7 Key Operational Efficiency Metrics to Track in 2025

- Matthew Amann

- Aug 1, 2025

- 15 min read

In today's competitive landscape, the line between activity and achievement is finer than ever. Busy teams don't always equal productive operations. The real measure of success lies in how effectively you convert resources-time, money, and manpower-into value. This is the essence of operational efficiency, and understanding it is the first step toward unlocking your business's true potential. But how do you measure it? The answer lies in tracking the right operational efficiency metrics.

These aren't just abstract numbers; they are the diagnostic tools that reveal the health of your business. They pinpoint bottlenecks, waste, and hidden opportunities for growth across every department. Improving these areas often involves a holistic view of your processes, from workflow automation to resource management. For instance, optimizing your facility's power consumption is a key component, making it important to understand trends in industrial energy efficiency in 2025.

This guide demystifies the seven most impactful operational efficiency metrics that leading companies use to gain a competitive edge. We will define each one, show you exactly how to calculate it, and provide real-world examples to help you implement them effectively and drive meaningful change.

1. Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness (OEE) stands as a gold standard among operational efficiency metrics, particularly within manufacturing and asset-intensive industries. It measures the percentage of planned production time that is genuinely productive. OEE isn’t just about running equipment; it’s about running it well, quickly, and with minimal defects.

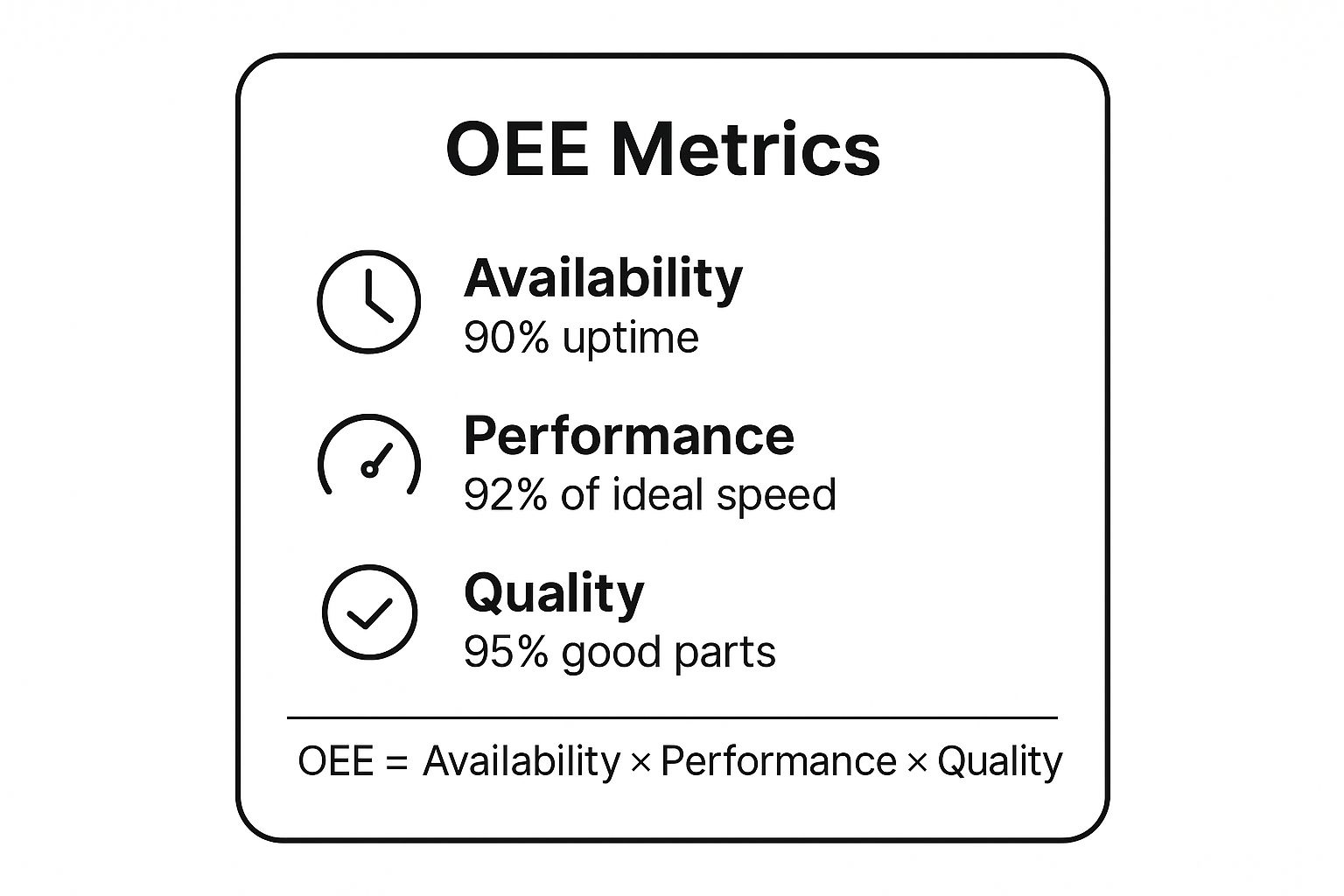

The power of OEE lies in its composite formula, which synthesizes three critical operational factors into a single, comprehensive score:

Availability: Accounts for any downtime, including unplanned stops (like equipment failure) and planned stops (like changeovers).

Performance: Considers any factors that cause the equipment to operate at less than its maximum possible speed, such as slow cycles or minor stops.

Quality: Factors in defective parts, including those that need to be reworked. The goal is to measure the percentage of good parts produced.

The final OEE score provides a clear, holistic benchmark for identifying losses, tracking improvements, and enhancing equipment productivity.

Calculation and Implementation

Calculating OEE is straightforward: Availability × Performance × Quality = OEE Score. An OEE score of 100% signifies perfect production: manufacturing only good parts, as fast as possible, with no stop time. While 100% is the ideal, a world-class score is typically considered 85% or higher.

The infographic below visualizes how these three components contribute to the final OEE score, showing a high-performing but not-quite-perfect scenario.

As the data shows, even with high individual scores, the cumulative effect results in an OEE of just 76.14% (0.90 × 0.92 × 0.95), highlighting how small inefficiencies can compound.

Actionable Tips for Using OEE

To effectively leverage OEE, start small. Focus on a single pilot machine to refine your data collection and analysis process before a company-wide rollout. Ensure data integrity by using automated sensors and machine logs rather than manual tracking, which is prone to error.

Key Insight: The true value of OEE comes from analyzing the six big losses that cause its score to drop: equipment failure, setup and adjustments, idling and minor stops, reduced speed, process defects, and reduced yield. By tackling the largest loss category first, teams can make the most significant impact on operational efficiency.

For businesses looking to integrate such key performance indicators into their workflows, it’s beneficial to explore a broader framework. You can learn more about how OEE fits into a larger strategy by checking out this guide to operational performance indicators. This metric is a cornerstone for any operation, from technology companies automating software to logistics directors optimizing supply chains, providing a clear path to reduced waste and increased output.

2. First Pass Yield (FPY)

First Pass Yield (FPY) is a fundamental quality-focused metric used to evaluate process efficiency. It measures the percentage of products or services that are completed to specification on the first attempt, without needing any rework, repair, or being scrapped entirely. As one of the core operational efficiency metrics, FPY provides a clear, immediate signal of process health and identifies hidden costs associated with poor quality.

The significance of FPY, championed by quality pioneers like W. Edwards Deming and central to Six Sigma methodologies, lies in its direct link to waste reduction. A low FPY indicates that time, materials, and labor are being consumed correcting errors rather than creating value. High-profile companies like Boeing use FPY to minimize costly rework in complex aircraft assembly, while Samsung applies it rigorously in semiconductor manufacturing where initial quality is paramount.

Calculation and Implementation

The formula for FPY is direct and insightful: (Number of Units Passing First Time / Total Number of Units Entering the Process) × 100% = FPY. An FPY of 100% means every unit produced meets quality standards without any intervention. Even a seemingly high FPY of 95% indicates that 5 out of every 100 units require costly additional handling.

For instance, if a software development team pushes 20 new features and 2 of them require immediate hotfixes due to bugs found in production, the FPY is 90% (18 / 20). This metric immediately quantifies the initial quality of the development cycle. For more complex, multi-step processes, Rolled Throughput Yield (RTY) can be used, which multiplies the FPY of each individual step to provide an end-to-end quality view.

Actionable Tips for Using FPY

To improve FPY, the focus must be on proactive quality assurance, not just reactive inspection. Start by implementing robust quality control systems at critical process points to catch deviations early. This includes providing comprehensive operator training on quality standards and work instructions to ensure consistency.

Using statistical process control (SPC) charts can help teams visualize process stability and identify when a process is drifting out of its specified limits before defects occur. This allows for data-driven adjustments rather than guesswork.

Key Insight: A low FPY is a symptom, not the disease. The most effective improvements come from performing root cause analysis (RCA) on failures. Instead of just fixing a defective part, ask "why" it was defective in the first place. Addressing the root cause, such as an out-of-calibration machine or inadequate material specification, prevents future occurrences and drives sustainable FPY improvement.

3. Cycle Time

Cycle Time is one of the most fundamental operational efficiency metrics, essential for understanding process speed and capacity. It measures the total elapsed time required to complete one unit of a process from its designated start point to its finish point. Popularized by the Toyota Production System and lean manufacturing, Cycle Time provides a direct measure of how quickly a system can produce a single item, whether it's assembling a car, processing an invoice, or resolving a customer support ticket.

The power of this metric lies in its comprehensive nature. It captures every moment of the process, including:

Value-Added Time: The actual time spent actively working on the product or service.

Non-Value-Added Time: The time spent waiting, such as delays, queues, and handoffs between steps.

By analyzing the entire duration, teams can pinpoint bottlenecks and inefficiencies that bloat production timelines, making it a critical KPI for capacity planning and process improvement. A shorter cycle time directly translates to increased throughput, faster delivery to customers, and a more agile operation.

Calculation and Implementation

Calculating Cycle Time is conceptually simple: Cycle Time = Process End Time – Process Start Time. The key is to clearly and consistently define the start and end points of the process you are measuring. For instance, in manufacturing, this could be from the moment raw materials enter the production line until the finished product is packaged.

Southwest Airlines famously optimized its aircraft turnaround cycle time to as little as 25 minutes, a feat that allows them to maximize flight schedules and asset utilization. Similarly, Dell's revolutionary build-to-order model was built on minimizing manufacturing cycle time, enabling them to deliver customized PCs far faster than competitors. These examples show how a focus on reducing cycle time can become a powerful competitive advantage.

Actionable Tips for Using Cycle Time

To make Cycle Time a truly transformative metric, begin by meticulously mapping your entire process to identify every individual step. This visual map helps ensure you measure from consistent start and end points and provides a clear framework for analysis. Differentiate between value-added activities and non-value-added time, as the latter is often the primary target for elimination.

Key Insight: The greatest improvements in Cycle Time often come from attacking the non-value-added time. Focus on reducing wait times, streamlining handoffs, and eliminating unnecessary process steps. Automating manual transfers or approvals can drastically cut down on queue time, which frequently accounts for the largest portion of the total cycle.

For any business aiming to enhance its responsiveness, from e-commerce giants like Amazon reducing order-to-delivery times to software firms accelerating feature development, mastering Cycle Time is non-negotiable. It provides a clear, quantifiable path to boosting productivity and customer satisfaction.

4. Throughput

Throughput is one of the most fundamental operational efficiency metrics, measuring the rate at which a system generates its products or services over a specific period. Popularized by Eliyahu M. Goldratt in his "Theory of Constraints," this metric represents the actual output of a process, department, or entire organization, often expressed as units per hour, day, or week. It directly reflects how effectively a system converts inputs into sellable outputs.

The significance of throughput lies in its direct link to revenue generation. Unlike measures that focus on cost reduction, throughput quantifies the speed of value creation. It forces businesses to identify and manage their primary constraint or bottleneck, as the system's overall throughput can never exceed the capacity of its slowest part.

McDonald's: Optimized its kitchen workflow, enabling it to serve millions of customers daily by maximizing burger assembly and delivery throughput.

TSMC: A leading semiconductor manufacturer, meticulously tracks wafer throughput (the number of silicon wafers processed per hour) as a core measure of fab productivity.

UPS: Engineered its sorting facilities, like the Worldport hub, to achieve a staggering throughput of over 400,000 packages per hour, a key to its global logistics dominance.

Calculation and Implementation

Calculating throughput is conceptually simple: Total Units Produced / Time Period = Throughput Rate. For instance, if a production line creates 4,000 finished goods in an 8-hour shift, its throughput is 500 units per hour. The challenge lies in accurately defining "units" and consistently measuring time.

Implementation requires a systemic view. Instead of optimizing individual machines in isolation, the focus shifts to the system's single biggest constraint. Improving any non-bottleneck part of the process will not increase overall throughput and may even create excess work-in-progress inventory. The goal is to subordinate all other processes to the speed of the bottleneck.

Actionable Tips for Using Throughput

To effectively use throughput as a metric, focus on the system's flow. Start by identifying the primary bottleneck that limits your output and concentrate all improvement efforts there. This ensures your resources generate the highest possible return.

Balance throughput with quality; increasing speed at the expense of creating defects is counterproductive. Use statistical process control (SPC) to monitor both output and quality simultaneously, ensuring that gains in speed are not nullified by rework or waste.

Key Insight: The Theory of Constraints provides a powerful five-step focusing process for managing throughput: Identify the constraint, exploit the constraint, subordinate everything else to the constraint, elevate the constraint, and repeat the process. This cycle ensures continuous improvement is always directed at the point of maximum leverage, preventing wasted effort on non-critical optimizations.

This metric is vital across industries. For technology companies, it could measure features deployed per sprint. For logistics directors, it's packages shipped per day. By mastering throughput, any organization can directly accelerate its ability to generate revenue and satisfy customer demand.

5. Resource Utilization Rate

The Resource Utilization Rate is one of the most fundamental operational efficiency metrics, measuring the percentage of time that a resource is actively engaged in productive work compared to its total available time. This versatile metric applies to people, equipment, facilities, or any other critical asset, helping organizations understand how effectively they are deploying their capital and labor to generate value.

The power of this metric lies in its simplicity and breadth. It provides a clear view into capacity management, highlighting whether resources are over-burdened or under-utilized. For example, a hospital might track operating room utilization (where the industry average is 65-70%), while a ride-sharing service like Uber optimizes driver utilization to balance supply with rider demand.

Human Resources: Measures the billable or productive hours of employees against their total paid hours.

Equipment: Tracks the active operational time of machinery or vehicles versus their total available time.

Facilities: Assesses the occupancy or usage of spaces like conference rooms, warehouses, or hospital beds.

A high utilization rate often correlates with higher profitability, but pushing it too high can lead to burnout, breakdowns, and a lack of flexibility.

Calculation and Implementation

Calculating the Resource Utilization Rate is straightforward: (Actual Time Used / Total Time Available) × 100% = Utilization Rate. For instance, if a consultant is available for 40 hours a week and logs 32 billable hours, their utilization rate is 80%.

This calculation helps identify systemic inefficiencies. A low rate might indicate poor scheduling, insufficient demand, or workflow bottlenecks. Conversely, a rate approaching 100% could signal a need for more resources or process optimization to prevent strain. Airlines, for example, master this by achieving over 80% aircraft utilization through complex scheduling to keep expensive assets generating revenue.

Actionable Tips for Using Resource Utilization Rate

To implement this metric effectively, set distinct target utilization rates based on the resource type and strategic goals; a key piece of machinery might be targeted for 90% utilization, while a creative team might aim for 70% to allow for innovation. Always account for planned downtime, such as scheduled maintenance or training, within the "Total Time Available" to ensure your metric reflects realistic capacity.

Key Insight: The ultimate goal is not to maximize utilization but to optimize it. Balancing high utilization with the necessary flexibility to handle unexpected demands or opportunities is crucial. Over-scheduling can be just as damaging to long-term efficiency as under-utilization. Using predictive analytics can help forecast demand and plan resource allocation more effectively.

For organizations looking to refine how they allocate these critical assets, developing a sophisticated approach is key. You can discover more about balancing these factors by exploring these top resource allocation strategies for 2025 success. This metric is invaluable for any manager, from a logistics director planning fleet schedules to a tech lead managing a development team's sprint capacity.

6. Cost Per Unit

Cost Per Unit is one of the most fundamental operational efficiency metrics, offering a direct measure of the total cost required to produce a single unit of output. It provides a clear, bottom-line view of production efficiency by encapsulating all expenses, from raw materials and labor to factory overhead. For any business, from manufacturing giants to software startups, understanding this metric is crucial for pricing strategies, profitability analysis, and cost control.

The power of Cost Per Unit lies in its simplicity and its ability to expose hidden inefficiencies. It aggregates two primary cost categories into a single, digestible figure:

Variable Costs: Expenses that change in direct proportion to production volume, such as raw materials, direct labor, and production supplies.

Fixed Costs: Expenses that remain constant regardless of output, including rent, salaries of administrative staff, and equipment depreciation.

By monitoring this metric, organizations can pinpoint exactly where money is being spent and identify opportunities to optimize processes, negotiate better supplier terms, or invest in more efficient technology.

Calculation and Implementation

Calculating Cost Per Unit is straightforward: (Total Fixed Costs + Total Variable Costs) / Total Units Produced = Cost Per Unit. A lower cost per unit generally indicates higher operational efficiency, allowing for greater profit margins or more competitive pricing. For instance, Tesla famously drove its Model 3 cost per unit down from an estimated $84,000 to below $37,500 through innovations in manufacturing and supply chain management.

For businesses aiming for a detailed breakdown, it is essential to distinguish between different types of expenses. A deep understanding of the calcul du coût variable is particularly useful for separating costs that scale with production from those that are static, enabling more precise financial modeling and decision-making.

Actionable Tips for Using Cost Per Unit

To effectively leverage Cost Per Unit, start by ensuring accurate cost allocation. Using methods like activity-based costing (ABC) can provide a more precise picture than traditional accounting. Track the metric consistently over time to identify trends and measure the impact of efficiency initiatives.

Key Insight: The true value of Cost Per Unit emerges when it's used for benchmarking. Compare your figures against industry averages or direct competitors to understand your competitive position. Southwest Airlines, for example, mastered this by achieving the lowest cost per available seat mile, which became a cornerstone of its disruptive, low-fare business model.

For businesses looking to implement changes based on this metric, a focused strategy is key. You can discover effective methods by reading this guide on proven strategies to reduce operating costs. This metric is not just for manufacturers; it's a vital tool for any operation looking to maximize profitability and deliver value.

7. On-Time Delivery (OTD)

On-Time Delivery (OTD) is a cornerstone among operational efficiency metrics, especially for businesses in logistics, e-commerce, and service industries. It measures the percentage of orders delivered to customers by the promised or scheduled date. OTD directly reflects an organization's reliability and its ability to meet customer commitments, which is a critical driver of satisfaction, loyalty, and competitive advantage.

The strength of OTD lies in its customer-centric focus. While internal metrics optimize processes, OTD evaluates the final outcome from the customer's perspective. It synthesizes the performance of the entire supply chain, from order processing and inventory management to fulfillment and final-mile logistics.

Order Processing: How quickly and accurately an order is received and entered into the system.

Fulfillment: The time it takes to pick, pack, and prepare an order for shipment.

Transit: The performance of shipping carriers and logistics partners in moving the product to its destination.

A high OTD rate signals a well-oiled, synchronized operation, while a low rate can quickly reveal bottlenecks in the supply chain, such as poor inventory management or unreliable shipping partners.

Calculation and Implementation

Calculating On-Time Delivery is straightforward: (Number of Orders Delivered On Time / Total Number of Orders Shipped) × 100 = OTD Rate (%). The definition of "on time" must be clear and consistent, based on the delivery date promised to the customer. While 100% is the goal, top performers like Amazon Prime and FedEx consistently achieve rates over 95%.

For example, if a company ships 5,000 orders in a month and 4,850 of them arrive by the promised date, its OTD rate is 97% (4,850 / 5,000 × 100). This simple calculation provides a powerful KPI for measuring customer-facing performance.

Actionable Tips for Using OTD

To effectively improve your OTD rate, focus on proactive management and communication. First, set realistic delivery commitments based on historical data and current capacity, not just aspirational goals. Implement robust planning systems that provide real-time visibility into inventory levels and production schedules to prevent stockouts.

Building buffer time into your delivery windows can absorb unexpected delays without impacting the customer's promised date. Finally, proactive communication is key; if a delay is unavoidable, informing the customer immediately can mitigate dissatisfaction.

Key Insight: OTD is not just a logistics metric; it’s a reflection of your entire operational promise. Analyzing the reasons for missed deliveries, whether due to internal process failures, supplier delays, or carrier issues, provides a clear roadmap for targeted improvements across the entire value chain. Start by segmenting failures to identify the root cause, allowing for focused, high-impact interventions.

Operational Efficiency Metrics Comparison

Metric | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

Overall Equipment Effectiveness (OEE) | Medium-High: Needs accurate data systems and integration | Moderate to High: Data collection devices, skilled analysts | Holistic equipment efficiency (availability × performance × quality) | Manufacturing plants, continuous improvement | Comprehensive performance view, loss identification, benchmarking |

First Pass Yield (FPY) | Low to Medium: Simple calculation, requires quality data | Low to Moderate: Quality control and inspection resources | High product quality, reduced waste and rework costs | Quality control, production processes | Easy to communicate, reduces costs, improves customer satisfaction |

Cycle Time | Medium: Requires process mapping and consistent measurement | Moderate: Measurement tools and process analysts | Shortened total process time, bottleneck identification | Capacity planning, process improvement | Identifies delays, supports resource planning, improves responsiveness |

Throughput | Low to Medium: Basic tracking of output rate | Low to Moderate: Production monitoring systems | Increased output rate, identifies bottlenecks | Production volume management, bottleneck focus | Clear productivity measure, directly impacts revenue |

Resource Utilization Rate | Medium: Requires tracking productive time vs. available time | Moderate: Time tracking systems and analytics | Better resource allocation, reduced idle time | Workforce and equipment scheduling | Identifies underutilization, improves ROI, supports planning |

Cost Per Unit | Medium: Cost accounting system setup required | Moderate to High: Accounting and data integration | Cost control, profitability insights | Pricing strategy, cost reduction efforts | Clear profitability metric, aids competitive pricing |

On-Time Delivery (OTD) | Low to Medium: Depends on delivery tracking systems | Moderate: Planning and logistics resources | Improved customer satisfaction and reliability | Supply chain, logistics, customer service | Builds trust, reduces penalties, enhances competitiveness |

From Metrics to Momentum: Turning Insights into Action

Navigating the landscape of operational efficiency can feel complex, but the seven key metrics we've explored provide a powerful and reliable compass. From the granular focus of Overall Equipment Effectiveness (OEE) and First Pass Yield (FPY) to the broader process-level insights of Cycle Time and Throughput, each metric offers a distinct, critical piece of the performance puzzle. They are not just abstract numbers; they are the vital signs of your business's health.

Understanding how to calculate Cost Per Unit or track On-Time Delivery is the foundational step. The true transformation, however, begins when you move from passive measurement to active management. These operational efficiency metrics are not meant to be recorded once and filed away. They are dynamic tools that, when monitored consistently, reveal hidden bottlenecks, highlight opportunities for innovation, and validate the success of your strategic initiatives. Think of them as a real-time feedback loop, constantly informing your next move.

Your Action Plan for Implementation

Knowledge without action is merely potential. To convert these insights into tangible results, you need a clear, structured approach. Don't try to tackle everything at once, as this can lead to overwhelm and inaction. Instead, follow a phased implementation plan.

Prioritize Your Focus: Start by selecting one or two metrics that directly address your most significant operational pain points. If project delays are hurting your reputation, begin with On-Time Delivery and Cycle Time. If profitability is a concern, focus on Cost Per Unit and Resource Utilization Rate.

Establish a Baseline: You cannot improve what you don't measure. Dedicate a specific period, perhaps a month or a quarter, to consistently track your chosen metrics without making any major changes. This initial data creates the baseline against which all future progress will be measured.

Set SMART Goals: Define what success looks like. Your goals should be Specific, Measurable, Achievable, Relevant, and Time-bound. For instance, a goal could be "Reduce average cycle time for roofing projects by 15% within the next six months."

Automate Data Collection: Manual tracking is prone to errors, time-consuming, and simply not scalable. For logistics directors, tech companies, or real estate brokers, the sheer volume of data makes manual efforts impossible. Leveraging automation tools like Zapier, Make.com, or custom-built systems is non-negotiable for accurate, real-time reporting. This frees your team from tedious data entry and empowers them to focus on analysis and strategy.

By embedding these metrics into your daily workflows and building a culture that values data-driven decisions, you create a powerful engine for continuous improvement. This proactive approach turns operational efficiency from a technical objective into your most potent competitive advantage, driving sustainable growth and ensuring long-term resilience in a competitive market.

Ready to stop manually tracking data and start automatically improving your operations? The team at Flow Genius specializes in building custom automation and integration solutions that feed directly into your operational efficiency metrics. Let us build the workflows that connect your CRM, project management tools, and communication platforms, giving you the real-time insights you need to thrive. Learn how **Flow Genius** can transform your business today.

Comments