Your Process Improvement Plan Template Guide

- Matthew Amann

- Jul 27, 2025

- 14 min read

Think of a process improvement plan template as more than just a document—it's your blueprint for untangling messy business operations. It provides a consistent framework for spotting, analyzing, and fixing the inefficiencies that hold your team back, turning chaotic workflows into predictable, high-performing engines for growth.

Why a Process Improvement Plan Is Your Secret Weapon

Let's cut through the business jargon for a second. A process improvement plan isn't some abstract corporate exercise. It’s a hands-on tool that connects the big idea of "getting better" to the real, everyday headaches your team actually experiences.

We’ve all seen them—those nagging problems that suck up time, money, and morale. A solid plan is built to target and eliminate these very issues.

Frustrating Bottlenecks: Maybe your customer support team is always playing catch-up, missing response time goals because tickets get lost in a black hole between departments.

Inconsistent Output: Or perhaps the manufacturing line has "good days" and "bad days," producing a high number of defects with no clear reason why.

Team Burnout: It could be that your best people are buried under a mountain of tedious, manual tasks that kill their engagement and make them look for the door.

These aren't just minor annoyances. They're symptoms of broken processes that are actively damaging your bottom line and your company culture.

From Chaos to Clarity

This is where a good process improvement plan template becomes your roadmap. It forces you to stop just talking about problems and start methodically breaking them down. This disciplined approach is how you turn unpredictable, chaotic operations into smooth, reliable systems.

Take a marketing team, for example, that consistently fumbles the handoff of qualified leads to the sales team. Instead of finger-pointing, they can use a plan to map out the entire process. They’d pinpoint exactly where things go wrong and then design a new, crystal-clear protocol with defined ownership. It's not just about fixing one broken link; it’s about creating a problem-solving muscle your organization can use again and again. To dig deeper into different frameworks, you can explore our guide to process improvement methodology.

The real magic of a formal plan is the discipline it creates. It shifts your team from a constant state of reactive "firefighting" to a proactive mindset where you're deliberately building a more efficient and successful work environment.

The Critical Role of a Structured Plan

Here's a hard truth: without a documented plan, most improvement efforts are doomed from the start. They fizzle out due to fuzzy goals, no clear ownership, and no way to tell if you've actually succeeded. This is a classic trap. So many companies are great at identifying problems but stumble when it comes to executing a solution.

The data backs this up. According to extensive research from Prosci, only about 13% of organizations with poor change management practices actually meet their project goals. That number tells a powerful story. A structured plan is what gives your initiative the backbone it needs—securing stakeholder buy-in and defining the clear, measurable steps required to make change stick.

Before diving into creating your own, it helps to understand the fundamental building blocks. A truly effective plan template will always have a few core elements that guide your thinking and actions.

Core Components of an Effective Process Improvement Plan

Here’s a breakdown of the essential pieces your template should include. Think of this as your checklist for building a plan that actually works.

Component | Purpose and Key Questions to Answer |

|---|---|

Problem Statement & Goal | Clearly define the specific issue you're tackling and what success looks like. What is the exact problem? What measurable outcome are we aiming for? |

Current Process Analysis | Map out the existing workflow to find the root cause of the problem. How does the process work today? Where are the bottlenecks, delays, or errors? |

Proposed Solution | Detail the specific changes you plan to implement. What new steps, tools, or roles will be introduced? How will this solve the root cause? |

Key Performance Indicators (KPIs) | Identify the metrics you'll use to measure improvement. How will we know if we've succeeded? What data will we track before and after? |

Action Plan & Timeline | Break the solution down into concrete tasks with deadlines and owners. Who is responsible for what? When does each step need to be completed? |

Resource Allocation | Outline the budget, tools, and people required to execute the plan. What do we need to make this happen? Is the budget approved? |

Stakeholder Communication | Plan how you'll keep everyone informed and engaged throughout the process. Who needs to be in the loop? How and when will we share updates? |

Having these components built into your template ensures you cover all your bases, moving from a vague idea to a concrete, actionable project with a high chance of success.

Building Your Own Process Improvement Plan

Moving from theory to action is where the real work of process improvement begins. Crafting a solid process improvement plan template isn't about downloading a generic document; it's about building a living framework that molds to your team's unique challenges and workflows. Let's get practical and talk about how to create a plan that actually solves problems.

The foundation of any good plan is an honest, unflinching look at your current reality. You can't fix what you don't fully understand. This is where you have to roll up your sleeves and map out the workflow as it exists today—warts and all.

Visualizing Your Current State

One of the most powerful things you can do first is process mapping. It’s simply creating a visual diagram of every single step in a workflow, from the very beginning to the very end. Think of it like drawing a map, but instead of searching for treasure, you're hunting for bottlenecks, redundant tasks, and frustrating delays.

For instance, I once worked with a marketing team that was struggling with a terrible lead handoff process. We mapped the entire journey of a new lead and discovered something shocking: leads were sitting in an unmonitored inbox for a full 48 hours before a salesperson ever saw them. It was a massive, obvious point of failure that had been completely invisible to management.

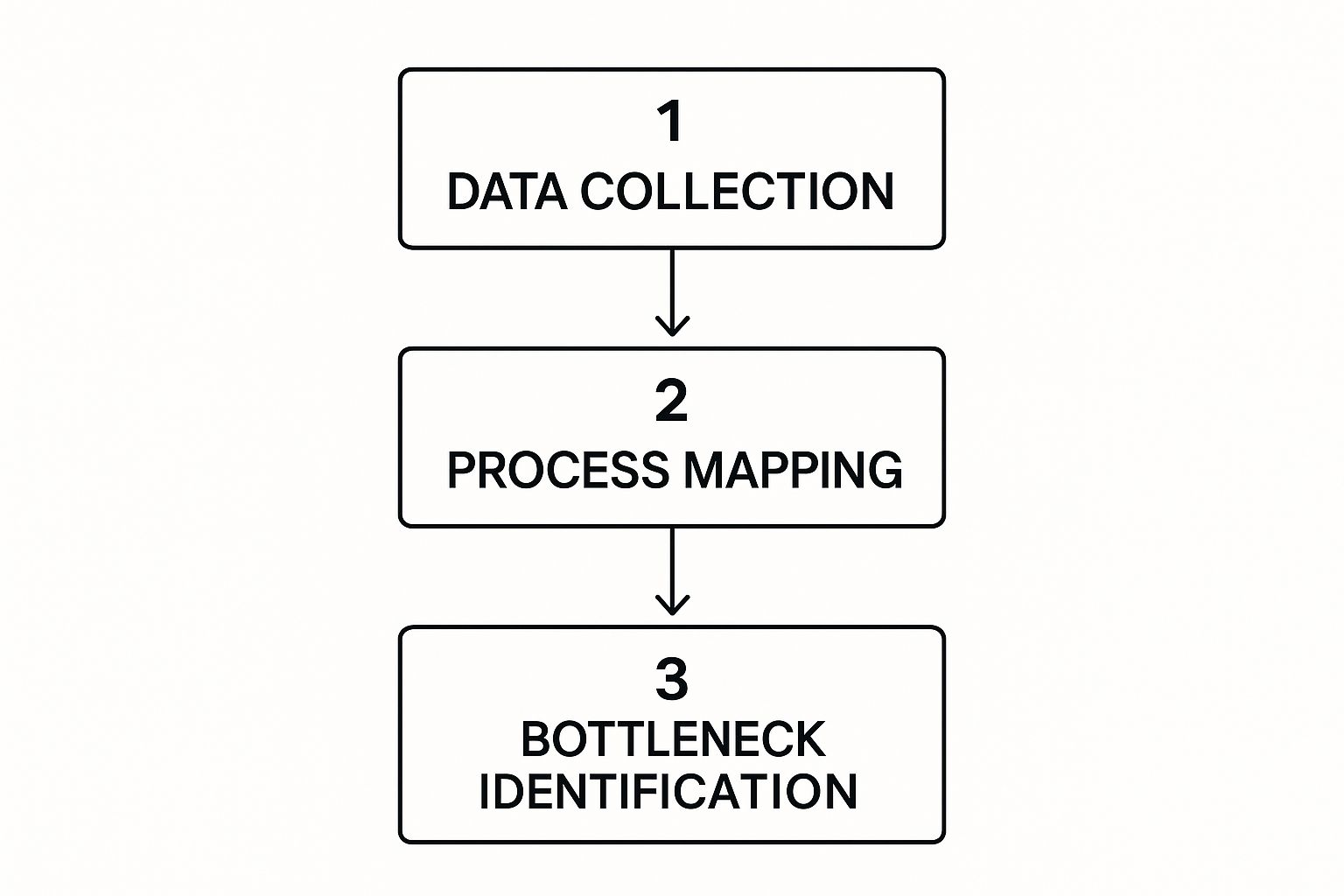

This simple flow chart illustrates the basic discovery sequence.

Following a path like this helps you move from gathering general information to pinpointing the exact source of your process headaches.

Digging for the Root Cause

Once you can see the process, the next step is to diagnose the problem correctly. It’s far too easy to treat the symptoms while completely ignoring the underlying disease. A fantastic tool for this is the 5 Whys technique. It's a surprisingly simple but profound method where you just keep asking "Why?" until you uncover the real root of the issue.

Let's say an operations team is dealing with a lot of wasted inventory.

Problem: We're throwing away too much raw material.

Why? Because we keep ordering more than we actually need.

Why? Because our demand forecasts are consistently wrong.

Why? Because the production data we use is always delayed.

Why? Because operators have to enter it all manually at the end of a long shift.

Root Cause: The lack of a real-time data entry system is causing bad forecasts.

See the difference? The solution isn't "order less stuff." It's "get a real-time data system." This targeted approach ensures you’re fixing the actual problem for good. As you build your plan, exploring different process improvement techniques will give you a much richer toolkit for this kind of analysis.

The most critical insight you can gain comes from the people who live the process every day. Their firsthand experience is more valuable than any spreadsheet. Involve them early and often.

Grounding Your Plan in Reality

A plan cooked up in a boardroom without input from the front lines is almost guaranteed to fail. The people doing the work are the ones who know the real-world nuances, the clever workarounds, and the hidden frustrations that never make it onto an official process chart. Their involvement is non-negotiable if you want to create solutions that are both effective and practical.

To ground your plan in the real world, make data collection a team sport.

Conduct Interviews: Just sit down with team members and have a conversation. Ask open-ended questions about their daily work and what drives them crazy.

Host Workshops: Get everyone in a room with a whiteboard and map the process together. You'll be amazed at what comes out.

Observe Directly: Spend some time just watching the process in action. See it with your own eyes.

By blending the qualitative insights from your team with hard, quantitative data, you create a complete picture of the problem. This dual approach ensures your process improvement plan template becomes more than a document—it becomes a true blueprint for meaningful change.

Getting Your Plan Off the Ground and Rallying the Team

A brilliant plan on paper is just that—paper. Its real value comes alive when you actually put it into motion and, crucially, get your team to believe in it. This is where the human element comes in, and it's where even the most perfectly designed process improvement plan template can stumble if you don't handle it right.

Your main goal here is to build confidence, not fear. Change almost always gets a skeptical reception, so your communication has to be clear, proactive, and genuinely empathetic. Don't just announce a new process. You have to sell the vision and earn true buy-in from everyone—from senior leaders to the frontline folks whose day-to-day work is about to change.

Start with a Pilot Test

Before you go all-in with a company-wide rollout, do yourself a favor and run a small-scale pilot test. Think of it as a dress rehearsal. It’s your chance to iron out unexpected wrinkles, get feedback from people on the ground, and fine-tune the process in a low-stakes environment.

A pilot test is all about minimizing risk while building momentum. For instance, if you’re revamping your invoicing workflow, maybe you test the new steps with just two or three trusted clients first. This lets the finance team adjust without the immense pressure of managing every account under the new system. A win here gives you a powerful success story to help convince everyone else.

Make Roles and Responsibilities Crystal Clear

Nothing kills execution faster than ambiguity. When people aren't sure who's supposed to do what in a new process, tasks get missed, deadlines slip, and frustration mounts. This is precisely where a RACI chart can be a lifesaver. It’s a simple matrix that defines who is:

Responsible: The person (or people) doing the actual work.

Accountable: The single person who ultimately owns the outcome. This is the buck-stops-here role.

Consulted: The experts you need to get input from before the work is done.

Informed: The people you need to keep in the loop on progress.

When you map out every key task against these roles, you eliminate the guesswork. Everyone knows exactly what's expected of them, which is absolutely essential for making the change stick.

A well-communicated plan with clear roles turns potential resistance into active participation. When people understand the 'why' behind the change and see their specific part in it, they are far more likely to become champions of the new process.

This structured approach to testing and refining is a cornerstone of successful methodologies you see everywhere, from ISO 9001 standards to Agile development. The classic Plan-Do-Check-Act (PDCA) cycle is built on this very idea, providing an iterative framework that’s fundamental for making sure process improvements last.

As you implement your plan, you'll likely be looking for ways to streamline tasks even further. Exploring different workflow automation examples can spark some great ideas for boosting efficiency across your operations. In the end, managing this change proactively is how you turn a document into a living, breathing part of your company's culture—paving the way for real, lasting improvement.

How to Measure What Matters

So you've rolled out your new process. The big question now is, did it actually work? Without solid metrics, you're just operating on a hunch. Measuring what matters is what closes the loop, turning a one-off fix into a repeatable system for getting better.

This is where you need to get brutally honest about defining Key Performance Indicators (KPIs) that connect directly to the original problem. Vague goals like "making things more efficient" won't cut it. You need hard, specific targets that leave no room for debate.

Defining Your Success Metrics

Your best KPIs come straight from the problem statement you wrote at the very beginning. If you were trying to fix painfully slow customer service, your main KPI is response time. Simple as that. If you were tackling shoddy products coming off the line, your KPI is the defect rate.

Think in concrete terms. Here are a few examples I've seen work well:

Goal: Knock 30% off our average customer ticket response time this quarter.

Goal: Slash material defects on the assembly line by 25% within the next six months.

Goal: Get new client onboarding down from a 10-day slog to a 5-day sprint.

These aren't just goals; they're clear, time-bound benchmarks. They tell you exactly what success looks like. To make sure your improvements stick and don't just create new problems, solid quality control is crucial. You can find some great advice on effective quality assurance to pair with your measurement plan.

Your best KPIs tell a story. A falling defect rate isn't just a number on a chart—it's a story about better quality, less wasted material, and customers who trust your product. That's the story you want your data to tell.

Tracking Progress Without the Headache

Here's a trap I've seen teams fall into: they spend more time manually tracking the new process than they save from the improvement itself. Don't do that. The entire point is to track progress efficiently, not to build a massive reporting spreadsheet that everyone dreads opening.

Automate data collection wherever you can.

Most of the software you already use—your CRM, project management platform, or inventory system—has reporting features built right in. Use them! If your helpdesk tool can spit out an "average response time" report, put that on a dashboard. If your manufacturing software can track scrap material, set up an automated alert. This isn't just about saving time; it's about getting past the obvious numbers. For a deeper dive, take a look at our guide on how to measure operational efficiency beyond basic metrics.

Establishing a Rhythm of Review

Data that just sits on a dashboard is worthless. You have to build a regular routine for looking at it and talking about what it means. This isn't about micromanaging your team; it's about holding everyone accountable and learning from what the numbers are telling you.

Here's a simple cadence that works for many teams:

Weekly Check-ins: A quick 15-minute huddle to spot any early trends, good or bad. Perfect for fast-moving processes.

Monthly Reviews: A more formal look to see how you’re tracking against the big-picture goal.

Quarterly Strategy Sessions: This is where you step back, evaluate the overall success of the project, and decide where to focus next.

This rhythm turns measurement from a boring chore into a powerful team habit. It gets the "Plan-Do-Study-Act" cycle baked into your culture, ensuring that the success of one process improvement plan template becomes the launchpad for the next one. This is how you finally stop playing whack-a-mole with problems and start building a real culture of continuous improvement.

Common Process Improvement Pitfalls to Avoid

It's one thing to have a solid plan, but knowing what not to do is often just as important. I’ve seen countless well-intentioned process improvement projects go off the rails because of a few common, and entirely avoidable, traps.

One of the biggest culprits? Analysis paralysis. It’s that classic scenario where a team gets so tangled up in studying a problem, collecting data, and debating every possible solution that they never actually get around to making a change. Remember, the goal is progress, not absolute perfection from the start.

Another guaranteed way to stumble is to create a plan in an echo chamber. If you don't bring the people who live and breathe the process every day into the conversation, you're flying blind. This almost always results in solutions that sound great in a meeting room but fall apart the second they hit the real world.

Starting Too Big

It’s tempting to try and fix everything at once. We’ve all been there—a team gets fired up and decides to overhaul a massive, company-wide process right out of the gate. This rarely ends well. The complexity quickly becomes overwhelming, managing all the stakeholders turns into a full-time job, and the project timeline drags on forever.

A much smarter approach is to think like a surgeon, not a bulldozer. For your first project, find a single, manageable process that's causing real frustration but is small enough to improve quickly. Nailing a quick win builds incredible momentum. It proves the value of using a structured process improvement plan template and makes it far easier to get support for bigger projects later on.

The most powerful improvements often come from small, focused changes that compound over time. Aim for a single, undeniable success first to build the confidence and political capital you’ll need for bigger challenges down the road.

Overlooking the Human Element

Many plans get hyper-focused on the technical side of things—the software, the workflow, the handoffs—while completely forgetting about the people involved. Change, even positive change, can be met with skepticism or resistance. If your plan doesn't account for the human side of the equation, you're fighting an uphill battle.

To get ahead of this, build answers to these questions directly into your plan:

Why is this change happening? Be transparent. Clearly explain the problem you’re solving and what the benefits are for both the team and the company.

What does this mean for me? Address individual concerns head-on. Explain how roles might shift and, crucially, provide the training and support to help people succeed.

Who do I talk to if I have issues? Create clear, open channels for feedback and questions. Don't let frustrations fester.

Effectively navigating these challenges often comes down to choosing the right methodology. You can explore your options in our guide to 9 key process improvement techniques to use in 2025. By anticipating these common pitfalls, you can steer your team around them and ensure your efforts lead to real, sustainable results.

Your Top Questions Answered

When you're first digging into process improvement, a lot of questions pop up. It's completely normal. Getting those initial uncertainties cleared up is key to moving forward with confidence. Here are some of the most common questions we get from teams who are just starting out, along with some straight-to-the-point answers.

How often should we actually review our processes?

That's a fantastic question, and the real answer is: it depends. There’s no magic number that works for every single process. The best approach is to tailor your review schedule to how critical and how volatile the process is.

For fast-moving or high-stakes workflows—like the steps in a new digital marketing campaign or a recently launched customer support protocol—a quarterly review is a good rule of thumb. It keeps you agile. But for those more settled, stable processes like annual budget approvals or standard employee onboarding, an annual review is usually more than enough.

The point isn't to just tick a box on a calendar. You're trying to build a consistent rhythm of evaluation. This way, you spot potential problems and opportunities proactively instead of just reacting when things go wrong.

What’s the real difference between process improvement and project management?

It's easy to see why these two get mixed up, but knowing the difference is vital. Here’s a simple way to think about it.

Process Improvement is all about refining a repeatable, ongoing workflow. The aim is to make a routine task better over the long haul—more efficient, more effective, more reliable. You're raising the standard for how you operate day-to-day.

Project Management is for executing a unique, one-off effort. It has a clear beginning and end, a specific scope, and defined deliverables. It’s about getting a temporary initiative across the finish line successfully.

Ironically, you'll often use project management to implement your process improvement plan. The plan is the "what" and "why," and project management is the "how" and "when" that makes it happen.

Who needs to be in the room when we create the plan?

Trying to build a process improvement plan by yourself is a recipe for disaster. To create something that actually holds up in the real world, you need a mix of perspectives. We've found the most successful teams always involve three key types of people.

The People on the Ground: The folks who execute the process every single day are your most critical asset. They're the real experts who know where the true bottlenecks and workarounds are hidden.

The Manager: You need the team lead or direct manager in the mix. They provide the bigger picture, help clear away obstacles, and make sure any changes fit with the team's wider objectives.

The Stakeholder: Always include someone who receives the output of the process. This might be a person from another department or even a team member who deals directly with customers and feels the impact of how well (or poorly) the process works.

Bringing these three voices together ensures your plan is practical, strategically sound, and built for the way work actually gets done.

Ready to stop wasting time on manual tasks and build truly efficient workflows? At Flow Genius, we specialize in designing and implementing smart automation solutions that eliminate bottlenecks and give your team back its most valuable resource—time. Let's build a blueprint for your business's success together.