Workflows

Alright, this is where the rubber meets the road. You’ve done the hard work of cleaning up your data and figuring out exactly what you need your system to do. Now, it's time to actually build the automated workflows that will save you countless hours and prevent those costly, forehead-slapping mistakes.

Let's walk through three real-world examples, starting with a simple but powerful setup and working our way up to a more complex one. The whole idea is to create a chain reaction. A single event—like a sale—kicks off a series of tasks that update everything in real time. It's this immediate feedback loop that makes automation so effective.

Workflow 1: Your First Zapier Automation

For our first workflow, we’ll use a fantastic no-code tool called **Zapier**. Our goal is straightforward but incredibly useful: when a new sale comes through on Shopify, we’ll automatically update our master inventory list in a Google Sheet. This one simple automation completely removes the need for manual data entry and gives you an up-to-the-minute view of your stock.

Here’s how the logic works in Zapier:

The Trigger: It all starts the moment a "New Paid Order" is logged in your **Shopify** store. This is the event that sets everything else in motion.

The First Action (Lookup): Zapier then grabs the product details from that order. It uses a "Lookup Spreadsheet Row" action to scan your master Google Sheet, searching for the SKU that matches the item just sold.

The Second Action (Update): Once it finds the right product row, it performs an "Update Spreadsheet Row" action. This is where you use a tiny bit of Zapier's formula magic to take the current stock number and subtract the quantity sold in the order.

This simple, three-part "Zap" ensures your Google Sheet is always the single source of truth for your inventory. The instant a sale happens, your stock count is adjusted. No one has to lift a finger.

Workflow 2: Automated Low-Stock Alerts

Now that you have live inventory data flowing, you can build on that foundation. One of the biggest headaches for any product-based business is not realizing a hot-seller is about to run out until it's too late. This next workflow creates an automatic alert system to give you a heads-up when stock levels dip below a certain point.

We can actually build this right on top of the Zap we just created. Here’s how:

Set Your Threshold: First, go into your Google Sheet and add a new column called "Reorder Point." This is the minimum quantity you feel comfortable having on hand. For a fast-moving t-shirt, that might be 20 units. For a niche accessory that sells slowly, it could be just 5.

Create a Filter: Back in Zapier, right after the step that updates your inventory, you’ll add a "Filter." This handy step simply checks if the "New Stock Quantity" is less than or equal to the "Reorder Point" for that specific product.

Trigger an Alert: If the filter's condition is true (meaning, stock is low!), the Zap moves on to its final action: sending a notification. This could be an email to your purchasing manager, a message to a #procurement channel in Slack, or even a new task in a project management tool like **Asana**.

The beauty here is that the system is proactive. You’re not reacting to a stockout anymore; you’re getting ahead of the problem. This simple alert can easily be the difference between a happy, returning customer and a sale you lose to a competitor.

This move toward instant data access is a massive industry shift. In fact, roughly 77% of retailers are aiming to have real-time inventory visibility by 2025, using automation and analytics to finally ditch their outdated, manual methods. You can learn more about how this is changing the game by reading up on the latest retail inventory management statistics.

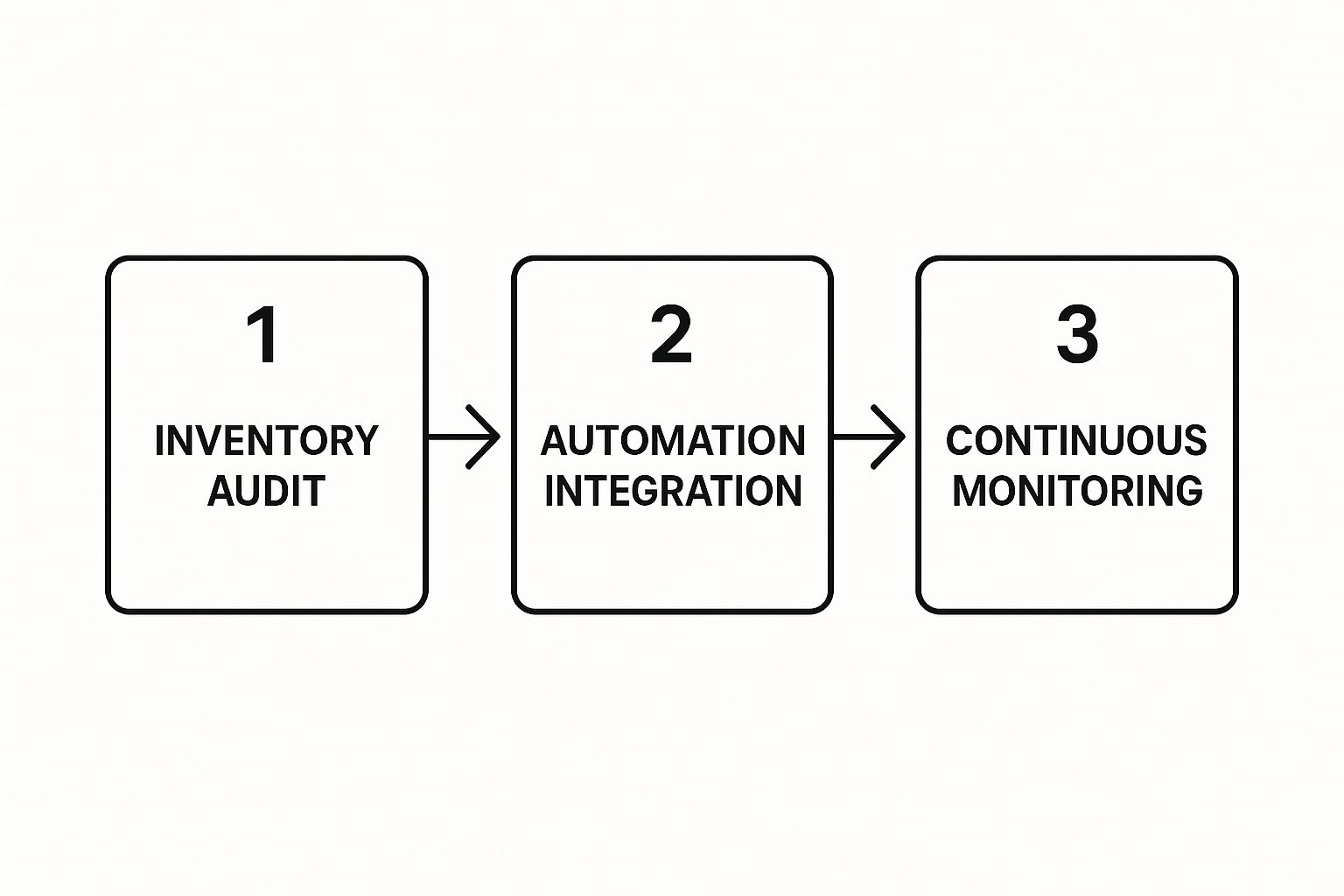

The process flow below shows how all these pieces—auditing your inventory, integrating automation, and constantly monitoring the results—fit together.

As you can see, successful automation isn't a "set it and forget it" project. It's a continuous cycle of refinement and improvement.

Workflow 3: Syncing Online and Physical POS Inventory

For anyone running both an e-commerce site and a brick-and-mortar store, keeping inventory in sync is a notorious nightmare. Selling your last widget in-store while your website still shows it as available is a recipe for customer frustration and cancelled orders.

This more advanced workflow tackles that problem head-on by syncing inventory between two different systems—for instance, Shopify for your online store and **Square** for your in-store POS. This usually requires something a bit more robust than Zapier, like a dedicated inventory management system (IMS) or even a custom script, because it needs to handle a two-way sync.

The Logic of a Two-Way Sync

Sale Location | Action | System Response |

|---|---|---|

In-Store (Square) | A product is sold at your physical location using the Square POS. | The automation detects the sale, deducts the quantity from a central IMS, and immediately pushes the new, lower stock count to your Shopify store. |

Online (Shopify) | The same product is sold on your website. | The automation detects the online sale, deducts the quantity from the IMS, and pushes the updated stock count back to your Square POS system. |

This setup effectively creates a central "brain" for all your stock. It doesn't matter where a sale happens; the master count is updated everywhere almost instantly.

How to Make It Happen:

Dedicated Apps: Check the app marketplaces for Shopify and Square. You'll often find third-party apps built specifically to connect inventory between the two platforms.

Inventory Management Systems: Platforms like **Lightspeed** or **Cin7** are designed to be this central hub from the ground up, with pre-built integrations for dozens of sales channels.

Custom Scripts: If your setup is particularly unique, you can hire a developer to write a custom script. They would use the APIs (Application Programming Interfaces) from both platforms to constantly check for sales and push updates back and forth.

Building this kind of multi-channel sync is a major leap forward. It directly solves the overselling problem and gives you a unified view of your inventory—something that's absolutely critical for scaling a business that operates both online and off.

Optimizing and Scaling Your Automated System

Getting your first automated workflow up and running is a fantastic first step. But the real gains come from treating your system as something that grows with you, not as a one-and-done project. True automation isn't about "setting it and forgetting it." It's about creating a system that evolves, gets smarter, and becomes more valuable to your business over time. This is how you shift from simply saving a few hours to genuinely driving growth.

The journey starts with diligent monitoring. You need to get good at spotting hiccups before they cause real problems for your operations or, worse, your customers. Your automation tools, like Zapier, keep a log of every single action. Make it a habit to check these logs. Look for failed tasks, script errors, or API timeouts. I always recommend setting up automated alerts for these failures—it's the only way to stay ahead and keep the system running smoothly.

Evolving From Reaction to Prediction

Once your system is stable and you have a good handle on monitoring it, you can move on to the more exciting stuff. All the data your new automations are gathering is pure gold. Instead of just looking back at what happened, you can start using that data to predict what’s going to happen. This is the core of scaling your inventory management—it’s about becoming predictive, not just reactive.

A huge part of this is demand forecasting. With all your sales data now clean and in one place, you can start spotting powerful trends.

Seasonality: Do you sell a ton of a specific product every holiday season? The data will show you exactly when to stock up, so you’re never caught off guard.

Sales Velocity: How fast does a particular item sell out after you restock it? Knowing this helps you set much smarter reorder points.

Product Bundles: Do customers who buy Product A almost always buy Product B too? This kind of insight is invaluable for marketing and deciding what to keep in stock.

This data-driven mindset lets you set dynamic reorder points. Instead of just using a fixed number like "reorder when stock hits 20," your system can adjust that threshold based on recent sales speed, seasonality, or even an upcoming marketing campaign. For those of us dealing with physical inventory, especially in construction, you can even layer in a material cost predictor to sharpen your purchasing by anticipating future price changes.

Empowering Your Team to Work With Automation

Here’s a piece of the puzzle that often gets missed: the human element. Automation isn't here to replace your team. It's here to free them from tedious work so they can focus on tasks that actually require a human brain. Think strategy, customer relationships, and creative problem-solving.

Training your team to trust the data and work alongside the new systems is paramount. They need to see the automation not as a threat, but as a powerful tool that makes their jobs easier and more impactful. When your team understands and trusts the system, they become its biggest champions.

This blend of people and technology is where the industry is heading. Predictive analytics and AI are becoming essential for inventory control. Consider this: by 2025, experts predict 4.28 million commercial warehouse robots will be installed globally, all to chase greater efficiency. You can explore more of these top warehouse statistics and industry trends on Omniful.ai to get a feel for the bigger picture.

By constantly optimizing your workflows, you’ll find efficiencies you never thought possible. To go even deeper, take a look at our guide on supply chain automation solutions that actually work. This cycle of monitoring, refining, and scaling is what ensures your investment in automation pays off for years to come.

Answering Your Top Questions About Inventory Automation

It's completely normal to have a few questions—and maybe even some doubts—as you think about making this change. Let's walk through some of the most common concerns I hear from business owners who are just starting to explore inventory automation. Getting straight answers will help you move forward with confidence.

How Much Is This Really Going to Cost Me?

The price tag for automating your inventory can swing wildly, from under $50 a month for some simple tools all the way up to thousands for a full-blown Warehouse Management System (WMS). But here's the good news: you don't have to jump into the deep end right away.

The trick is to stop thinking about cost and start thinking about value. A simple workflow connecting your online store to a spreadsheet, which you can build with a tool like Zapier, can give you an immediate win by preventing just one or two expensive stockouts. Prove the concept on a small scale first. Once you see the returns, it’s much easier to justify a bigger investment when you’re ready.

Will This Automation Make My Warehouse Team Obsolete?

This is a big one, but I've found the reality is often the complete opposite. Automation doesn't usually replace your team—it re-tasks them. Think about all the time your staff currently burns on mind-numbing work like manual counts, spreadsheet data entry, and fixing discrepancies. Those are low-value tasks where mistakes are bound to happen.

By automating that drudgery, you free them up to focus on work that actually requires a human brain.

Quality Control: Putting eyes on incoming shipments to make sure everything meets your standards.

Process Improvement: Finding smarter ways to lay out the warehouse or make picking and packing more efficient.

Customer Support: Handling tricky customer questions and building better relationships.

Ultimately, automation lets your team become more strategic. They can shift their energy to tasks that genuinely grow the business and keep customers happy.

What's the Single Biggest Mistake to Avoid?

If there's one pitfall I see businesses fall into over and over, it's automating a messy process. If your inventory data is a disaster zone—think inconsistent SKUs, different names for the same product, and disorganized supplier info—your shiny new automation will just make those mistakes faster.

Before you write a single line of code or build one workflow, you have to clean up your data. A clean, standardized foundation is the only way this works. Taking the time to get this right from the start will save you from a world of pain later.

How Quickly Will I See a Return on My Investment?

For small-scale automations, like the low-stock alerts we talked about earlier, the ROI can be almost instant. Preventing a single stockout on a bestselling item can easily cover the cost of a no-code tool for an entire year.

When you start looking at larger, more integrated systems, you can typically expect to see a payback within 6 to 18 months. That return comes from a mix of things: lower carrying costs, fewer lost sales from being out of stock, and a huge boost in labor efficiency. The most important thing is to start tracking your key numbers from day one so you can actually see the impact.

Ready to stop wasting time on manual tasks and build a more efficient, resilient business? At Flow Genius, we design and implement custom automation solutions that fit your exact needs. Book a discovery call today and find out how we can streamline your inventory management for good.