Optimize Warehouse Operations: Insider Strategies That Work

- Jun 10, 2025

- 13 min read

Uncovering The Efficiency Drains Nobody Talks About

Let's be honest, most warehouse operations are leaking money. And often, it's not showing up in your regular reports. I've worked with tons of warehouse managers who've made huge changes to their processes, and one thing always comes up: the real budget killers aren't the obvious problems. It’s the small, almost invisible inefficiencies that add up and really drain your profits. Think of it like a tiny leak in a pipe – it might not seem like much at first, but over time, it wastes a ton of water (and money!).

One common example is excess movement. Are your pickers zigzagging across the warehouse more than they need to? Are items stored in weird spots, making staff backtrack all the time? These little things add up to wasted time and lower productivity. Another hidden drain is poor communication. How much time gets lost because of confusing instructions, misplaced paperwork, or hunting for missing items? These small delays can cause late shipments and unhappy customers – not a good mix!

Identifying Hidden Costs in Your Warehouse

These hidden costs are often hard to put a number on, but they have a big impact on your profits. Imagine a picker spends just five extra minutes per order looking for misplaced items. If they handle 50 orders a day, that's over four hours of wasted time – almost half a shift! Now think about how many pickers you have, and suddenly the cost is huge. Want to boost productivity? Check out this article on improving workflow efficiency.

Let's face it, technology is changing everything, including warehouse operations. By 2025, there are projected to be around 4,281,585 commercial warehouse robots installed globally, completely changing how warehouses manage labor and operations. This isn't some sci-fi future, it's happening now. Learn more about warehouse statistics and industry trends.

Here's a quick look at some common warehouse inefficiencies and the hidden costs associated with them:

Inefficiency Type | Warning Signs | Cost Impact | Difficulty to Fix |

|---|---|---|---|

Excess Movement | Pickers crisscrossing warehouse, illogical item placement | Increased labor costs, reduced picking rates | Medium |

Poor Communication | Misplaced paperwork, unclear instructions, time spent searching for items | Delayed shipments, customer dissatisfaction, lost productivity | Medium |

Inventory Inaccuracies | Stockouts, overstocking, expired inventory | Lost sales, increased storage costs, waste | High |

Inefficient Picking Processes | Manual picking, paper-based systems | Slow picking rates, high error rates | Medium |

Inadequate Storage Space | Cluttered aisles, difficulty locating items | Reduced storage capacity, safety hazards | High |

The table above highlights just how much seemingly small inefficiencies can impact a warehouse's bottom line. Addressing these issues can significantly improve efficiency and free up resources.

Practical Assessment For Real Results

So, how do you find these hidden drains in your warehouse? Start by simply observing. Spend time on the warehouse floor, not just in the office. Watch how your team works and ask them about their biggest frustrations. You’ll be surprised by what you learn. Look for patterns of wasted movement, unnecessary steps, and communication breakdowns.

Even small improvements can make a big difference. Something as simple as reorganizing a picking zone or creating a clearer labeling system can have surprisingly significant results. You can also check out resources like this guide on implementing ideas effectively. These small wins build momentum and create a culture of continuous improvement. Remember, optimizing warehouse operations isn't about huge overhauls, it’s about consistently finding and fixing those small leaks that drain your profits.

Workflow Mapping That Reveals The Real Story

Forget those polished process diagrams hanging in the boardroom. They might look impressive, but often they're miles away from what's actually happening on your warehouse floor. This is about getting down to brass tacks and understanding the real, day-to-day flow of work. From small, single-zone operations to massive multi-facility networks, I’ve seen firsthand how mapping real-world movements can uncover some pretty surprising inefficiencies.

Documenting The Undocumented: Practical Techniques

So, how do you document these real-world processes without disrupting your daily operations? The key is to get your team involved right from the start. They're the ones in the trenches every day, so they have invaluable insights. Plus, their involvement creates buy-in for any future changes. Trust me, this makes a world of difference.

Keep the tools simple. Think sticky notes on a whiteboard to represent different zones, string or tape to visualize movement pathways, even time-lapse videos of key processes. You don't need anything fancy. I once worked with a small warehouse that used colored tape to track forklift routes. This simple solution revealed major crossover points that were causing unnecessary delays.

Visualizing The Flow: From Chaos to Clarity

The goal isn't just documentation for documentation's sake; it's about getting actionable intelligence. Where are the real bottlenecks? Which processes are unnecessarily complex? Where can you consolidate tasks and optimize movement? These are the questions workflow mapping helps you answer. Visualizing your workflow like this can be a real game-changer.

This screenshot from Wikipedia's Warehouse Management System page gives you a peek into the software side of warehouse operations. While a WMS is definitely important, the real magic happens when you combine it with an understanding of the physical flow of your team and products. That combination is where you unlock real efficiency.

From Maps to Action: Identifying Opportunities

Once you've mapped your workflows, don't just let them gather dust. Put them to work! Analyze the flow, looking for areas where processes overlap, create confusion, or cause delays. Identify high-traffic areas that might benefit from reorganization or even automation. Remember, the map is just the starting point. The real value is in taking those insights and turning them into action. A clear understanding of your current situation is crucial before you can start making meaningful improvements.

Smart Automation Choices For Your Actual Budget

Let's be honest, the term "warehouse automation" can conjure up images of million-dollar robots and spaceships. But some of the most impactful efficiency gains I've witnessed come from far simpler, budget-friendly solutions. It’s not always about robotic arms; sometimes, it’s about smartly linking the systems you already have. We'll explore these practical options, from workflow automation tools like Zapier and Make.com to more advanced warehouse management systems (WMS). You'll gain a clear understanding of when each approach is financially sound, avoiding expensive overkill.

Balancing Cost and Benefit: Automation That Pays For Itself

Over the years, I've spoken with countless warehouse operators who have experimented with different levels of automation. A key takeaway is that some technologies offer a quick return on investment (ROI), while others are more suitable for later stages of growth. For example, using a tool like Zapier to set up automatic low stock alerts can be incredibly cost-effective and prevent stockouts, saving you money fast. Conversely, a full-blown WMS might be a larger investment, but essential for scaling your operations effectively.

This screenshot shows the Zapier interface, a visual platform for connecting different apps and automating tasks. The real beauty of these tools lies in their simplicity. They empower you to connect existing software and automate repetitive tasks without needing complex coding. This frees your team to focus on more strategic work. To streamline processes and boost efficiency even further, consider implementing robust document workflow solutions.

Custom Solutions: When Off-The-Shelf Isn’t Enough

Sometimes, your processes are so unique that standard automation tools simply won’t do. That's where custom scripting enters the picture. While it can be more complex, it offers the flexibility to automate precisely what you need. I once worked with a warehouse that implemented custom scripts to integrate their inventory system with their shipping provider, saving them hours of manual data entry every single day. This level of tailored automation can dramatically optimize warehouse operations, especially when dealing with unique or complex workflows. Warehouse management systems (WMS) have become vital for optimizing warehouse operations. A robust WMS can automate several key processes, including inventory management, order fulfillment, receiving and putaway, workforce scheduling, and shipping operations. Discover more insights.

Practical Integration: Avoiding the Automation Pitfalls

Automation isn't a magic wand. Integrating new systems can be tricky. I’ve seen companies jump headfirst into automation, only to create operational chaos. The key is a phased approach. Start small, test thoroughly, and bring your team along for the ride. Focus on integrating one system at a time, ensuring smooth operation before adding another. This measured approach prevents overwhelming your team and minimizes disruptions to your daily workflow.

To help you choose the right automation solutions for your needs, I've put together a comparison table:

Automation Solutions Comparison by Warehouse Size and Budget: This table provides a detailed comparison of automation options, implementation costs, and expected ROI for different warehouse scales.

Solution Type | Best For | Implementation Cost | Time to ROI | Complexity Level |

|---|---|---|---|---|

Basic Workflow Automation (Zapier/Make) | Small to Medium Warehouses, Limited Budget | Low | Short | Low |

Custom Scripting | Medium to Large Warehouses, Unique Needs | Medium to High | Medium | Medium to High |

Full WMS | Large Warehouses, High Volume | High | Long | High |

As you can see, the best solution depends on your specific circumstances. While a full WMS might be ideal for a large operation, a smaller warehouse can achieve significant gains with more basic tools.

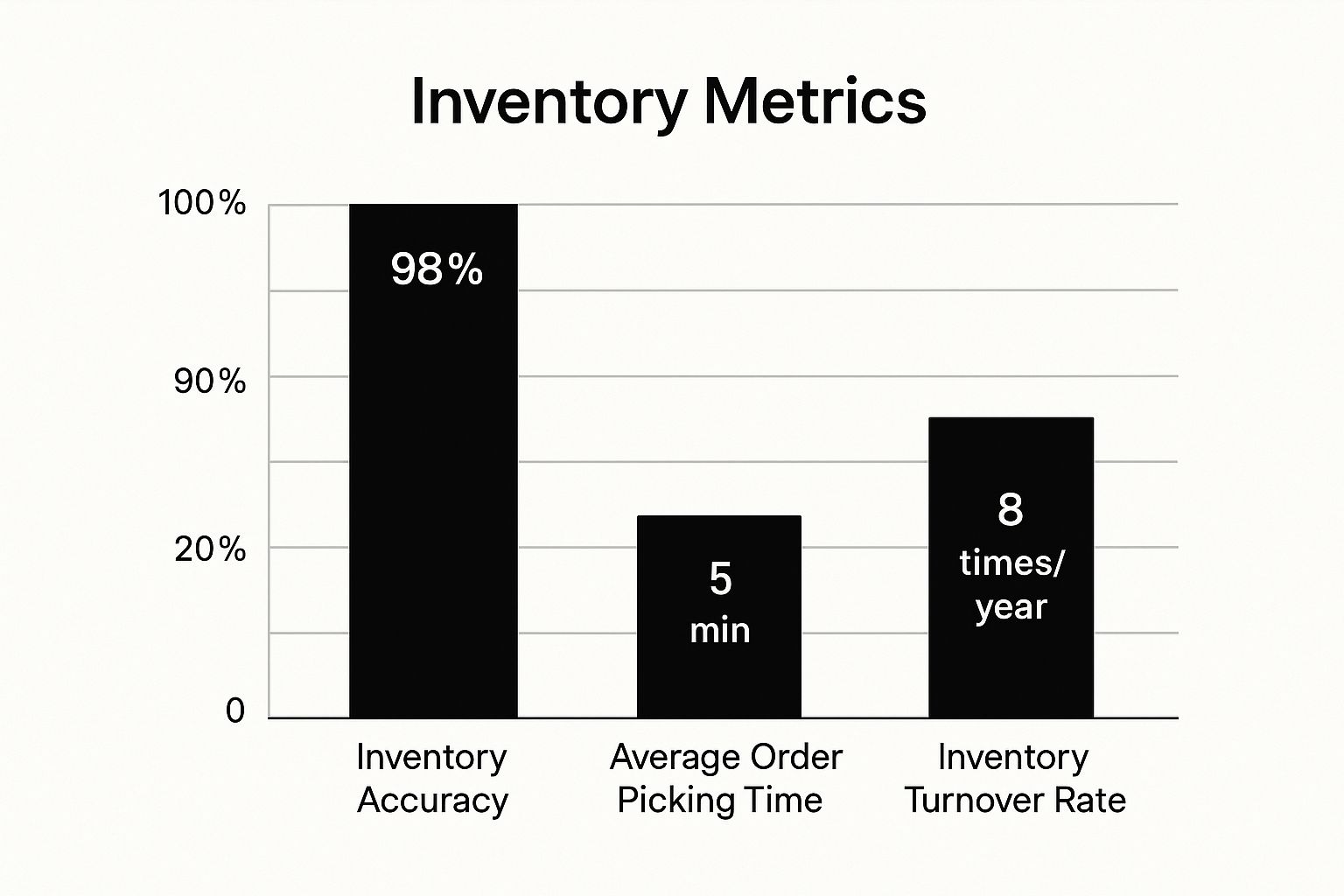

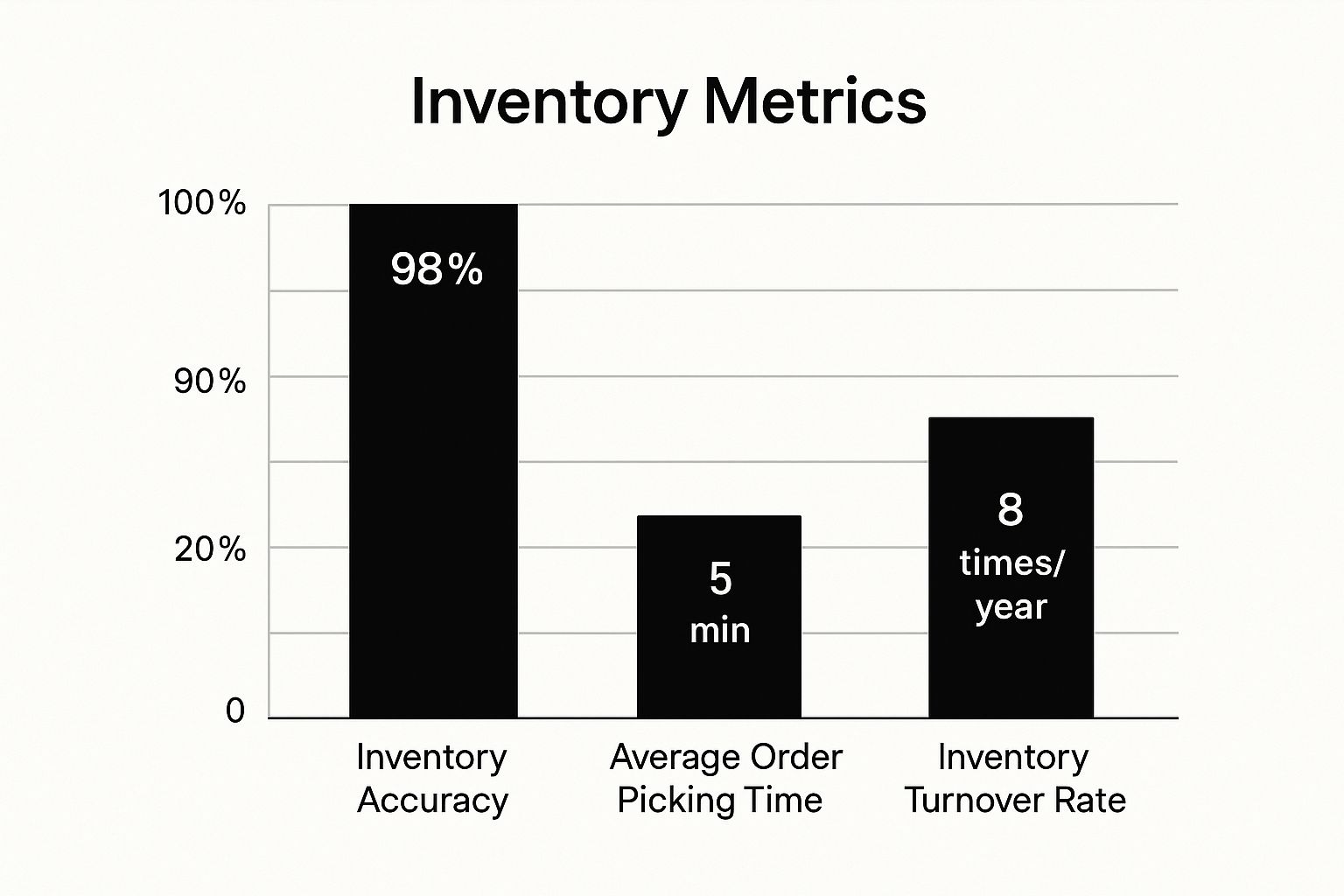

This infographic visualizes key warehouse performance metrics: Inventory Accuracy, Average Order Picking Time, and Inventory Turnover Rate. These metrics are crucial for understanding the overall health and efficiency of your warehouse. Reaching 98% inventory accuracy, reducing average picking time to 5 minutes, and achieving an 8x inventory turnover rate indicates a highly efficient operation. These interconnected improvements highlight the power of well-implemented automation. Remember, automating your warehouse is an ongoing process, not a destination. Begin with what fits your budget and build from there, continually refining your processes for peak performance.

Integration Strategies That Don't Create Chaos

Let's be honest, integrating new systems into a bustling warehouse can feel like trying to change a tire on a moving car. I've witnessed firsthand how well-meaning upgrades can descend into utter chaos simply because the integration process wasn't thought through. So, how do you implement these changes smoothly, without grinding productivity to a halt? Let me share some insights gleaned from conversations with warehouse teams who've navigated these tricky waters.

Training and Transitioning: Keeping the Wheels Turning

Consider your team. How can you possibly train them on new software while they're juggling their daily responsibilities? Phased rollouts are a lifesaver here. Start with a small pilot group. Let them get acquainted with the system, identify any hiccups, and provide valuable feedback before you roll it out to everyone. This minimizes disruption and lets you iron out any wrinkles early on. Also, weave in hands-on training sessions during quieter periods. Short, focused bursts are way more effective than marathon lectures.

Remember, change can be unsettling. Address any resistance head-on. Clearly explain the why behind the new systems. Emphasize how they'll simplify tasks and improve their workday. Listen to concerns, offer support, and show empathy. A little understanding can go a long way.

APIs and Data Migration: The Technical Nitty-Gritty

On the technical side, API integrations are incredibly powerful, but they can also be a real pain if not handled correctly. Make absolutely sure your chosen systems can communicate seamlessly. Thoroughly test these integrations in a sandbox environment before going live. This will prevent unpleasant surprises down the road. For example, if you're integrating a new Warehouse Management System (WMS) with your existing Order Management System (OMS), test the data flow rigorously. This ensures accuracy and prevents data loss. You might find these data integration best practices helpful.

Data migration is another crucial aspect. You definitely don't want to lose valuable historical data during the transition. Back everything up – and then back it up again! Consider using a staging server to rehearse the data migration process before touching your live database. This drastically reduces the risk of errors and data corruption. Think of it as a dress rehearsal before the big show.

Backups and Troubleshooting: Planning for the Unexpected

Even the most meticulous plans can go awry. Solid backup processes are essential. Maintain regular backups throughout the integration. This way, you can quickly restore your systems if things take an unexpected turn. Imagine the peace of mind knowing you can easily revert to a previous state if necessary.

Lastly, create a troubleshooting plan. Anticipate potential issues and brainstorm solutions before they arise. This might involve a detailed FAQ for your team or dedicated communication channels for reporting problems. Consider it your emergency preparedness kit for your warehouse optimization project. By proactively addressing these integration challenges, you’ll not only avoid chaos but set your team up for lasting success.

Measuring Progress That Actually Matters

Beyond simply counting how many items are processed per hour, let’s look at the metrics that truly indicate long-term success and sustainable profits for your warehouse. Having seen the data from tons of successful warehouse transformations, I can tell you the facilities that maintain their improvements focus on very different Key Performance Indicators (KPIs) than you might expect. Think of it like this: measuring only items processed is like judging a restaurant solely on how many plates they serve. You're missing crucial elements like food quality and customer satisfaction.

Establishing a Meaningful Baseline

Before making any changes, you need a solid grasp of your current performance. This means establishing a baseline. Don't just grab the latest numbers – look at trends over time. What's the average order fulfillment time? What’s your current inventory accuracy? What percentage of shipments are delivered on time? These baseline measurements become your benchmark for evaluating the real impact of your optimization efforts. Think of it as taking a "before" picture so you can accurately assess the "after."

Tracking Progress Without Vanity Metrics

During implementation, it's easy to get distracted by vanity metrics that look good on paper but don't reflect real improvement. For example, a small increase in items picked per hour might not matter if your error rate also increases. Focus instead on leading indicators that predict long-term gains. Is employee satisfaction improving? Are communication breakdowns decreasing? Are you seeing fewer stockouts? These indicators often signal real operational improvement before it shows up in your bottom line.

KPIs That Predict Long-Term Success

So, what are these crucial KPIs that top-performing warehouses focus on? Here are a few examples:

Order fulfillment cycle time: This measures the total time from order placement to delivery. Reducing this time directly improves customer satisfaction and can even boost sales.

Inventory turnover rate: A higher turnover rate means you’re efficiently managing your inventory, minimizing storage costs and the risk of items becoming obsolete.

On-time shipping rate: Meeting delivery deadlines is essential for keeping customers happy and avoiding penalties.

Cost per shipment: This metric includes all costs associated with fulfilling an order, like labor, materials, and overhead. Lowering this cost directly impacts profitability.

Employee satisfaction: Happy employees are more productive and less likely to leave. Measuring their satisfaction gives you valuable insights into how your changes are impacting your team.

Data-Driven Continuous Improvement

The most successful warehouses don’t just monitor data; they use it to continuously refine their operations. They analyze trends, identify areas for improvement, and make adjustments based on real-world performance. It’s an ongoing cycle of learning and adapting. You might find this resource on maximizing automation ROI helpful for further enhancing your data-driven approach.

For example, if your data shows a recurring delay in a specific part of the fulfillment process, you can investigate the root cause and implement targeted solutions. This could involve tweaking workflows, retraining staff, or even investing in new tech. Remember, optimizing your warehouse operations isn’t a one-time project—it’s an ongoing journey. By focusing on the right metrics and using data to inform your decisions, you can achieve sustainable improvements that drive real business value.

Making Improvements Stick Long-Term

The toughest part of optimizing a warehouse isn't making the initial changes. It's stopping those improvements from fading away over time. Think of it like a new diet: the first few weeks are easy, driven by excitement, but the real test is maintaining that momentum long-term. This section covers how to make those hard-won gains last, based on my experience with warehouse managers who've successfully sustained improvements for years, even through seasonal peaks and staff turnover.

Building a Culture of Continuous Improvement

Lasting change means baking continuous improvement into your warehouse culture. This doesn’t mean more bureaucracy or endless meetings. It’s about creating an environment where small, incremental improvements are everyone’s daily habit. I've seen warehouses use simple systems like a quick daily "huddle" where staff discuss challenges and ideas. Even a suggestion box can make a difference. The goal is to foster ownership and encourage everyone to contribute.

Accountability That Empowers, Not Oppresses

Accountability is key, but it shouldn't feel like punishment. The best warehouses I’ve seen use supportive accountability systems. This means setting clear performance expectations, providing regular feedback, and recognizing improvements. For example, some warehouses track team performance on overall order accuracy and on-time shipments, instead of just individual picking rates. This encourages collaboration and shared goals.

Adapting to the Ever-Changing Landscape

Business needs are always changing. What works today might not work tomorrow. The key is creating flexible and adaptable processes. I once worked with a warehouse experiencing rapid expansion. Their initial picking process, optimized for a smaller operation, needed an overhaul. They adopted zone picking and introduced automated guided vehicles (AGVs) to handle the increased volume. This flexibility allowed them to maintain efficiency even as they scaled.

Ongoing Training That Doesn't Feel Like Punishment

Continuous training is essential. However, it shouldn't feel like a chore. I've seen warehouses integrate short, focused training sessions into regular schedules. Some even use gamification to make learning fun. The goal is to keep skills sharp without disrupting daily operations.

System Maintenance: Preventing Small Issues From Becoming Big Problems

Think of regular system maintenance as preventive healthcare for your warehouse. It's about catching small problems before they become major disruptions. This includes scheduled equipment maintenance, regular software updates, and periodic process audits. Neglecting these small tasks can have big consequences. I saw one warehouse suffer a major system failure because their WMS software hadn't been updated in over a year. A simple update could have prevented the costly downtime.

Scaling Improvements as Your Operation Grows

As your business grows, your processes need to scale with it. This requires planning and a proactive approach. One warehouse I worked with successfully scaled its improvements with a modular approach to automation. They started with a small pilot project, then gradually expanded their automation as needed. This managed costs and minimized disruption during scaling. By implementing these strategies, you can go beyond short-term gains and create a consistently efficient warehouse, ready for any challenge.

Your Practical Implementation Roadmap

Optimizing your warehouse isn't like flipping a switch. It's more of a journey. Think of this roadmap as your trip planner, helping you prioritize improvements based on impact and how easy they are to put in place. Just like a cross-country road trip, you wouldn't just jump in the car without a plan, right?

Prioritizing for Maximum Impact

Don’t try to boil the ocean. Focus on the areas where you can get the biggest bang for your buck and implement quickly. Maybe it's something simple like reorganizing your high-traffic picking zones for a quick win. Or perhaps integrating a basic automation tool for low-stock alerts is a smarter first step. Small victories build momentum and keep the team energized.

Realistic Timelines and Budget Planning

Let’s be real - implementing a full Warehouse Management System (WMS) takes a lot longer than rearranging a storage area. Build a timeline with clear milestones so your team stays focused and feels a sense of accomplishment along the way. And don’t forget the budget! Account for the obvious costs (like software licenses) and the hidden ones, like training. Those can really sneak up on you.

Milestones and Motivation: Staying on Track

Change can be tough. Everyone likes to see progress. Setting clear metrics and celebrating milestones can really make a difference. Did you reduce average picking time by 10%? That’s awesome! Acknowledge it. Reward the team. This helps maintain momentum and keeps everyone focused on the bigger picture.

Communication and Support: Building Buy-In

Keep everyone in the loop. Regular communication about progress, including both the good and the bad, builds trust and reinforces the value of your work. When stakeholders see real, tangible results, they’re much more likely to support continued investment in improvement initiatives. Transparency is key.

Need Help? Don’t Go It Alone

Sometimes, even the best of us need a little help. Knowing when to call in the experts is a sign of strength, not weakness. If you’re hitting roadblocks with complex integrations or need help building specialized automation workflows with tools like Zapier or Make.com, think about partnering with a consultancy like Flow Genius. They specialize in building custom automation solutions tailored to your specific warehouse needs. They’ve been there, done that, and can help you navigate the complexities of automation and ensure you maximize your ROI.

Comments