- Oct 8, 2025

- 15 min read

In today's competitive economy, the key to scaling isn't just working harder; it's working smarter. Business process automation (BPA) has shifted from a niche technology to a fundamental strategy for any company seeking sustainable growth, enhanced efficiency, and operational resilience. By strategically delegating repetitive, rule-based tasks to specialized software, you liberate your team to concentrate on high-value activities that truly drive the business forward: innovation, strategic planning, and building strong customer relationships.

This strategic shift does more than just improve your bottom line; it fundamentally transforms your organizational capacity. In the rapidly evolving business landscape, adopting powerful automation tools has become essential for staying competitive. For instance, marketers now rely on sophisticated Google Ads automation tools to optimize campaigns at a scale impossible to manage manually. But what are the concrete, tangible outcomes of implementing automation across your entire organization?

This definitive guide breaks down the eight most impactful benefits of automating business processes. We will move beyond theory to provide real-world examples and actionable steps, demonstrating how BPA can revolutionize your operations, from finance and marketing to customer service. Prepare to discover how to unlock your company's full potential and drive unprecedented growth.

1. Increased Operational Efficiency and Productivity

One of the most immediate and impactful benefits of automating business processes is the dramatic boost in operational efficiency and team productivity. By automating manual, repetitive tasks, organizations free up valuable human capital, allowing employees to focus on strategic initiatives that drive growth. Routine activities like data entry, invoice processing, and report generation, which once consumed hours, can be completed in seconds with precision.

This shift allows your team to move from low-value, administrative work to high-value activities that require creativity, critical thinking, and complex problem-solving. Instead of manually reconciling spreadsheets, your finance team can analyze spending trends. Instead of copying and pasting customer data, your sales team can spend more time building relationships. The result is a more engaged, strategic, and productive workforce.

Real-World Impact of Automation

Leading companies demonstrate the transformative power of automation. For example, Amazon’s use of robotic systems in its warehouses increased its package processing productivity by 50%. Similarly, PayPal automated its fraud detection, cutting review times from days to mere seconds while handling millions of daily transactions. Coca-Cola also saw a 40% reduction in stock processing time by automating its inventory management system.

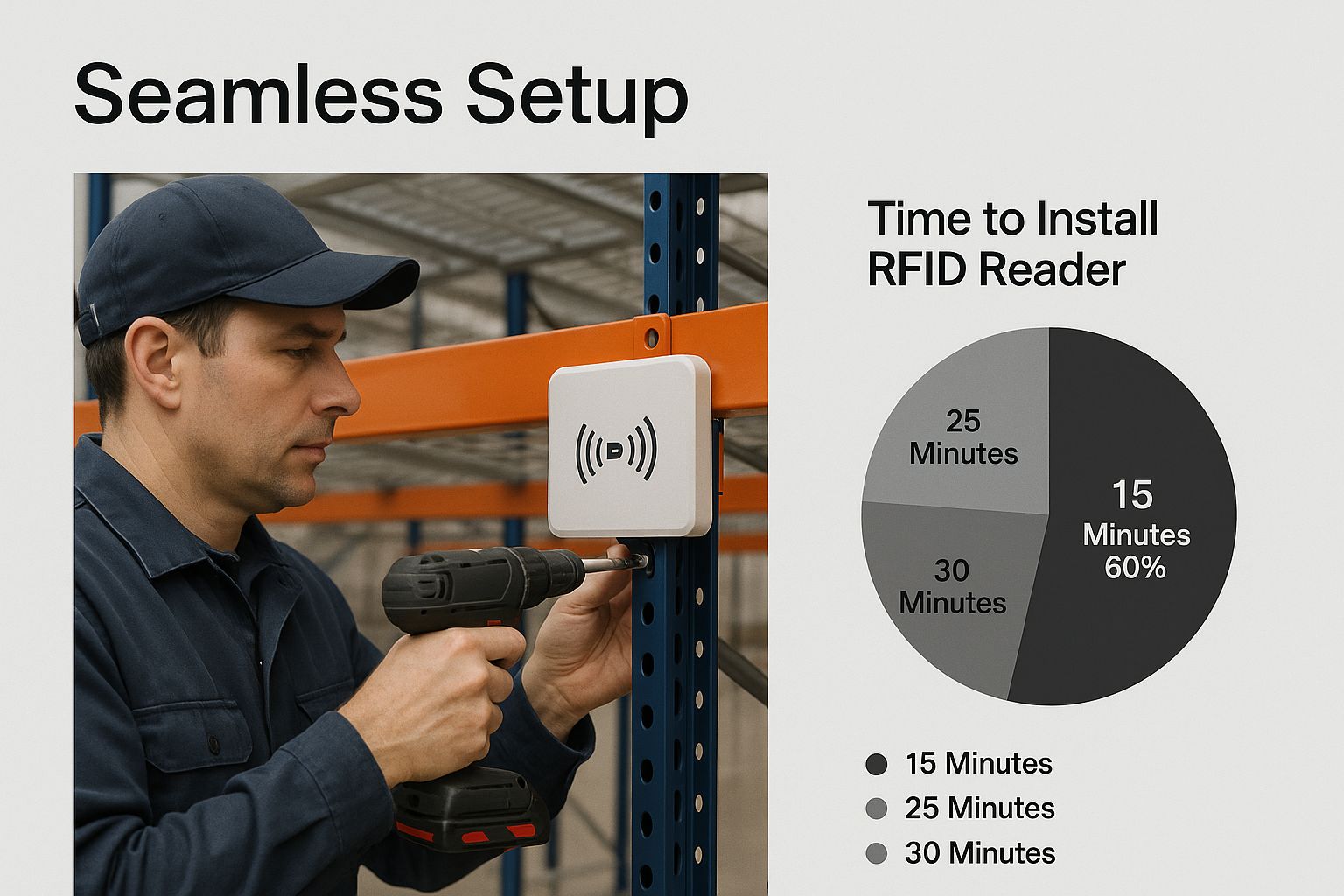

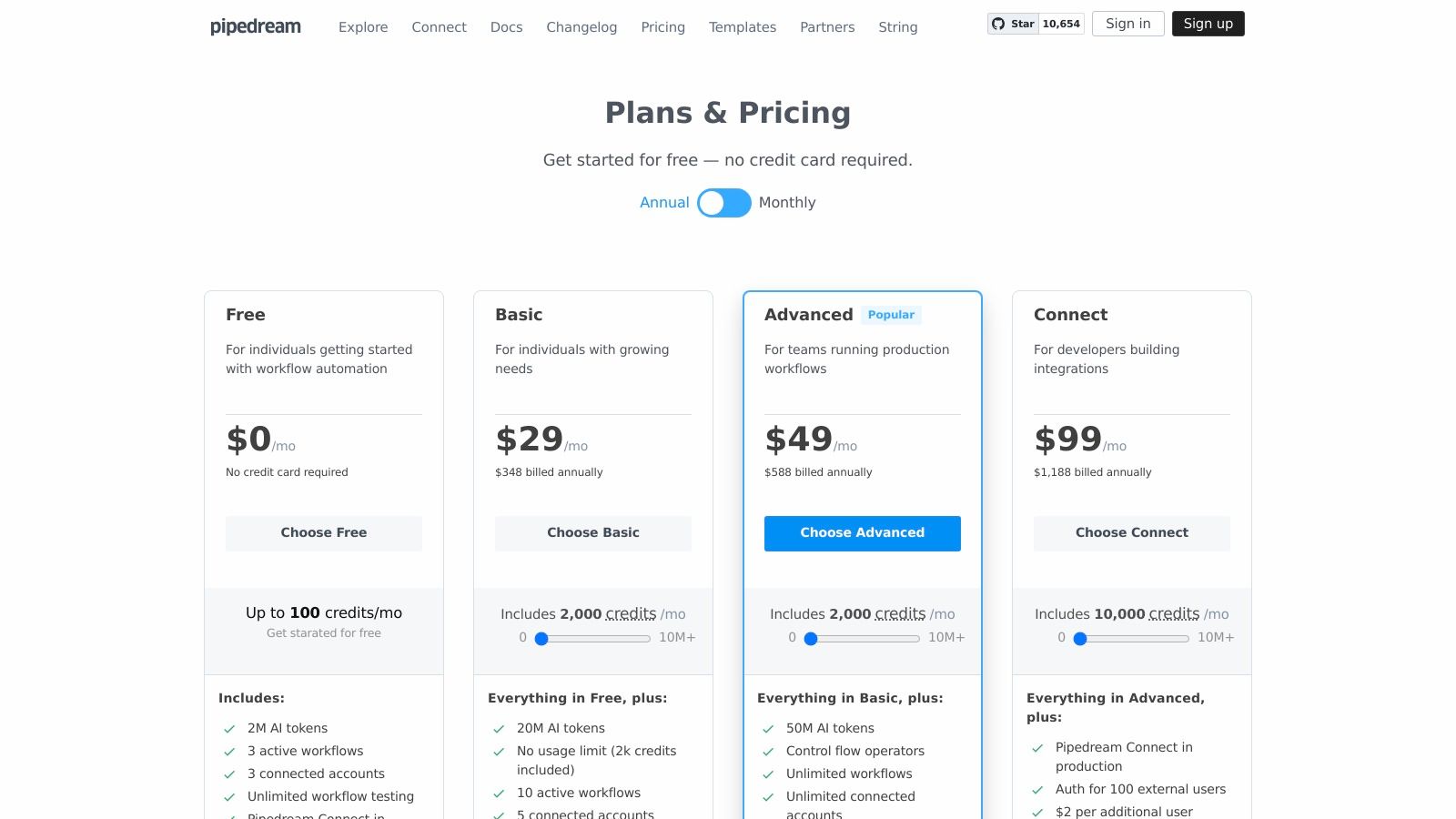

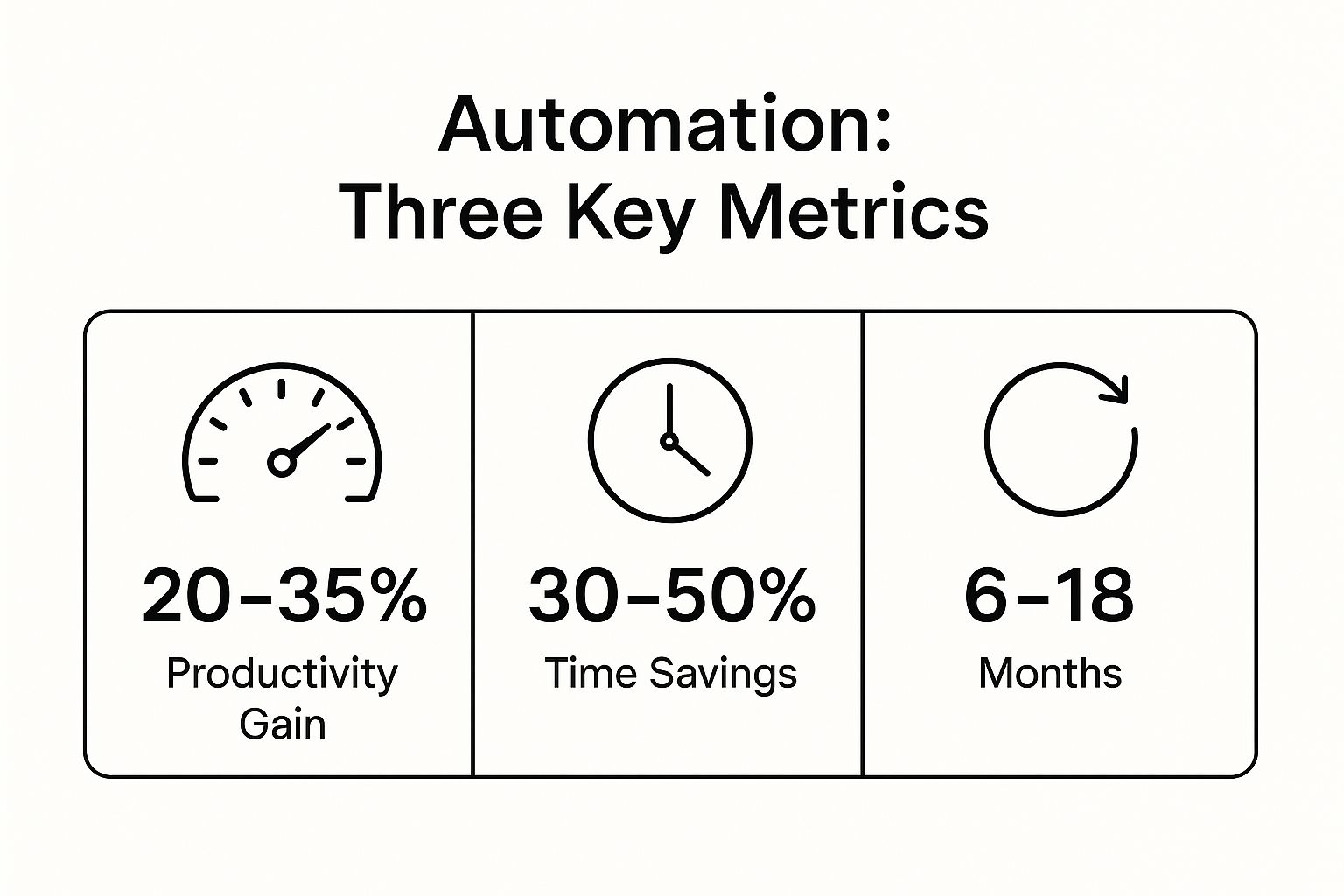

The following infographic highlights the typical gains organizations can expect when they implement business process automation.

These figures show that automation delivers not just incremental improvements but substantial gains in productivity and time savings, often with a rapid return on investment.

How to Get Started

To harness these benefits, start small and build momentum.

Identify Bottlenecks: Use time-tracking tools or conduct process audits to pinpoint the most time-consuming, repetitive tasks within your workflows.

Prioritize Quick Wins: Focus on automating high-volume, low-complexity tasks first. This builds confidence and demonstrates value quickly.

Measure Everything: Establish baseline metrics before you begin. Calculate the average time per task or cost per transaction to accurately measure the improvement post-automation.

By methodically replacing manual effort with streamlined, automated systems, you can significantly enhance your operational capacity. For more strategies on maximizing team output, explore our guide on how to improve team productivity.

2. Enhanced Accuracy and Error Reduction

Another one of the key benefits of automating business processes is a significant improvement in accuracy. Automated systems perform tasks with consistent, machine-level precision, virtually eliminating the human errors that often occur in manual data entry, calculations, and other repetitive activities. This heightened accuracy is crucial in compliance-heavy industries and financial operations where even small mistakes can lead to major financial losses, regulatory penalties, or damaged customer trust.

Automation ensures that every step in a process follows pre-defined rules and specifications without deviation. Whether it's processing invoices, transferring customer data between systems, or tracking inventory, the system executes the task identically every time. This consistency maintains high data integrity and ensures a reliable standard of operational quality across the board, safeguarding your business from costly and time-consuming rework.

Real-World Impact of Automation

Global leaders have leveraged automation to achieve near-perfect accuracy. For instance, UnitedHealthcare automated its claims processing, dramatically reducing error rates from 30% down to less than 1% and saving an estimated $30 million annually. Similarly, JPMorgan Chase implemented its COIN (Contract Intelligence) platform to review commercial loan agreements, which eliminated 360,000 hours of manual legal work and cut review errors by 95%. Retail giant Walmart also automated its inventory tracking, leading to a 63% reduction in stock discrepancies across its vast network of stores.

These examples underscore how automation directly translates to fewer mistakes and substantial operational savings.

How to Get Started

To boost accuracy in your own operations, you can take a systematic approach to automation.

Implement Validation Rules: Build validation checks at every data entry point within your automated workflows. This ensures data is correct and properly formatted before it proceeds.

Run Parallel Testing: Before fully switching over, operate the new automated process alongside your existing manual one. Compare the outputs to verify the system's accuracy and iron out any issues.

Create Exception Reports: Configure your system to automatically flag any unusual cases or data points that fall outside normal parameters. These exceptions can then be routed for human review.

Schedule Regular Audits: Periodically audit your automated processes to ensure they continue to perform as expected and haven't drifted from their intended business rules.

By prioritizing accuracy, you can build more resilient, reliable, and trustworthy business operations. For more on creating efficient workflows, see our guide on how to automate CRM workflows.

3. Significant Cost Reduction and Resource Optimization

Beyond improving efficiency, one of the most compelling benefits of automating business processes is the direct and substantial reduction in operational costs. Automation cuts expenses by minimizing the need for manual labor, reducing costly human errors, and optimizing the use of every resource, from materials to software licenses. While implementing automation technology requires an initial investment, the return is often swift and significant.

By automating tasks like invoice processing, procurement, and payroll, organizations eliminate thousands of hours of manual work. This allows businesses to achieve more with their existing team, delaying the need for additional hires and reallocating labor budgets toward strategic growth initiatives. This optimization leads to a leaner, more cost-effective operational model.

Real-World Impact of Automation

Global industry leaders provide powerful examples of cost savings through automation. Siemens, for instance, automated its invoice processing, slashing the cost per invoice from $18 to just $3 and saving the company $100 million annually. Similarly, IBM leveraged business process automation across its operations to cut costs by $300 million per year. Procter & Gamble also automated key supply chain functions, resulting in a 15% reduction in operational costs, which translated to an impressive $900 million in annual savings.

These examples underscore how automation delivers tangible financial returns by fundamentally changing how work gets done, transforming cost centers into models of efficiency.

How to Get Started

To unlock these cost-saving benefits, take a strategic approach to implementation.

Conduct a Cost-Benefit Analysis: Before starting, perform a detailed analysis that includes all potential expenses like software licenses, training, and ongoing maintenance to ensure a clear understanding of the total investment.

Prioritize High-Cost Processes: Identify business functions with high labor costs, error rates, or material waste. These are prime candidates for automation as they offer the quickest and most significant ROI.

Track Direct and Indirect Savings: Measure both direct savings, such as reduced labor hours, and indirect savings, like lower error-related costs and faster transaction cycles, to capture the full financial impact.

By focusing on processes where automation can deliver measurable financial returns, you can build a strong business case for wider adoption. For more in-depth techniques, explore our guide on top cost reduction strategies for high-value sectors.

4. Improved Customer Experience and Satisfaction

Automating business processes is a powerful strategy for enhancing the customer experience, leading to greater satisfaction and loyalty. By automating key customer-facing interactions, businesses can deliver faster, more consistent, and highly personalized service around the clock. Processes like order confirmations, support ticket routing, and status updates are executed instantly, ensuring customers feel informed and valued at every stage.

This consistency and speed directly impact customer perception. When a customer receives an immediate, helpful response to a query at any time of day, it builds trust and confidence in your brand. Automation allows you to proactively manage the customer journey, reducing friction and demonstrating that you respect their time. This elevates the entire experience from a simple transaction to a seamless, supportive relationship, which is a key differentiator in today's competitive market.

Real-World Impact of Automation

Leading brands leverage automation to create exceptional customer interactions. For example, Domino's Pizza automated its order tracking, allowing customers to follow their pizza's journey in real-time. This simple feature increased customer satisfaction by 15%. Sephora's AI-powered chatbot provides personalized beauty recommendations, handling millions of conversations with a 91% satisfaction rate.

Similarly, Bank of America's virtual assistant, Erica, has managed over 1 billion client requests, resolving common issues 50% faster than traditional methods. These examples show how automation directly translates into a more responsive, transparent, and satisfying customer experience, which is one of the most significant benefits of automating business processes.

How to Get Started

To elevate your customer experience with automation, focus on high-impact touchpoints.

Map the Customer Journey: Identify every interaction point a customer has with your business, from initial contact to post-purchase follow-up. Pinpoint areas where speed, consistency, or personalization are most critical.

Prioritize Proactive Communication: Use automation to be proactive. Instead of waiting for customers to ask for an update, set up automated notifications for order shipments, appointment reminders, or potential service delays.

Maintain a Human Touch: While automating routine queries, always provide a clear and easy option for customers to connect with a human representative for more complex or sensitive issues.

Personalize at Scale: Leverage customer data from your CRM to personalize automated communications. Use their name, purchase history, and preferences to make every interaction feel relevant and tailored.

5. Better Compliance and Risk Management

Automating business processes provides a robust framework for superior compliance and risk management. By systemizing workflows, organizations ensure that all regulatory requirements, industry standards, and internal policies are consistently enforced without manual oversight or human error. Automation creates an indelible audit trail, maintaining detailed, timestamped records of every transaction, decision, and approval, which is one of the key benefits of automating business processes.

This systematic approach drastically reduces the risk of regulatory violations, costly penalties, and potential legal issues. Instead of scrambling for documentation during an audit, teams can generate comprehensive compliance reports automatically. This shifts the compliance function from a reactive, manual effort to a proactive, integrated part of daily operations, making audits smoother and less disruptive.

Real-World Impact of Automation

Global leaders across regulated industries leverage automation to fortify their compliance frameworks. For example, HSBC automated its anti-money laundering (AML) transaction monitoring, enabling it to process 95% of alerts automatically and slash compliance costs by 70%. Similarly, Johnson & Johnson automated its pharmaceutical quality control processes to ensure strict FDA compliance, cutting compliance-related delays by 40%.

AXA Insurance also saw remarkable results by automating its policy underwriting compliance checks. This initiative reduced non-compliance incidents by an impressive 85% and compressed audit preparation time from several weeks down to just a few days. These cases highlight how automation transforms compliance from a business burden into a competitive advantage.

How to Get Started

To build a more resilient compliance strategy, integrate automation thoughtfully.

Involve Compliance Experts Early: Collaborate with compliance officers during the planning phase to map all regulatory requirements to specific automated workflows.

Implement Monitoring Dashboards: Set up regular, automated compliance reports and real-time dashboards to monitor adherence and flag potential issues instantly.

Enforce Separation of Duties: Use automation to build and enforce strict approval hierarchies and separation of duties, preventing unauthorized actions and potential conflicts of interest.

By embedding compliance rules directly into your automated systems, you create a reliable, transparent, and auditable operational environment.

6. Enhanced Data Management and Business Intelligence

One of the most transformative benefits of automating business processes is the ability to revolutionize data management and unlock powerful business intelligence. Automation systematically captures and structures information from every transaction, interaction, and workflow in real time. This process creates a clean, centralized data repository, eliminating the manual effort and inconsistencies associated with traditional data collection.

By standardizing how data is gathered and integrated across departments, automation breaks down information silos. Instead of fragmented, outdated spreadsheets, your organization gains a unified view of its operations. This high-quality, real-time data becomes the foundation for sophisticated analytics, predictive modeling, and truly data-driven decision making, enabling you to move from reactive adjustments to proactive strategies.

Real-World Impact of Automation

Leading companies leverage automation to turn data into a competitive advantage. For instance, Netflix automated the collection and analysis of viewing patterns, allowing its recommendation engine to drive over 80% of content watched. Similarly, Zara automates sales and inventory data collection across its stores, enabling it to identify trends and move from design to delivery in just two weeks. American Express also automated transaction monitoring, which reduced false positives in fraud detection by 60%.

These examples show how automated data pipelines not only improve efficiency but also generate actionable insights that directly impact revenue, customer satisfaction, and operational resilience.

How to Get Started

To build a data-centric culture with automation, focus on creating a solid foundation.

Design for Data: When designing automated workflows, intentionally identify and tag key data points you want to capture from the very beginning.

Establish Governance: Implement clear data governance policies before launching automation to ensure data quality, consistency, and security across all systems.

Automate Reporting: Create automated dashboards that visualize key metrics and deliver them to relevant stakeholders, eliminating manual report generation.

By strategically automating data management, your organization can harness the insights needed to innovate and outperform the competition. For inspiration, see these powerful business intelligence dashboard examples that turn raw data into strategic assets.

7. Increased Scalability and Business Agility

Another of the core benefits of automating business processes is the ability to scale operations rapidly without proportionally increasing headcount or infrastructure costs. This enhanced scalability and agility are critical for navigating market fluctuations, seasonal demand, and long-term growth. Automation allows a business to handle ten times or even a hundred times the transaction volume with minimal additional investment.

This capability transforms how a company competes. Instead of being constrained by manual capacity, your organization can seize new market opportunities with confidence. Automated systems can process an influx of orders, onboard new clients, or manage increased support tickets without buckling under pressure. This agility means you can adapt your processes quickly as business requirements evolve, staying ahead of the competition in a dynamic environment.

Real-World Impact of Automation

Global leaders across industries leverage automation to achieve massive scale. For example, Shopify’s automated e-commerce infrastructure is built to handle over 10,000 transactions per minute during peak sales events like Black Friday, supporting millions of merchants seamlessly. Similarly, Airbnb automated its host onboarding and guest booking systems, which was essential for its expansion into over 220 countries with minimal local operational staff.

These examples underscore how automation decouples business growth from resource consumption. By building a scalable foundation, companies can focus on innovation and market expansion rather than on hiring to keep up with operational demand.

How to Get Started

To build for scale, you must design your automated systems with future growth in mind from day one.

Design for Modularity: Implement modular automation components that can be adjusted or expanded independently. This prevents having to overhaul the entire system to make a small change.

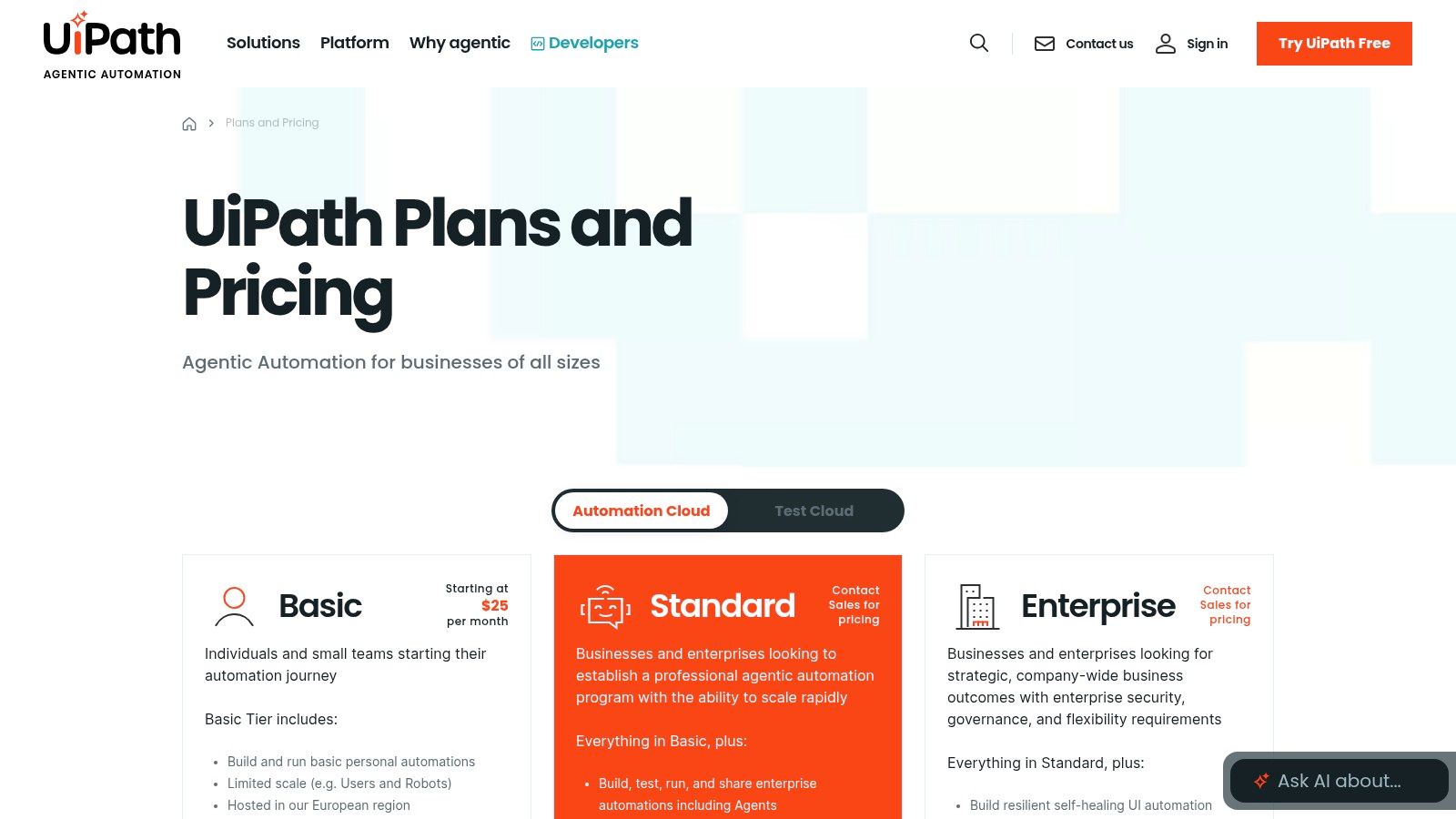

Leverage Cloud Platforms: Use cloud-based automation tools like Zapier, Make, or native CRM workflow builders. These platforms are designed to scale their resources automatically based on your demand.

Avoid Hard-Coded Limits: When creating workflows, avoid setting fixed limits or rules that might become bottlenecks later. Instead, build in flexibility points where business logic can be modified easily without developer intervention.

8. Improved Employee Satisfaction and Retention

One of the most profound benefits of automating business processes is its direct, positive impact on employee morale, job satisfaction, and long-term retention. Automating tedious, repetitive tasks frees your team from monotonous work, allowing them to engage in roles that require human ingenuity, strategic thinking, and creative problem-solving. This shift empowers employees, reduces burnout, and fosters a more fulfilling work environment.

When employees are no longer bogged down by manual data entry, report compilation, or administrative busywork, they can focus on their core competencies and contribute to high-value initiatives. This change not only boosts their sense of purpose and accomplishment but also reduces the frustration associated with manual errors and process bottlenecks. A happier, more engaged workforce is a more stable and innovative one.

Real-World Impact of Automation

Leading companies have demonstrated that investing in automation is an investment in their people. For example, Unilever automated its HR onboarding, slashing the administrative burden by 75% and boosting HR team satisfaction scores by 30%. Similarly, Deloitte automated routine audit documentation, which allowed its auditors to concentrate on complex analysis, resulting in a 25% increase in employee engagement.

These examples show a clear link between reducing manual workloads and creating a more rewarding employee experience. By removing the drudgery from daily routines, companies can unlock higher levels of engagement and loyalty.

How to Get Started

To leverage automation for better employee retention, focus on a human-centric approach.

Involve Your Team: Actively involve employees in identifying the most frustrating and time-consuming tasks. This ensures you’re solving real pain points and gains their buy-in from the start.

Communicate Transparently: Frame automation as a tool to eliminate tedious work, not jobs. Emphasize that the goal is to augment their skills and free them for more meaningful contributions.

Provide Reskilling Opportunities: Offer training and development to help employees transition to higher-value roles. This can include data analysis, automation management, or strategic planning.

Celebrate Wins: Highlight how new automations are improving daily work life. Showcasing quick wins builds momentum and reinforces the positive aspects of the transition.

Benefits Comparison of 8 Key Automation Advantages

Aspect | Increased Operational Efficiency and Productivity | Enhanced Accuracy and Error Reduction | Significant Cost Reduction and Resource Optimization | Improved Customer Experience and Satisfaction | Better Compliance and Risk Management | Enhanced Data Management and Business Intelligence | Increased Scalability and Business Agility | Improved Employee Satisfaction and Retention |

|---|---|---|---|---|---|---|---|---|

Implementation Complexity 🔄 | Moderate; requires process mapping and change management | High; needs thorough testing and exception handling | High; involves significant upfront investment and ongoing costs | Moderate; requires integration of customer data systems | High; careful compliance encoding and frequent updates | High; investment in BI tools and data governance required | High; must design for future growth and modularity | Moderate; involves change management and employee training |

Resource Requirements ⚡ | Medium; automation tools plus staff adaptation | Medium to high; validation and audit systems | High; software, hardware, IT expertise, and training | Medium; customer data platforms and chatbot systems | Medium; compliance officers involvement and system maintenance | High; analytics platforms and trained analysts | Medium to high; cloud platforms recommended for scalability | Medium; reskilling and communication efforts |

Expected Outcomes 📊 ⭐ | 20-35% productivity gain, 30-50% time savings, ROI in 6-18 months | Up to 90% error reduction, improved data quality | 25-80% cost savings in key areas, ROI in 6-24 months | 15-30% customer satisfaction increase, 60-80% faster responses | Reduced compliance violations, faster audit times, improved governance | Immediate data access, trend insights, better forecasting | Handle 10x+ volume, faster response to market, global expansion | 20-35% increase in satisfaction, 15-30% lower turnover |

Ideal Use Cases 💡 | Automating repetitive admin tasks and workflows | Compliance-heavy operations, data entry, financial reconciliation | Cost-sensitive and resource-optimized environments | Customer support automation, personalized communications | Regulated industries like finance, healthcare, manufacturing | Real-time data capture, integrated reporting, predictive analytics | Growing businesses, seasonal spikes, rapid market adaptation | Organizations seeking innovation, employee engagement, retention |

Key Advantages ⭐ ⚡ | Faster processing, 24/7 operation, scalability without proportional resources | Consistent precision, audit trails, reduced error-related costs | Labor cost savings, error cost reduction, predictable expenses | 24/7 availability, personalized CX at scale, higher retention | Automatic compliance enforcement, audit readiness, reduced legal risks | Data-driven decisions, elimination of silos, faster reporting | Scalability without linear cost, quick deployment, flexible workflows | Higher morale, reduced burnout, strategic focus, skill development |

Your Next Step: From Insight to Implementation

Throughout this exploration, we've unpacked the substantial, multi-faceted benefits of automating business processes. We’ve moved beyond abstract concepts to see how tangible gains in efficiency, significant cost reductions, and near-perfect accuracy are not just possible, but repeatable. From streamlining your CRM workflows to automating outbound communication, the evidence is clear: automation is no longer a luxury for large enterprises but a foundational strategy for any company serious about growth, resilience, and competitive advantage.

The journey from manual, error-prone tasks to a sleek, automated ecosystem directly impacts your bottom line and your team's morale. By eliminating repetitive work, you empower your employees to focus on high-value, strategic initiatives that drive innovation. This shift cultivates a more engaged and satisfied workforce, transforming your operational backbone into a powerful engine for progress.

Turning Knowledge into Actionable Strategy

Understanding these benefits is the crucial first step, but the true transformation lies in implementation. The path forward involves a strategic assessment of your current operations to identify the bottlenecks and manual processes that are prime candidates for automation.

Here is a simple framework to get started:

Identify High-Impact, Low-Effort Tasks: Begin by mapping out your daily, weekly, and monthly processes. Look for repetitive, rule-based tasks like data entry, report generation, or client onboarding notifications. These are often the easiest to automate and offer immediate returns.

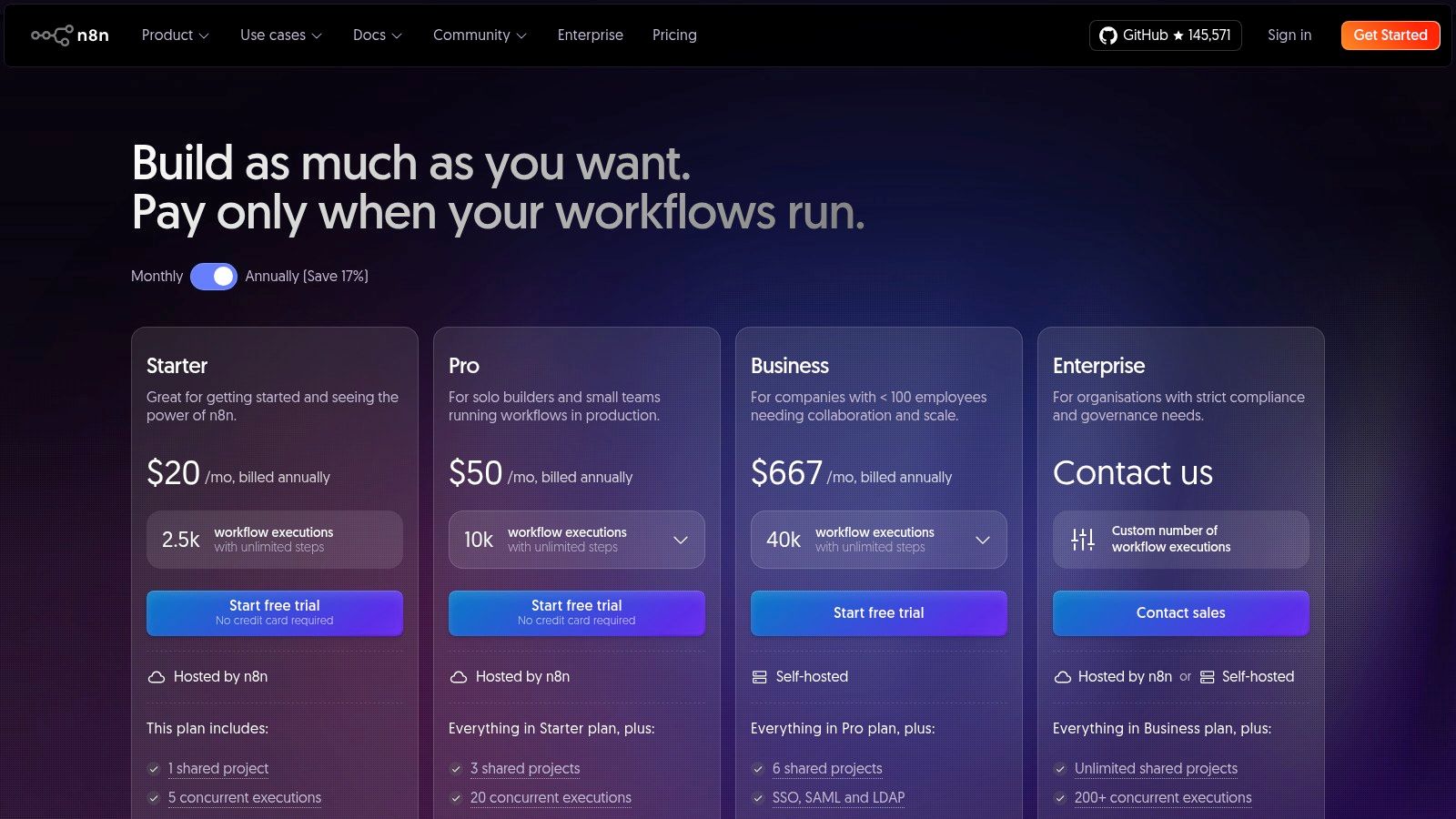

Evaluate Your Existing Tech Stack: Assess the tools you already use, such as your CRM, project management software, or accounting platform. Many of these systems have built-in automation features or can be integrated using platforms like Zapier, Make, or n8n.

Start Small and Scale: You don't need to automate your entire business overnight. Select one or two key workflows to serve as a pilot project. Success in a focused area will build momentum and provide a clear business case for broader adoption.

The Path to Sustainable Growth

Ultimately, embracing the benefits of automating business processes is about future-proofing your organization. It equips you with the agility to scale operations without proportionally increasing your headcount, the data insights to make smarter decisions, and the operational excellence to deliver a superior customer experience. The compounding effect of these advantages creates a formidable competitive moat.

To move from theoretical insight to practical application, consider these real-world business process automation examples to see how businesses in logistics, real estate, and technology are already leveraging these strategies. The mastery of automation is not merely about doing things faster; it's about building a smarter, more resilient, and more resourceful organization poised for whatever comes next.

Ready to transform these insights into a tangible reality for your business? At Flow Genius, we specialize in designing and implementing custom automation strategies that eliminate operational friction and unlock your team's full potential. Visit us at Flow Genius to schedule a consultation and build your blueprint for a more efficient future.