What is Lean Process Improvement? Boost Efficiency Today

- Matthew Amann

- Sep 12, 2025

- 14 min read

Lean process improvement is really just a straightforward idea: systematically get rid of waste so you can give your customers more of what they actually want. It's all about making your operations quicker, smarter, and more effective by cutting out anything that doesn't add real value from the customer's perspective.

Think of it like tuning a high-performance engine. You're not just making it run; you're making it run perfectly.

The Core Idea Behind Lean Thinking

At its heart, lean thinking is a constant, relentless search for a better way. It’s not some one-off project you can check off a list. Instead, it’s a fundamental shift in company culture where everyone, from the top floor to the shop floor, is empowered to spot and eliminate inefficiency.

The ultimate goal is to create a seamless, uninterrupted flow of work that delivers exactly what the customer needs, right when they need it, with zero unnecessary steps or frustrating delays. This entire philosophy grew out of the legendary Toyota Production System and has since been successfully applied in just about every industry imaginable, from software development to healthcare.

The real power of this approach is its sharp focus. By zeroing in on removing "waste," businesses can unlock some truly impressive results. And when we talk about waste, we're not just talking about what goes in the trash bin. In lean, waste is anything that eats up resources but adds zero value.

"Lean is a way of thinking, not a list of things to do." – Shigeo Shingo, a leading expert on the Toyota Production System

Companies that truly embrace lean principles often see huge gains. Data from the Lean Enterprise Institute shows that manufacturers adopting lean can boost productivity by 25% to 50% and cut costs by 20-30%.

These numbers aren't magic; they come from applying a simple but powerful idea. To get started, you first need to understand your current state, which is where mapping out your workflows with our process improvement plan template guide can be a game-changer.

The Eight Wastes of Lean (DOWNTIME)

To really get a handle on what to look for, the lean methodology identifies eight specific types of waste, easily remembered by the acronym DOWNTIME. Spotting these in your own processes is the first major step toward eliminating them.

Waste Type (Acronym) | Description | Example |

|---|---|---|

Defects | Products or services that are incorrect or require rework. This is a direct hit to quality and resources. | A software bug that needs a patch after release, or a manufactured part that doesn't meet specifications. |

Overproduction | Making more of something, or making it sooner, than is needed by the next process or the customer. | A bakery making 200 loaves of sourdough when daily demand is only 100, leading to stale, wasted bread. |

Waiting | Idle time created when people, information, or materials are not ready. | A hospital patient waiting for lab results, or a developer waiting for a code review before they can proceed. |

Non-Utilized Talent | Failing to use the full knowledge, skills, and creativity of your team. | An experienced engineer stuck doing basic data entry instead of solving complex problems. |

Transportation | Unnecessary movement of products and materials from one location to another. | Moving raw materials from a warehouse to the factory floor, then to another station, then back to storage. |

Inventory | Excess products and materials that are not being processed. Excess inventory hides other problems. | A warehouse full of last year's smartphone model that is now difficult to sell at full price. |

Motion | Any movement by people or equipment that is not necessary to perform an operation. | A factory worker having to walk across the room repeatedly to get tools that could be stored at their station. |

Extra-Processing | Doing more work or adding more steps than are necessary from the customer's perspective. | Applying three coats of paint when the customer's specifications only require one for a perfect finish. |

Understanding and internalizing these eight wastes gives you a new lens through which to view your operations. Suddenly, you start seeing opportunities for improvement everywhere.

The Five Principles That Drive Lean Success

Lean isn't just about a set of tools or fancy techniques; it's a fundamental shift in mindset. This mindset is built on five core principles that work in harmony, guiding every decision and action. They're not a checklist to be ticked off, but rather a compass that consistently points your organization toward delivering maximum value to the customer.

Think of these principles as a powerful, self-reinforcing cycle. Each one builds on the last, creating a loop of continuous improvement that can genuinely reshape how you do business.

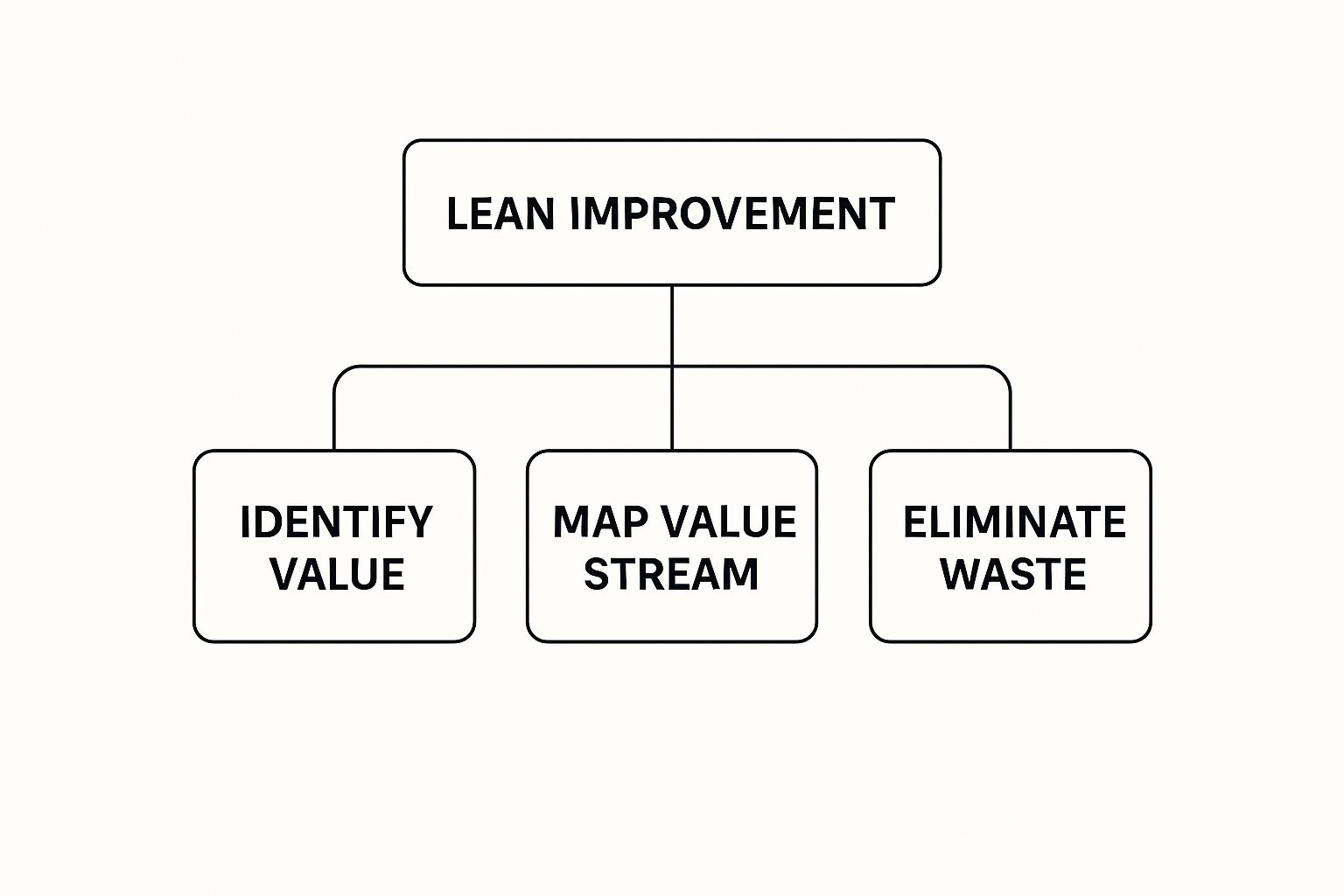

The image below gives a great visual of this hierarchy, showing how everything in Lean starts with one thing: identifying true value.

As you can see, the entire journey begins with understanding the customer's perspective, which then naturally leads to mapping out the process and hunting down waste.

1. Define Value From the Customer's Viewpoint

The first and most critical principle is deceptively simple: value is defined by the customer, and absolutely nothing else. It’s easy to get caught up in what we think is important or what’s easiest for us to produce. But if the customer isn't willing to pay for it, it isn't value. Period.

A software team might spend months building a technically brilliant new feature. If users don't need it or find it confusing, it’s just sophisticated waste. Real value might be a simple bug fix that stops their system from crashing or a redesigned interface that saves them five minutes every day.

This principle forces you to step outside your own four walls and see your work through the eyes of the people who actually use it.

2. Map the Entire Value Stream

Once you know what your customer truly values, the next job is to map the value stream. This is the entire sequence of actions—from initial concept to final delivery—required to bring that value to the customer. We're talking about everything: design, sourcing, production, and shipping.

The goal here is to get a brutally honest, high-level view of every single step. By laying out the entire process, both the good and the bad, you can instantly see where the eight wastes (DOWNTIME) are lurking. This map isn't just a diagram; it's your treasure map for finding improvement opportunities.

3. Create an Uninterrupted Flow

With your value stream mapped out, the third principle is to create flow. This is all about making work move smoothly from one step to the next without any of the delays, bottlenecks, or interruptions you just identified. When you start eliminating waste, flow is the natural result.

Picture a fulfillment center where an order sits in a bin for hours, just waiting for someone at the next station. That’s a classic example of broken flow. In a lean process, that order would move seamlessly from picking to packing to shipping, drastically cutting down the time it takes to get to the customer.

4. Establish a Pull System

The fourth principle, establishing pull, completely flips the script on traditional production. Instead of "pushing" products out into the world based on forecasts and best guesses, a pull system means you only create what the customer has asked for. Work is triggered by real demand, not by a prediction.

"Mistakes are inevitable, but the defects that arise from them are not." – Shigeo Shingo

Toyota famously mastered this approach. By doing so, they minimized overproduction and slashed their inventory—two of the biggest and costliest forms of waste. It ensures you’re only using your time, money, and materials to create something that already has a home.

5. Pursue Absolute Perfection

Finally, the fifth principle is a relentless pursuit of perfection. This isn't about reaching some mythical, flawless state. It's about embedding continuous improvement—known as kaizen—into the very DNA of your company culture.

This last step makes Lean a never-ending journey, not a one-and-done project. By constantly cycling back through the first four principles, your organization will always be finding new ways to define value, spot waste, and improve flow. It creates an environment where everyone, every single day, is empowered to make things just a little bit better.

Mastering the Tools in the Lean Toolbox

Understanding the principles of Lean is the first step, but putting them into practice is where the real work begins. This is where the Lean toolbox comes in. It’s not about fancy software or expensive machinery; it’s a collection of practical, often visual, methods that make waste impossible to ignore and give teams the power to solve problems on the spot.

These tools are what connect the high-level philosophy of Lean to the day-to-day grind. Each one has a specific job, whether it's mapping out a workflow, tidying up a physical space, or stopping errors before they even have a chance to happen.

Visualizing Workflow With Kanban

One of the most widely used Lean tools is the Kanban board. Born at Toyota, Kanban (which is Japanese for "visual signal") is a brilliantly simple way for teams to see their entire workflow in one place. At its core, it's just a board with columns that represent the different stages of a process—think "To Do," "In Progress," and "Done."

Imagine a marketing team swamped with content requests. By putting each blog post or video idea on a card and moving it across a Kanban board, bottlenecks become obvious. If the "In Review" column is overflowing while "Writing" is empty, everyone knows exactly where the logjam is. This simple act of making work visible keeps tasks from falling through the cracks and gets everyone on the same page.

For a deeper dive into how tools like Kanban fit into the bigger picture, this guide to process improvement methodology offers a fantastic overview.

Creating Order With the 5S System

The 5S method is another cornerstone tool, focused on creating a clean, organized, and efficient workspace. It's a systematic, five-step approach to decluttering a physical or digital environment, which directly cuts down on the waste of unnecessary motion and waiting.

The five steps are:

Sort (Seiri): Get rid of everything you don't need in the work area.

Set in Order (Seiton): Give everything that remains a specific, logical home.

Shine (Seiso): Clean the workspace and make tidiness a daily routine.

Standardize (Seiketsu): Create clear rules and procedures to keep the first three S's in place.

Sustain (Shitsuke): Build the habits that make 5S a natural part of your company culture.

Think about a hospital emergency room. Applying 5S means critical supplies like defibrillators and bandages are always in the same clearly labeled spot. No one wastes precious seconds frantically searching during a crisis, which can directly improve patient outcomes.

The goal of Lean is not to be Lean, but to be able to deliver more value to your customer. By applying these tools, you're building a system that achieves just that.

Advanced Tools for Deeper Insights

Beyond the foundational tools, Lean offers more advanced methods for getting to the root of problems. Value Stream Mapping (VSM) is a powerful technique for diagramming every single step in your process, from customer request to final delivery. By mapping it all out, you can pinpoint exactly where the delays and waste are hiding.

Another brilliant concept is Poka-Yoke, which literally means "mistake-proofing." It’s about designing your processes so that it’s physically impossible to make a mistake. The USB cable that only fits one way is a perfect, everyday example of Poka-Yoke in action.

The Lean toolbox is also evolving with technology. For example, modern accounting automation tools are a great example of how software can be used to eliminate manual data entry—a classic form of process waste.

By mastering these tools, you're not just tweaking a process here and there. You're systematically building a stronger, more efficient, and more resilient operation from the ground up.

What You Really Get From Going Lean

Jumping into lean process improvement isn't just about cleaning up a messy workflow. It's about starting a chain reaction that strengthens the entire business, from the ground up.

Think about it: when you make a small operational change, like shortening a lead time or improving product quality, you're not just tweaking a process. You're directly impacting the company's financial health. Smoother, faster operations almost always lead to a healthier bottom line.

Connecting Process to Profit

This is where the magic happens. Those small operational wins become the engine for real financial gains.

Let's say you figure out how to deliver your service 20% faster. That means you get paid sooner, which immediately improves your cash flow. Or maybe you eliminate a common defect in your product. Suddenly, you're not wasting money on rework, returns, or warranty claims. That's pure profit going straight back into the business.

"Lean creates a direct line of sight between small, daily improvements and significant, long-term financial health. It turns operational excellence into a reliable source of business growth."

These efficiencies give you a serious edge. You start delivering better products to your customers, faster than your competition. That’s how you grab market share and earn loyalty that lasts.

It's Not Just About the Numbers

The financial perks are great, but the cultural shift that lean brings is often the real prize. When you give your team the power to spot and solve problems themselves, their engagement goes through the roof.

They're no longer just cogs in a machine. They become invested owners of their work, actively shaping the company's success. That problem-solving mindset gets woven into the fabric of your organization.

This creates a culture where everyone is always looking for a better way—a safer, smarter, more efficient way—to get things done. You’re not just fixing today's problems; you're building a team that's ready for tomorrow's challenges.

The best part is how these benefits feed into each other, creating a powerful loop of positive change:

Improved Quality: You stop patching over mistakes and start fixing the root causes of errors. This means happier customers and fewer costly blunders.

Increased Productivity: By cutting out the fluff, your team can achieve more without burning out. You get more done with the resources you already have.

Enhanced Employee Morale: People who have a say in how their work gets done are happier and more satisfied. This feeling of ownership is a huge morale booster and helps reduce turnover.

Greater Profitability: When you combine higher productivity with less waste, the financial results speak for themselves. Streamlined operations are one of the most reliable ways to find proven strategies to reduce operating costs.

Ultimately, lean is about building a stronger, more competitive, and more resilient business from the inside out.

Navigating the Challenges of Lean Implementation

Adopting a lean approach is a powerful move, but let's be honest—the path isn't always a straight line. While the benefits are huge, the journey often involves navigating some very real, very human challenges. Knowing what these roadblocks are ahead of time is the first step to clearing them.

The shift to a lean mindset requires more than just learning new tools. It demands a fundamental change in your company's culture, and this is often where the real friction happens. Teams can be resistant to changing long-standing habits, and leadership might not fully grasp what it takes to actually support the transformation.

Overcoming Resistance to Change

One of the most common hurdles you'll face is pushback from employees. People naturally get comfortable with their routines, and a call to change can feel like a personal critique of how they've been doing their job. Skepticism can take root fast if the "why" behind the change isn't communicated clearly and often.

The best way to turn skeptics into champions is to get them involved. Don't just hand down a finished plan from on high; invite teams into the process of spotting waste and brainstorming better ways to work. When people have a hand in designing the new system, they feel a sense of ownership and are far more likely to get on board.

Another great strategy is to start with small, visible wins. Instead of trying to overhaul the entire company from day one, find one frustrating bottleneck and fix it. Celebrating that small success builds momentum and shows everyone—in a tangible way—that this lean stuff really does make their jobs better.

Securing True Leadership Buy-In

Let's be clear: you can't have a successful lean implementation without genuine, active support from the top. It’s not enough for executives to simply give the initiative a thumbs-up. They have to be its most visible advocates. That means providing the right resources, knocking down organizational barriers, and walking the walk themselves.

A common pitfall is when leadership treats lean like a one-off project with a start and end date. True success comes from a long-term commitment to continuous improvement. Leaders have to consistently reinforce the message that this is simply how we operate now, not just a temporary flavor of the month.

The human element is the most critical component of any lean transformation. When you focus on empowering people and building a supportive culture, the tools and processes will follow.

Research backs this up time and time again. In fact, studies suggest that 60-70% of lean success hinges on culture and employee engagement, while only 30-40% is about the tools themselves. Common mistakes, like launching too many projects at once or not giving teams the resources they need, almost always stem from a disconnect between the tools and the people meant to use them. You can dive deeper into this by learning about common implementation pitfalls.

Your First Steps on the Lean Journey

It’s easy to get excited about what lean can do for your business. The real challenge? Turning that initial spark of inspiration into real-world action. The trick is to resist the urge to overhaul your entire operation overnight. The lean journey starts with a single, manageable step.

Don’t get bogged down by the big picture. Instead, zero in on one specific area where you can make a tangible difference. This strategy helps you build momentum and show everyone the value of lean thinking, fast. A great place to start is with a recurring, frustrating problem—that one issue the team is always complaining about. A quick win there can turn even the biggest skeptics into believers.

Simple Starting Points

To get the ball rolling, try one of these practical first steps. They don't require a big budget or tons of resources, but they offer a huge return in terms of learning.

Conduct a "Waste Walk": This is as simple as it sounds. Grab a notepad, pick a process, and physically walk it from beginning to end. Watch every single action, delay, and handoff. You will be absolutely stunned by the inefficiencies you uncover just by observing with a fresh perspective.

Map One Workflow: Get your team together in front of a whiteboard. Have everyone map out a single process from start to finish using sticky notes for each step. This simple, collaborative exercise makes bottlenecks and redundant tasks jump out at you in a way that’s impossible to ignore.

The goal isn’t perfection right out of the gate. It’s about sparking a culture of continuous improvement by proving that small, focused changes can deliver surprisingly big results.

By taking these first steps, you'll start building the confidence and practical know-how you need to create a leaner, more effective organization.

Common Questions We Hear About Lean

Even with a good grasp of the basics, a few questions always seem to pop up when people first start digging into lean process improvement. Let's clear the air on some of the most common ones.

Getting these details straight can make a huge difference in understanding how lean actually feels and functions in the real world.

What's the Difference Between Lean and Six Sigma?

It's a classic question because you often hear them mentioned in the same breath. The easiest way to think about it is this: Lean is all about speed, while Six Sigma is all about quality.

Lean’s main obsession is removing waste to make processes flow faster and more efficiently. It constantly asks, "How can we deliver value to the customer sooner?"

Six Sigma, on the other hand, is a deep dive into data and statistics. Its goal is to hunt down defects and variations in a process until the output is incredibly consistent and predictable. It’s always asking, "How can we make this process nearly perfect, every single time?"

That's why you see so many organizations using "Lean Six Sigma." It's a hybrid approach that combines the best of both worlds. You get processes that are not only fast and waste-free (thanks to Lean) but also exceptionally reliable and high-quality (thanks to Six Sigma).

Can Lean Really Work Outside of a Factory?

Absolutely. It’s a common misconception that Lean is only for manufacturing. While its story began on the Toyota factory floor, its principles are about improving any process with a customer and a workflow.

You just have to learn to see "waste" in a different context.

In healthcare, it’s used to slash patient wait times, get lab results back faster, and organize operating rooms to prevent delays and mistakes.

In software development, Agile and Scrum are direct descendants of Lean thinking. They focus on shipping valuable code in small, quick cycles and cutting out pointless meetings or documentation.

In government agencies, Lean helps untangle bureaucratic red tape, simplify paperwork, and deliver public services much more efficiently.

The "product" might be a clean bill of health or a software feature instead of a car, but the core idea of maximizing value by eliminating waste is universal.

What's the Single Most Important Thing for a Successful Lean Rollout?

While tools like Kanban boards and 5S are great, they're not the most important piece of the puzzle. The one thing that will make or break any Lean initiative is unshakeable commitment from leadership and a genuine cultural shift.

Lean isn't a "project" you finish. It’s a whole new way of thinking that has to permeate every corner of the organization.

Leaders can't just sign off on the plan and walk away. They have to live and breathe it—providing the resources, celebrating small wins, and empowering every last employee to speak up about problems and test out solutions. Without that deep support from the top and active participation from everyone else, any improvements you make will fizzle out fast.

At Flow Genius, we specialize in implementing the core principles of lean by automating the wasteful, repetitive tasks that slow your business down. We build intelligent workflows that create flow and give your team back the time to focus on delivering true value. Discover how our smart automation services can make your operations leaner and more efficient.