10 Key Business Process Improvement Techniques for 2025

- Matthew Amann

- Jul 9, 2025

- 16 min read

In today's competitive market, standing still means falling behind. Manual tasks, outdated workflows, and inefficient systems don't just slow you down; they actively drain resources, frustrate employees, and limit your potential for growth. The key to unlocking scalable success lies in strategic, intentional optimization. If your teams in logistics, tech, or even commercial cleaning are bogged down by repetitive work, it's time to implement a structured framework for improvement.

This guide moves beyond generic advice to provide a deep dive into 10 proven business process improvement techniques, from Lean Management to Design Thinking. We will break down each methodology with actionable steps, practical examples, and specific tool recommendations to help you transform your operations. Whether you are a roofing contractor managing projects or a business broker automating outreach, these frameworks offer a clear path to reducing waste, enhancing quality, and building a more resilient organization.

To truly rethink efficiency, exploring practical business process automation examples can provide immediate, actionable insights. For those ready to turn these powerful concepts into tangible realities, this article provides the blueprint. You'll learn how to systematically identify bottlenecks and implement solutions, freeing up your team to focus on what truly matters: innovation and growth.

1. Lean Management

Lean management is a systematic business process improvement technique focused on maximizing customer value while minimizing waste. Originating from the Toyota Production System, this methodology relentlessly pursues the elimination of any activity, resource, or process step that doesn't add value for the end customer. By doing so, organizations can produce higher quality products and services more efficiently, using fewer resources and less time.

A core principle of Lean is kaizen, or continuous improvement. This isn't a one-time project but a cultural shift where every employee, especially those on the front lines, is empowered to identify and eliminate waste. For example, Toyota achieved near-perfect quality rates by embedding Lean into its culture, while Nike successfully cut supply chain lead times by 40% using these same principles.

How to Implement Lean Management

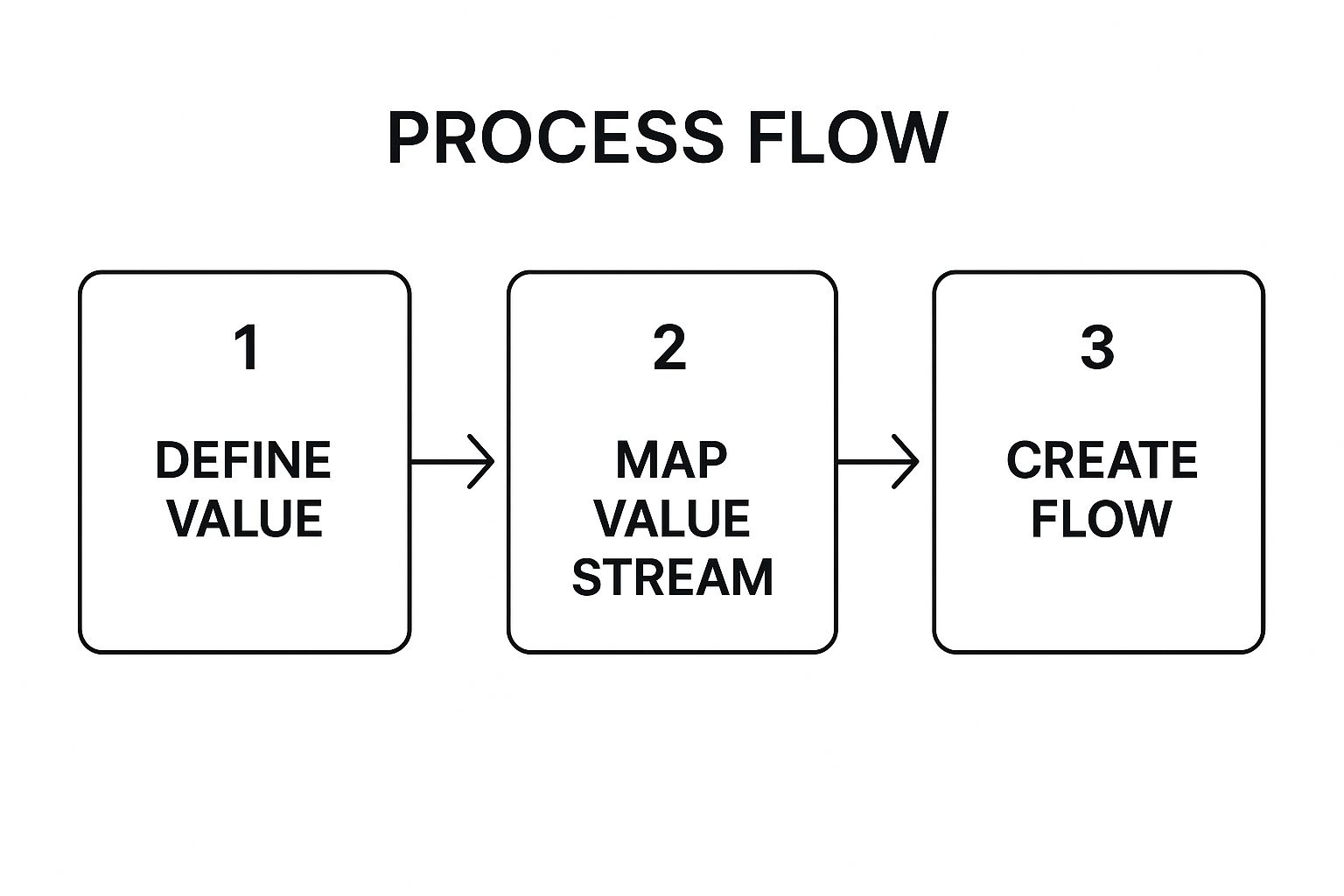

To begin, teams must first understand what the customer values and then analyze the entire process, known as the value stream, that delivers it. The following infographic outlines the initial, foundational steps for applying Lean.

This process flow visualizes the critical sequence for starting a Lean initiative, ensuring that all improvement efforts are aligned with customer expectations and process reality from the outset.

Actionable Tips for Success

Start with Value Stream Mapping: Before making changes, map your current process from start to finish to visually identify bottlenecks, delays, and non-value-added steps.

Focus on One Process: Avoid overwhelming your organization. Select a single, high-impact process for your initial implementation to build momentum and demonstrate value.

Use Visual Management: Implement tools like Kanban boards to make workflows, progress, and problems visible to the entire team, fostering accountability and quick responses.

2. Six Sigma

Six Sigma is a highly disciplined, data-driven business process improvement technique aimed at achieving near-perfect quality by eliminating defects. Developed by Motorola engineer Bill Smith, it uses statistical methods to identify and remove the causes of errors in manufacturing and business processes. The ultimate goal is to limit defects to no more than 3.4 per million opportunities, resulting in streamlined operations, increased customer satisfaction, and significant cost savings.

The methodology's power is evident in its real-world impact. General Electric famously saved over $12 billion in five years under CEO Jack Welch's advocacy, while Motorola itself reduced manufacturing defects by an astonishing 99.7%. This approach isn't limited to manufacturing; Bank of America successfully used Six Sigma to cut its loan processing time by 25%, demonstrating its versatility.

How to Implement Six Sigma

Six Sigma implementation typically follows a structured project-based framework, most commonly DMAIC (Define, Measure, Analyze, Improve, Control). This five-phase approach provides a roadmap for solving problems and improving process performance.

The DMAIC cycle ensures that solutions are based on hard data, not assumptions. This systematic process guides teams from defining a problem from the customer's perspective all the way through to implementing and sustaining the improvements, making it a robust framework for complex challenges.

Actionable Tips for Success

Secure Leadership Sponsorship: Strong, visible support from leadership is critical for providing resources, removing obstacles, and driving cultural adoption.

Invest in Proper Training: Ensure team members are properly trained and certified in Six Sigma methodologies (e.g., Green Belt, Black Belt) to effectively lead projects and analyze data.

Start with Customer-Critical Processes: Focus initial efforts on processes that have the biggest impact on customer satisfaction and business outcomes to demonstrate clear value early on.

3. Business Process Reengineering (BPR)

Business Process Reengineering (BPR) is a radical business process improvement technique that focuses on redesigning core business processes from the ground up to achieve dramatic improvements in critical performance metrics. Unlike incremental improvement, BPR challenges fundamental assumptions, often leading to a complete overhaul of how work is done, supported by technology and strategic vision. The goal isn't just to enhance existing processes but to reinvent them for a new level of efficiency and effectiveness.

This approach is best suited for situations where marginal improvements are insufficient. For instance, Ford famously used BPR to reengineer its accounts payable process, reducing headcount by 75% by eliminating the need to match purchase orders with invoices. Similarly, IBM Credit Corporation slashed its credit approval turnaround from six days to just four hours by redesigning the entire workflow around a single, empowered case manager. These examples highlight BPR's power to deliver transformative results rather than small gains.

How to Implement Business Process Reengineering

BPR begins with identifying which processes are broken or have the greatest potential for dramatic improvement. This is not about tweaking but about fundamentally rethinking the "why" and "how." It requires a clean slate approach, often enabled by technology, to design a process that meets ambitious business goals.

The implementation is a high-stakes initiative that demands strong leadership and a clear vision. It involves mapping the desired future state, designing the new process, and then building the organizational structure, roles, and systems needed to support it. This often necessitates significant change management to guide the organization through the transition.

Actionable Tips for Success

Secure Strong Top Management Commitment: BPR requires significant resources and challenges the status quo. Without unwavering support from senior leadership, the initiative is likely to fail.

Start with High-Impact Processes: Focus on core processes that are critical to customer value or have a major impact on costs and performance to demonstrate significant, visible results.

Utilize Cross-Functional Teams: Assemble teams with members from different departments to ensure the redesigned process is holistic, breaks down organizational silos, and considers all stakeholder needs.

4. Kaizen

Kaizen is a Japanese business philosophy centered on the principle of continuous, incremental improvement. Rather than pursuing large, disruptive changes, this business process improvement technique advocates for making small, ongoing positive changes. Its power lies in accumulating these minor adjustments over time to generate significant long-term results in productivity, efficiency, and quality.

The core of Kaizen is its inclusive, bottom-up approach, where every employee, from the CEO to frontline workers, is encouraged to identify and suggest improvements. Toyota famously built its world-class manufacturing system on this principle, receiving millions of employee ideas annually. Similarly, Canon leveraged Kaizen to reduce equipment setup times by a remarkable 98%, demonstrating the profound impact of consistent, small-scale enhancements.

How to Implement Kaizen

Implementing Kaizen begins with fostering a culture that views problems as opportunities for improvement rather than mistakes to be punished. The focus is on creating a supportive environment where teams feel empowered to experiment and refine their daily work. For a practical application of these principles within specific business areas, consider insights on solving customer support problems with lessons from Kaizen in problem-solving.

Actionable Tips for Success

Start with Small, Achievable Improvements: Encourage teams to identify and implement low-cost, low-risk changes first to build momentum and demonstrate the value of the process.

Create Suggestion Systems: Establish formal channels, like suggestion boxes or digital platforms, where employees can easily submit their ideas for process improvements.

Hold Regular Kaizen Events: Organize focused workshops (often called Kaizen blitzes) where cross-functional teams collaborate to solve a specific problem in a short, intensive period.

Standardize Successful Improvements: Once a change proves effective, document it and make it the new standard operating procedure to lock in the gains and provide a baseline for future improvements.

5. Agile Methodology

Agile methodology is a business process improvement technique that prioritizes flexibility, customer collaboration, and rapid, iterative progress. Originally created for software development, its principles are now widely applied across various industries to manage complex projects and respond swiftly to change. Instead of following a rigid, long-term plan, Agile breaks down large projects into small, manageable increments called "sprints."

This iterative approach enables teams to deliver value quickly and adapt based on continuous feedback. For instance, ING Bank's agile transformation reduced its time-to-market by over 20%, while Hasbro used agile to cut its toy development cycle time in half. These successes highlight how Agile fosters an environment of continuous improvement and customer-centric delivery. This methodology is often a key component of a successful business evolution, and you can learn more about its role in digital transformation and how to apply it effectively.

How to Implement Agile Methodology

Implementation begins by shifting the team's mindset from delivering a final product to delivering incremental value. This involves creating a backlog of tasks, prioritizing them based on customer needs, and executing them in short sprints, typically lasting one to four weeks. Frameworks like Scrum or Kanban provide the structure for managing this workflow, with daily stand-up meetings to align the team and sprint retrospectives to refine the process.

Actionable Tips for Success

Start with Pilot Projects: Select a small, well-defined project to test agile principles. This helps your team learn the process and demonstrate its value without disrupting the entire organization.

Invest in Training: Proper training on agile frameworks like Scrum is essential. Ensure every team member understands their role, the ceremonies involved, and the core values of transparency and adaptation.

Embrace Change: A core tenet of Agile is responding to change over following a plan. Encourage teams to be flexible and prepared to pivot based on new insights or customer feedback.

6. Total Quality Management (TQM)

Total Quality Management (TQM) is a comprehensive business process improvement technique where quality is ingrained into every organizational function. It’s a management philosophy dedicated to continuous improvement by involving all employees, from top leadership to the front lines, in the pursuit of customer satisfaction. The core idea is that quality isn't just a final inspection; it's the responsibility of everyone involved in creating and delivering a product or service.

TQM is a cultural commitment to excellence. For example, Xerox revived its market share by implementing TQM, which led to winning the prestigious Malcolm Baldrige National Quality Award. Similarly, Florida Power & Light became the first non-Japanese company to win the Deming Prize by deeply embedding TQM principles into its operations, proving its universal effectiveness. This approach drives long-term success by making quality a strategic imperative.

How to Implement Total Quality Management (TQM)

Implementing TQM requires a top-down, organization-wide commitment. The process begins with establishing a customer-focused culture and empowering employees to take ownership of quality. Management must lead by example, providing the necessary training, resources, and support to foster an environment of continuous improvement and proactive problem-solving. It's a fundamental shift from detecting defects to preventing them in the first place.

This strategy ensures that every department works cohesively toward shared quality goals. By integrating customer feedback and systematically analyzing processes, organizations can consistently enhance value and performance across the board.

Actionable Tips for Success

Secure Strong Leadership Commitment: TQM cannot succeed as a grassroots effort alone. Executive leadership must champion the initiative, allocate resources, and model the desired quality-focused behaviors.

Implement Comprehensive Training: Equip all employees with knowledge of TQM principles, problem-solving tools, and statistical process control. Training ensures everyone speaks the same quality language.

Establish Customer Feedback Systems: Create robust channels to collect, analyze, and act on customer feedback. This data is critical for aligning improvement efforts with what customers truly value.

7. Value Stream Mapping (VSM)

Value Stream Mapping (VSM) is a powerful business process improvement technique that provides a visual representation of every step in a production or service delivery process. More than a simple flowchart, VSM documents the flow of both materials and information required to bring a product or service from its beginning to the end customer. Its primary goal is to illuminate sources of waste and identify bottlenecks, making it a cornerstone of Lean methodology.

By analyzing the entire value stream, organizations can pinpoint non-value-added activities and redesign their processes for optimal efficiency. For instance, Ford famously used VSM to reduce its vehicle assembly lead time by 25%, while Seattle Children's Hospital cut patient discharge times by a remarkable 43%. These examples highlight VSM's effectiveness in complex environments, making it one of the most impactful business process improvement techniques available.

How to Implement Value Stream Mapping

The VSM process begins by creating a "current state" map that details the process as it exists today. This map includes critical data points like cycle times, inventory levels, and wait times. Once the current state is understood, the team develops a "future state" map that visualizes a leaner, more efficient process. For those new to this technique, understanding the fundamentals of creating a process map is a crucial first step. Learn more about creating process maps to improve your workflows.

Actionable Tips for Success

Walk the Actual Process: Don't create your map from a conference room. Physically walk the path of the value stream (the gemba) to observe the work, ask questions, and gather real-time data.

Involve a Cross-Functional Team: Include people who actually perform the work, from frontline operators to managers and support staff. Their direct insights are invaluable for an accurate map.

Focus on Flow, Not Just Steps: VSM's unique power comes from analyzing the flow between steps. Pay close attention to handoffs, delays, and information transfers, as this is where most waste is found.

8. Business Process Management (BPM)

Business Process Management (BPM) is a holistic and systematic business process improvement technique that uses methods, tools, and technology to continuously discover, model, analyze, measure, improve, and automate business workflows. Unlike a one-off project, BPM is a continuous discipline focused on aligning all aspects of an organization with the wants and needs of clients. It treats processes as strategic assets that must be understood, managed, and optimized to deliver value.

The goal of BPM is to make an organization's workflow more effective, efficient, and adaptable to an ever-changing environment. For example, insurance giant Allianz used BPM to reduce its claims processing time by a remarkable 70%. Similarly, T-Mobile leveraged BPM principles to improve its customer onboarding process by 50%, demonstrating its power to enhance both internal efficiency and customer experience.

How to Implement Business Process Management

Implementing BPM involves a cyclical lifecycle of modeling, execution, monitoring, and optimization. This approach ensures that processes are not just improved once but are continuously refined over time. A critical component of effective Business Process Management (BPM) is leveraging tools like sales process automation to streamline workflows and drive revenue. This automation frees up teams to focus on higher-value activities while ensuring consistency and accuracy in routine tasks.

Actionable Tips for Success

Start with High-Impact Processes: Begin your BPM initiative by focusing on high-volume, rule-based processes where the potential for improvement and ROI is greatest.

Model Before You Automate: Always create a detailed process model (e.g., using BPMN) to understand the "as-is" state and design the "to-be" state before investing in automation technology.

Invest in Change Management: Successful BPM requires a cultural shift. Ensure you provide comprehensive user training and clear communication to get buy-in from all stakeholders.

Monitor Performance Continuously: Use BPM software to track key performance indicators (KPIs) in real-time, allowing you to quickly identify bottlenecks and opportunities for further optimization. Learn more about the fundamentals of business process automation.

9. Root Cause Analysis (RCA)

Root Cause Analysis (RCA) is a systematic business process improvement technique used to identify the true, underlying causes of a problem rather than just treating its symptoms. The goal is to drill down past superficial issues to find the fundamental reason an incident occurred, allowing organizations to implement corrective actions that prevent recurrence. By focusing on the source, RCA ensures that solutions are permanent and effective, not just temporary fixes.

This problem-solving method is crucial in high-stakes industries where preventing failure is paramount. For example, NASA famously used RCA to investigate space shuttle accidents, leading to systemic changes that prevented future disasters. Similarly, healthcare organizations apply RCA to understand and prevent critical medical errors, moving beyond individual blame to improve patient safety systems.

How to Implement Root Cause Analysis

The process begins with a clear and concise definition of the problem. From there, a team investigates the issue by asking progressively deeper questions to trace the chain of cause and effect back to its origin. Common tools like the "5 Whys" or the Fishbone (Ishikawa) diagram help structure this investigation, ensuring no potential cause is overlooked.

Once the root cause is identified, the focus shifts to developing and implementing robust corrective actions. These actions are designed to eliminate the fundamental issue, followed by a verification process to confirm the solution has effectively resolved the problem and prevented its return.

Actionable Tips for Success

Define the Problem Clearly: Before starting, create an unambiguous problem statement that specifies what happened, where, when, and its impact. A vague starting point leads to an unfocused analysis.

Use Multiple RCA Techniques: For complex issues, combine methods. Use a Fishbone diagram to brainstorm potential causes and then apply the "5 Whys" to dig deeper into the most likely contributors.

Focus on System Issues: Direct the investigation toward breakdowns in processes, systems, or training rather than blaming individuals. This creates a safe environment for honest participation and reveals more meaningful opportunities for improvement.

10. Design Thinking

Design Thinking is a human-centered business process improvement technique that focuses on understanding the end-user's needs to solve complex problems. Popularized by firms like IDEO and the Stanford d.school, it integrates empathy, creativity, and analytical thinking to create innovative solutions that are not only functional but also desirable. This methodology moves beyond traditional problem-solving by placing the human experience at the core of the process.

The power of Design Thinking lies in its ability to uncover unarticulated needs. For instance, Bank of America used this approach to develop its "Keep the Change" savings program after observing how customers struggled with saving money. Similarly, Airbnb revitalized its struggling business by using empathy-driven photography to better represent hosts' spaces, directly addressing user uncertainty and building trust.

How to Implement Design Thinking

The process is iterative and non-linear, typically following five key phases: Empathize, Define, Ideate, Prototype, and Test. It encourages teams to challenge assumptions and redefine problems, creating a framework for continuous innovation and improvement. The goal is to gain a deep understanding of the user before generating solutions.

Actionable Tips for Success

Build Empathy First: Begin with deep user research. Conduct interviews, create user personas, and map empathy journeys to truly understand your audience's pains and gains.

Encourage Wild Ideas: During ideation, focus on quantity over quality. Use brainstorming techniques that defer judgment to generate a broad range of creative solutions.

Prototype Rapidly: Create low-cost, low-fidelity prototypes like sketches or simple mockups. This allows you to test concepts quickly and gather feedback without investing significant resources.

Form Diverse Teams: Assemble cross-functional teams with varied perspectives (e.g., engineering, marketing, design, customer service) to foster more holistic and innovative solutions.

Business Process Improvement Techniques Comparison

Methodology | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Lean Management | Moderate; requires cultural change and ongoing discipline | Moderate; involves employee training and visual tools | Waste reduction, improved quality, shorter lead times | Continuous process improvement, manufacturing, service efficiency | Cost reduction, employee engagement, operational efficiency |

Six Sigma | High; requires extensive training and certification | High; needs statistical tools and expert staff | Significant defect reduction, data-driven decisions | Quality improvement in critical, stable processes | Near-perfect quality, structured problem-solving |

Business Process Reengineering (BPR) | Very high; involves radical redesign and change management | High; substantial investment and cross-functional teams | Dramatic performance improvements, cost and time reduction | Fundamental process overhauls, breakthrough performance | Breakthrough improvements, competitive advantage |

Kaizen | Low to moderate; continuous small changes | Low; utilizes employee ideas and minimal tools | Incremental but sustainable improvements | Cultures focused on gradual improvement and employee engagement | Low risk, strong employee involvement, sustainable culture |

Agile Methodology | Moderate to high; requires cultural shift and skilled teams | Moderate; investment in training and collaboration tools | Faster delivery, adaptability, improved customer feedback | Software development, projects with changing requirements | Rapid time-to-market, flexibility, enhanced collaboration |

Total Quality Management (TQM) | High; organization-wide cultural transformation needed | High; extensive training and systematic quality efforts | Long-term quality improvements, customer satisfaction | Organization-wide quality culture development | Holistic quality focus, cost reduction, enhanced morale |

Value Stream Mapping (VSM) | Low to moderate; requires training on mapping techniques | Low to moderate; mainly time and team involvement | Clear process visualization, waste identification | Identifying process inefficiencies and improvement prioritization | Visual clarity, waste identification, team alignment |

Business Process Management (BPM) | High; technical complexity and ongoing maintenance | High; needs software tools, technical experts | Process automation, adaptability, cost reduction | Workflow optimization in complex organizations | Automation, end-to-end visibility, compliance |

Root Cause Analysis (RCA) | Moderate; requires analytical skills and quality data | Moderate; skilled facilitators and investigation time | Problem prevention, improved reliability | Problem solving for recurring or critical issues | Prevents recurrence, builds organizational knowledge |

Design Thinking | Moderate; requires cultural shift toward experimentation | Moderate; needs multidisciplinary teams and prototyping resources | Innovative solutions, improved user experience | Innovation, user-centered product/service design | Creativity, risk reduction via early testing, user focus |

From Theory to Action: Implementing Your Improvement Strategy

You’ve explored a comprehensive toolkit of ten powerful business process improvement techniques, from the waste-eliminating principles of Lean Management to the radical transformation of Business Process Reengineering (BPR). We've delved into the statistical rigor of Six Sigma, the continuous, incremental gains of Kaizen, and the customer-centric innovation of Design Thinking. Each method offers a unique lens through which to view and refine your operations, providing a structured path from inefficiency to excellence.

The journey doesn't end with understanding these frameworks. True competitive advantage is forged in their application. The key takeaway is that there is no one-size-fits-all solution; the most successful organizations skillfully blend these methodologies to create a custom-fit strategy. A technology company might fuse Agile sprints with Design Thinking to accelerate product development, while a logistics director could use Value Stream Mapping to identify bottlenecks before applying Lean principles to streamline their supply chain.

Turning Knowledge into Tangible Results

The critical next step is to move from passive learning to active implementation. Don't let this wealth of information remain theoretical. The path forward involves a clear, deliberate sequence of actions designed to build momentum and deliver measurable wins.

To begin your transformation, follow these actionable steps:

Select a Pilot Process: Instead of attempting a company-wide overhaul, choose a single, high-impact process. Focus on an area that is a known source of frustration, cost overruns, or customer complaints. This could be anything from your client onboarding workflow to inventory management or even your outbound sales outreach.

Diagnose and Document: Use a diagnostic tool like Root Cause Analysis (RCA) or Value Stream Mapping (VSM) to gain an objective, data-backed understanding of the current state. Map every step, identify every delay, and quantify the waste. This crucial step moves you from assumption to evidence-based analysis.

Choose Your Framework: With a clear diagnosis, select the appropriate improvement framework. Is the problem a need for incremental, continuous improvement? Kaizen is your ally. Does the process require a fundamental redesign from the ground up? BPR provides the blueprint. Are you battling defects and quality variance? Six Sigma offers the statistical tools you need.

The Automation Catalyst: Amplifying Your Efforts

Mastering these business process improvement techniques sets the foundation for a more efficient, agile, and resilient organization. However, in today's digital landscape, the ultimate accelerator for these methodologies is automation. Manually implementing changes can still leave your team burdened with repetitive, time-consuming tasks. Automation is what truly unlocks the potential of a redesigned process.

By integrating tools like Zapier, Make.com, or custom API scripts, you can put your optimized workflows on autopilot. Imagine your CRM automatically updating after a client call, your scheduling software seamlessly coordinating with your supply inventory, or your outbound email sequences triggering based on specific customer actions. This is where the theoretical benefits of process improvement become a tangible, everyday reality, freeing your team to focus on strategic, high-value work that drives growth.

Ready to supercharge your business process improvement with expert automation? Let Flow Genius design and implement the custom workflows that turn your strategic plans into reality. Visit Flow Genius to discover how we can help you build a more efficient, automated, and profitable business.