- Aug 25, 2025

- 19 min read

Improving business efficiency isn't about one-off fixes or simply cutting costs. It's about building a living, breathing system—a cycle of auditing your processes, smartly applying technology, and actually measuring what works. Forget the old, siloed way of thinking. Today, it's all about integrating your people, processes, and tech to work in harmony.

Your Blueprint for Modern Business Efficiency

Real gains in efficiency come when you look at the big picture, connecting every part of your organization. This isn't just about saving a few bucks; it's a core driver of resilience, growth, and genuine innovation. The aim is to create a company that not only runs like a well-oiled machine but can also pivot quickly when the market shifts.

To get there, you have to move beyond isolated tweaks and start thinking strategically. For instance, the lessons learned from proven strategies to improve fleet efficiency can be surprisingly applicable to almost any operational area. Adopting this mindset is the first step toward systematically finding and eliminating the friction that's holding your business back.

The Foundation of an Efficient Operation

The journey to better efficiency starts with a simple truth: it’s a continuous loop, not a one-time project. It’s about constantly asking the right questions. Where is time being wasted? Where are communication lines breaking? Where could a simple tool lighten the load for my team?

This entire approach rests on three core pillars:

Process Clarity: You can't improve what you don't fully understand. The simple act of mapping out your workflows is often an eye-opener, revealing hidden redundancies and frustrating bottlenecks.

Technological Integration: The right tools can automate soul-crushing repetitive tasks. This frees up your team to focus on the high-impact, strategic work they were actually hired to do.

People Empowerment: A truly efficient culture is built from the ground up. It’s one where your employees feel comfortable pointing out what's broken and suggesting better ways to get things done.

This isn’t just a nice idea; it’s a massive global priority. In fact, by 2025, spending on digital transformation is projected to rocket past $2.5 trillion. That's a huge investment, all aimed at automating grunt work and building integrated systems that just work better.

"Efficiency is doing things right; effectiveness is doing the right things." - Peter Drucker

This quote from Peter Drucker hits the nail on the head. The goal isn't just to do tasks faster. It's to make sure your team is spending their valuable time on the right tasks—the ones that actually move the needle on growth and keep customers happy.

The Core Pillars of Modern Business Efficiency

To build a sustainable model, it helps to break down efficiency into its fundamental components. This table outlines the essential areas where businesses can achieve lasting gains.

Pillar | Core Objective | Key Actions |

|---|---|---|

Operational Workflow | To eliminate redundancies and bottlenecks in daily tasks. | Map current processes, identify manual steps, and standardize procedures. |

Technology Stack | To connect disparate systems and automate repetitive work. | Audit existing tools, identify integration gaps, and implement automation platforms. |

People & Culture | To foster a mindset of continuous improvement and empowerment. | Provide training on new tools, create feedback channels, and reward innovation. |

Data & Analytics | To make informed decisions based on performance metrics. | Define key performance indicators (KPIs), implement tracking systems, and review data regularly. |

By focusing on these four pillars, you create a balanced approach that addresses not just the "how" but also the "why" and the "who" behind your operations.

Creating a Sustainable Cycle of Improvement

Ultimately, building a truly efficient organization is about embedding this thinking into your company's DNA. It’s about creating a culture where optimization is everyone’s job, not just a line item on a manager's to-do list. When your team feels empowered to question clunky, outdated processes and experiment with better methods, you unlock a powerful, self-sustaining engine for improvement.

The next sections will give you the practical, actionable steps for auditing your workflows, picking the right tools for the job, and measuring the real-world impact of your changes. By following this blueprint, you'll lay the groundwork for an operation that is not just efficient, but also agile and ready for whatever comes next.

Find the Bottlenecks by Auditing Your Workflows

Before you can make anything more efficient, you have to get brutally honest about how things really get done right now. Guesswork won't cut it. A workflow audit is your chance to pull back the curtain and map out your processes, step by step, to see exactly where things get stuck, slow down, or just go completely off the rails.

This isn’t about pointing fingers. It’s about getting a clear picture so you can make smart, targeted improvements. The goal is to create a simple inventory of pain points and time-wasting tasks that are quietly draining your resources and frustrating your team.

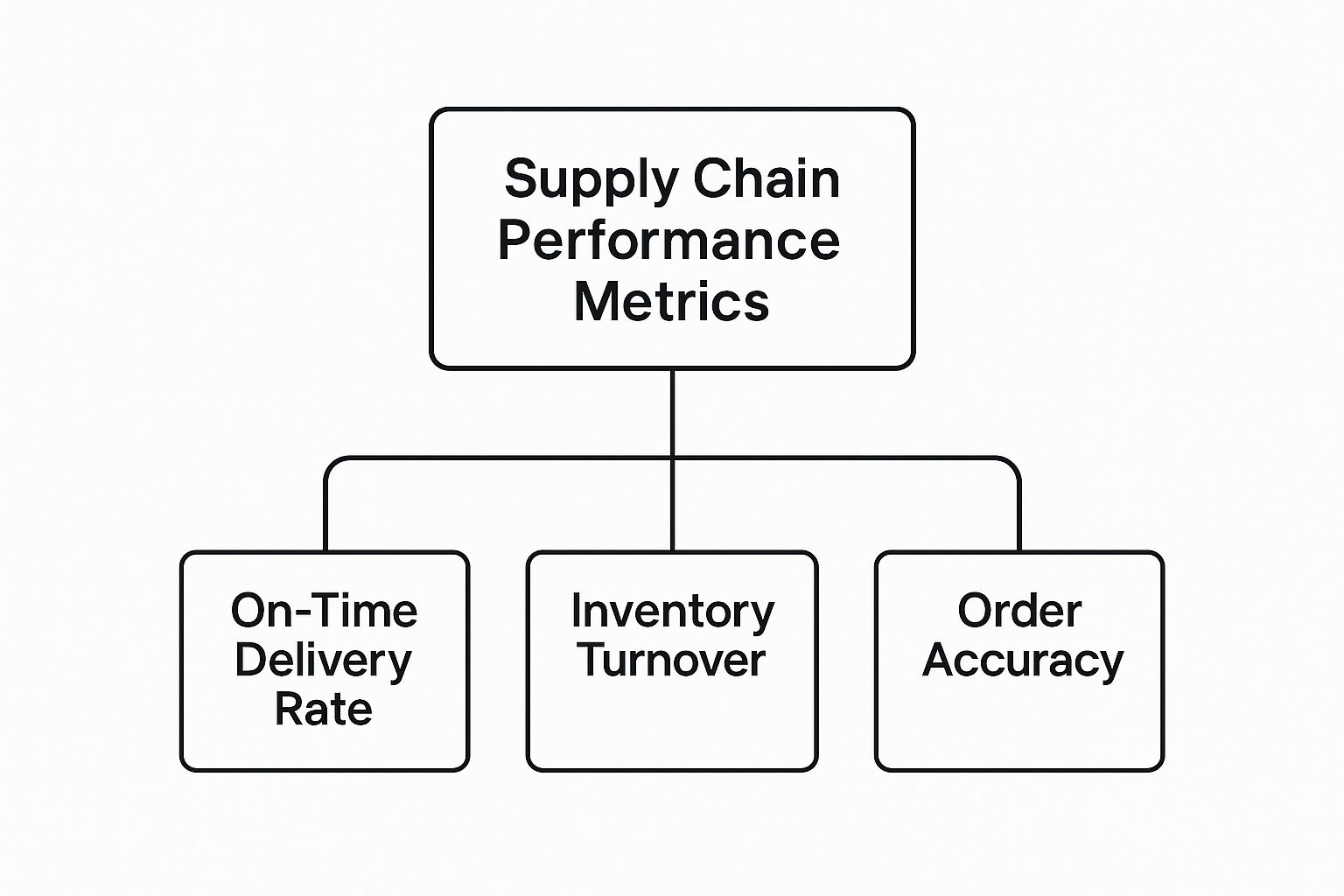

This image really drives home a key point: efficiency isn't just about speed. It’s about creating a connected system where information and tasks flow smoothly from one stage to the next.

Start with One High-Impact Process

Trying to audit everything at once is a surefire way to get overwhelmed and give up. Instead, pick one critical process to start. Good candidates are usually high-value, happen frequently, or are a known source of headaches for your team.

Processes that touch multiple people or departments are often goldmines for improvement, since handoffs are where things most often break down.

Let's take a classic example I see all the time: a marketing team's content approval cycle. It’s a process that is notorious for becoming a bottleneck that stalls campaigns.

The Goal: Publish a blog post.

The Players: A writer, an editor, a designer, a legal reviewer, and the marketing manager.

The Perceived Problem: "It just takes forever to get anything published."

This is a perfect starting point. It’s specific, involves a handful of people, and directly impacts the team's goals. Fix this one workflow, and you'll see a real difference in output.

Map the Messy Reality

Now for the fun part. You need to map the process exactly as it is today—not how it’s supposed to be in the handbook. The best way I’ve found to do this is to get the key people in a room (or on a Zoom call) with a virtual whiteboard.

Start at the beginning and trace the journey of that blog post from the first draft to the moment it goes live. Ask clarifying questions to uncover every single little action.

Kick-off: The writer finishes the draft. What happens immediately after? Do they save it to Google Drive and then send an email? Do they drop a link in a Slack channel? Be specific.

Reviews & Feedback: The editor gets it. How do they leave comments? Directly in the doc with track changes? In a project management tool like Asana? In a separate email with a list of notes?

Handoffs: Once edited, how does the designer get looped in for graphics? How is legal notified for their review? Do these things happen at the same time, or one after another? Every handoff is a potential delay.

Final Go-Ahead: Who gives the final sign-off? How is that approval communicated to the person hitting "publish"?

By the end of this, you’ll have a visual map that probably looks a lot more tangled and chaotic than anyone realized. Seeing it laid out like that is incredibly powerful.

The biggest efficiency killers are almost never the big, obvious steps. They're hidden in the small, unwritten moments between the steps—the waiting, the follow-ups, the confusion, and the miscommunication.

This map is your foundation for understanding what’s really going on. If you want to explore this concept further, our guide on how to improve operational efficiency takes a broader look at these principles.

Pinpoint the Friction

With your messy workflow map staring back at you, the problems will practically jump off the page. Now you can start looking for the common culprits that kill productivity.

Common Bottlenecks to Watch For:

Manual Data Entry: Did someone have to copy and paste the blog post from a Word doc into WordPress? That's a classic automation opportunity.

Approval Delays: Where did the process grind to a halt? You’ll often find it sitting in one person's inbox. The map might reveal a single manager is the chokepoint for 80% of all content approvals.

Lack of Clarity: Do people constantly ask, "Whose court is this in?" or "What's next?" This is a dead giveaway that the process itself is broken.

Redundant Work: Is the same piece of information being typed into multiple systems? For instance, is the blog title updated separately in the document, the project card, and the content calendar?

Circle these friction points right on your map. In doing so, you'll turn a confusing diagram into a prioritized, actionable list of problems to solve. This is no longer just a theory—it's a concrete blueprint showing you exactly where to focus your efforts for the biggest impact.

Choosing the Right Automation Tools for Real Problems

Okay, you've mapped out your workflows and pinpointed the real bottlenecks. That hard work pays off now. Instead of just guessing, you can start looking for tools that solve specific, documented problems. This is the secret—let the problem dictate the tool, not the other way around.

The market for automation tools is massive, which is both good and bad. There’s a solution for almost anything, but the sheer volume of options can feel overwhelming. Your workflow audit is the perfect filter, helping you cut through the noise and find what will actually move the needle for your business.

No-Code Platforms vs. Custom Scripts: What’s the Difference?

Your first big decision is usually whether to go with a ready-made "no-code" platform or build something from scratch with a custom script. Understanding the pros and cons here is essential for making a choice that serves you both now and in the future.

No-code platforms like Zapier or Make are the Swiss Army knives of the automation world. They’re designed to act as translators between the apps you already use, letting them share data and trigger actions without you lifting a finger.

On the other hand, custom scripts are specialized tools crafted for one unique, and often complex, job. Think of these as small programs, usually written in a language like Python, built to handle a very specific sequence of tasks that no-code platforms just can't manage.

Here’s a simple way to think about it:

No-Code Platforms (Zapier, Make): Perfect for connecting popular cloud apps. If you want to automatically create a Trello card from a new email in Gmail or add a lead from your website form to a Mailchimp list, a no-code tool is your best bet. It’s fast, visual, and requires no programming knowledge.

Custom Scripts: The right choice for unique internal processes, heavy data manipulation, or integrating with systems that don't have an "app" you can connect to. For instance, scraping specific data from a competitor’s website and organizing it into an internal spreadsheet is a classic job for a custom script.

My advice? Always start with the simplest solution that gets the job done. Over-engineering a fix with a complex script when a simple Zap would have worked is just trading one form of inefficiency for another.

The goal is not to find a tool you can use, but to identify a problem that a tool must solve. Start with the pain point, and the right technology will become obvious.

This mindset keeps you from getting distracted by flashy features you’ll never use and puts the focus back where it belongs: making your business run smoother.

A Practical Framework for Picking a Tool

When you're looking at different automation tools, it’s easy to fall down a rabbit hole comparing feature lists. Instead, I use a simple framework that focuses on the practical needs of the business and the specific problem I'm trying to solve.

Problem-Solution Fit: Does this tool actually solve the problem you identified? Don't settle for something that almost fixes it. If your bottleneck is manually copying data from a Typeform submission into your CRM, the tool must have solid, reliable integrations with both of those specific platforms. No exceptions.

Scalability: Think about the future. A tool that works for 10 tasks a day might crumble or become wildly expensive at 100 or 1,000. Look at the pricing tiers. Does the cost balloon as your usage grows? Make sure the solution can grow with you.

Ease of Use & Maintenance: How much technical skill is needed to get this running and keep it running? No-code tools are usually DIY, but custom scripts need a developer to build and to fix them when they inevitably break. That ongoing maintenance is a real cost you need to factor in.

Using this simple three-point check helps you make a strategic choice that provides immediate relief and won't create new headaches down the road.

Start Small, Win Big, and Build Momentum

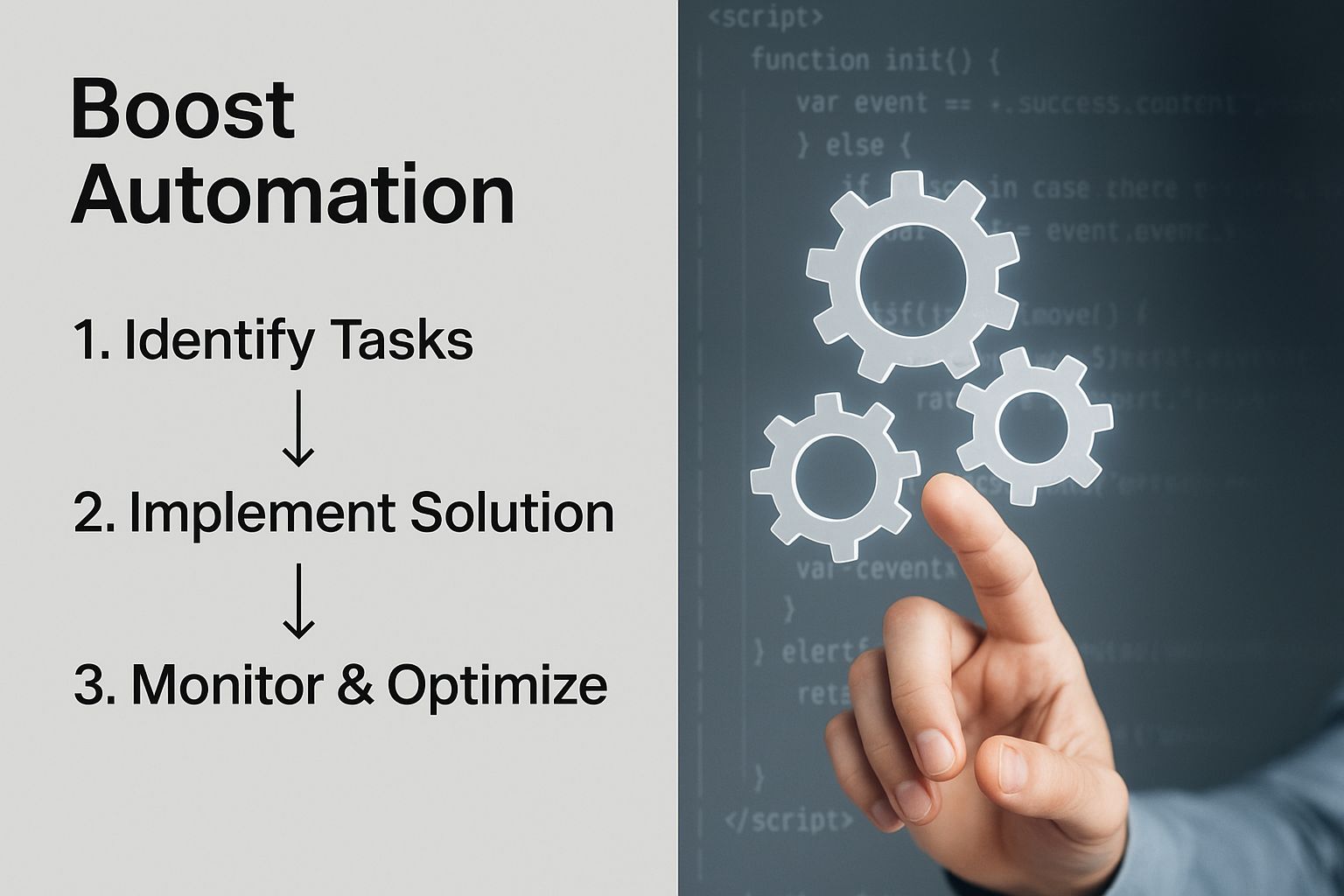

The most successful automation projects I’ve seen all started small. Don't try to automate your entire operation in one go. You'll burn out.

Instead, pick one or two of the most annoying, time-sucking tasks from your audit and automate those first. This approach is powerful. For a look at how this plays out in the real world, check out these practical business process automation examples.

Starting with a small, visible win proves the value of automation almost immediately, which is crucial for getting your team on board. Once they see how a simple automation saves them an hour every single day, they'll become your biggest advocates for finding the next opportunity. For a deeper dive, our guide on https://www.flowgenius.ai/post/how-to-automate-repetitive-tasks-and-boost-productivity is a great next step.

This momentum is more important than ever. The business world is fully embracing this shift. In 2025, global spending on generative AI is forecast to hit an astounding $644 billion—that's a 76.4% increase from the year before. And it’s not just talk; 78% of business leaders confirm their companies are already using AI in at least one area, from customer support to financial planning.

These numbers aren't just trivia. They show that getting smart about automation isn't just about being more efficient anymore. It’s about staying in the game.

How People and Processes Work Together

Great tools are a good starting point, but they're only one piece of the puzzle. The real magic happens when you dial in the connection between your people and your processes. Even the most sophisticated automation setup will fall flat if your team's communication is a mess. We need to focus on the human side of the equation—how people collaborate, make decisions, and interact every day.

True efficiency isn't about fancy software; it's about removing the friction in how your team works together. Think about it: endless email chains, constant status update meetings, and waiting forever on simple approvals are all signs of a broken process, not lazy people. By setting up clear, simple protocols, you give your team the guardrails they need to do their best work.

Stop the Distractions and Let People Focus

Nothing kills productivity faster than constant interruptions. The average person gets pulled off-task every few minutes, and it takes over 20 minutes to get back into a deep state of focus. This is where clear communication guidelines can be a game-changer.

First things first: get status updates out of everyone's inbox and out of the meeting room. A project management tool—whether it's Trello, Asana, or Jira—should be your single source of truth. When the entire team knows exactly where to find the latest updates, those "just checking in" emails and meetings simply disappear.

This small change naturally encourages asynchronous communication. It's not about banning real-time chats. It's about respecting each other's time by making async the default. A detailed comment on a project card is often far more effective (and less disruptive) than a tap on the shoulder.

Give Your Team the Authority to Act

One of the biggest bottlenecks I see in businesses is the approval queue. When a few key managers have to sign off on every little thing, work grinds to a halt. The simplest way to pick up the pace is to empower your team to make decisions within their defined roles.

Of course, this requires trust and clear boundaries. You need to define the scope of their decision-making power. For instance, a customer support rep could be authorized to issue refunds up to $100 without needing a manager's approval. This not only resolves customer issues in minutes instead of days but also boosts employee morale and makes them feel trusted.

Empowered teams don't just work faster; they work smarter. When people closest to the work have the authority to act, they spot opportunities and solve problems long before they ever escalate to management.

This kind of cultural shift changes your team from people who just do tasks to people who actively drive the company's success. It builds a proactive culture where everyone is looking for ways to improve things.

Make "Getting Better" Everyone's Job

The most efficient companies I've worked with treat optimization as a team sport. Your people on the front lines see the clunky workarounds and frustrating extra steps that leadership often misses. You absolutely need a simple, formal way for them to share their ideas.

This could be a dedicated Slack channel, an easy-to-use suggestion form, or even a standing agenda item in your weekly team meeting. The most important part is making it obvious that every idea is welcome and will be taken seriously. When you act on a suggestion and give public credit to the person who brought it up, you create a powerful feedback loop that encourages more great ideas.

This way, everyone starts thinking like an owner, constantly asking, "Is there a better way to do this?" For a deeper dive into refining these internal systems, check out our guide on how to streamline business processes for better efficiency today. By building these systems for clear communication and real empowerment, you create an organization that doesn’t just run well—it’s always getting better.

Weaving Sustainability into Your Business for Lasting Gains

When we talk about making a business more efficient, our minds usually jump to tech and workflows. But there’s a powerful, often missed, strategy right in front of us: sustainability. This is about more than just good PR or a corporate responsibility checkbox. Integrating Environmental, Social, and Governance (ESG) principles into how you operate is a direct line to smarter resource management and serious cost savings.

Thinking sustainably forces you to take a hard look at every nook and cranny of your business, from the materials you source to how you get your product into a customer's hands. This perspective naturally shines a light on waste you’d otherwise never see. It’s an investment that builds a tougher, more profitable company that's built to last.

Finding Profit in Greener Practices

The link between sustainability and efficiency really clicks when you look at real-world examples. Take packaging. Switching to a more compact, eco-friendly design does more than just win over green-minded customers; it directly slashes your material costs.

Lighter, smaller packages also mean cheaper shipping, which can be a massive budget-eater. Those savings drop right to your bottom line, and you lower your carbon footprint at the same time. It’s a classic win-win.

The same logic applies to investing in energy-efficient equipment. Sure, the upfront cost might be higher, but the long-term rewards are huge. Think about swapping out old office lights for LEDs or upgrading a clunky, energy-guzzling machine. You’ll see a dramatic drop in your utility bills month after month, giving you a reliable and predictable return on that initial spend.

The Power of the Circular Economy

One of the most profound ways to blend sustainability with efficiency is to embrace a circular economy model. This framework is a complete departure from the old "take-make-dispose" linear system. Instead, the whole point is to keep resources in play for as long as humanly possible.

This isn't some pie-in-the-sky idea; it's a practical business strategy that gets results. In fact, by 2025, top-tier companies are making ESG a core part of their operations to become more efficient and resilient. This often means adopting circular models that design waste out of the system from the start, which improves cost efficiency while shrinking their environmental impact. You can explore more insights on these trends and how they're shaping the future of business.

By completely rethinking your product's lifecycle, you can discover revenue streams that were literally hiding in your waste pile. What used to be a cost center can suddenly become a profit center.

This is a fundamental mindset shift. It’s about seeing value where everyone else just sees garbage and rethinking your entire relationship with your products and your customers.

Turning Waste into a Fresh Opportunity

So, what does this actually look like on the ground? Big retailers are showing us the way. Brands like Patagonia and Levi’s have seen incredible success by launching repair services and buy-back programs.

These programs are brilliant for a few key reasons:

Slash Raw Material Costs: When you refurbish and resell used products, you don't need to buy as many new—and often expensive—raw materials.

Create New Revenue Streams: The market for high-quality, pre-owned goods is exploding. Selling refurbished items opens up a whole new channel for income.

Boost Your Brand's Reputation: Today’s customers are fiercely loyal to brands that walk the talk on sustainability. These programs build that trust and attract a dedicated community.

Build Stronger Customer Bonds: Offering repair services keeps you connected to your customers long after they’ve made a purchase, which encourages loyalty and repeat business.

By building a closed-loop system, you're not just being a good corporate citizen. You're building a smarter, more efficient, and ultimately more profitable business from the inside out. It's definitive proof that doing good for the planet and doing well in business aren't competing goals—they're two sides of the very same coin.

How to Actually Measure the Impact of Your Efficiency Efforts

It feels great to roll out a new tool or tweak a clunky process. But until you have the data to back it up, those changes are just educated guesses. The old business adage, "If you can't measure it, you can't manage it," is spot on. To genuinely improve how your business runs, you have to move beyond gut feelings and start tracking the real-world results of your work.

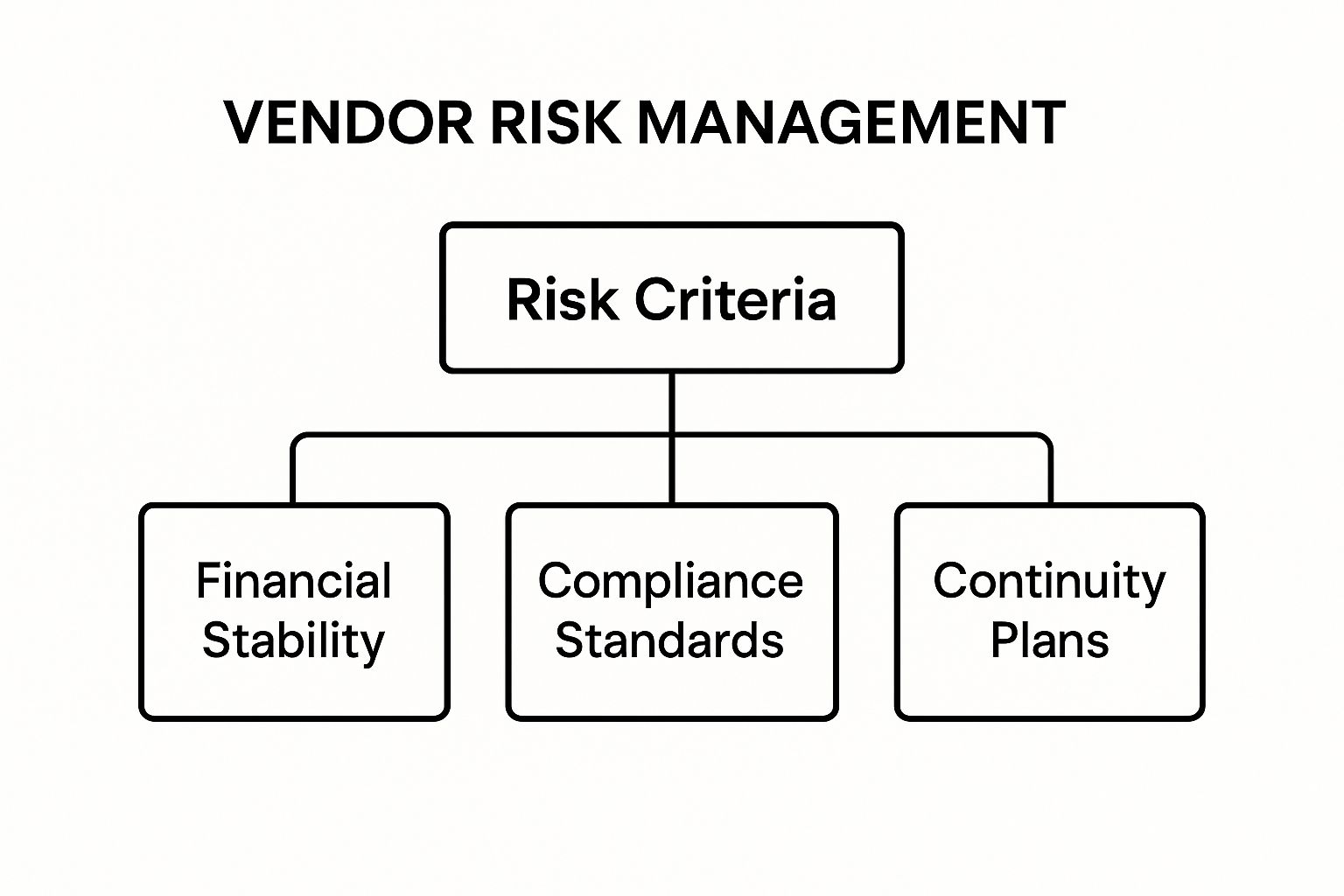

This is where you connect your efforts directly to the bottom line. It’s how you prove the ROI of that new software subscription or justify the time spent remapping a workflow. By setting up clear metrics from the get-go, you create a powerful feedback loop that fuels continuous, data-driven improvement rather than just a series of one-off fixes.

First Things First: Establish Your Baseline

The single biggest mistake I see people make is jumping straight into a solution without first measuring the problem. Before you automate a single task or change one step in a process, you must create a baseline. Think of it as your "before" picture—the benchmark against which all your future progress will be measured.

Without this starting point, you’re just guessing. A baseline gives you the concrete evidence needed to say, "This change saved us 40 hours per month," instead of just, "I think things are running faster now."

To set a solid baseline, pick a few key performance indicators (KPIs) that directly relate to the pain point you’re trying to solve.

Slow sales process? Measure the average cycle time from when a new lead hits your CRM to when the deal is officially closed.

Overloaded support team? Track the number of tickets an agent can resolve per day or the average time to first response.

Clunky content pipeline? Count the number of revision rounds a blog post goes through or the total time from the first draft to publication.

These aren't vanity metrics. They're direct measurements of the friction you found during your audit.

Go Beyond Simple Numbers to Find Meaningful KPIs

Once your new process is live, the goal is to keep tracking those same KPIs. But it’s crucial to pick metrics that truly reflect efficiency, not just activity. For instance, tracking the number of emails your team sends is pretty useless. Tracking a drop in the number of emails needed to resolve a customer issue? Now that's valuable.

Here are a few powerful KPIs that get right to the heart of operational efficiency:

Cost Per Transaction/Action: Figure out how much it costs to complete a key action, like processing an invoice or onboarding a new client. As you introduce automation and streamline workflows, this number should go down.

Output Per Employee: A classic for a reason. Whether it’s sales calls made, products assembled, or articles written, tracking output helps you quantify real productivity gains.

Error Rate Reduction: Automation is brilliant at cutting down on human error. Track the percentage of orders with mistakes or invoices that need correction before and after your changes to see a direct lift in quality.

True efficiency isn't just about doing more work in less time. It's about achieving better outcomes—fewer errors, lower costs, and happier customers—with the same or fewer resources.

This mindset helps you focus on what really matters. A 15% reduction in your cost per transaction is a much more compelling story for your leadership team than simply saying you bought new software.

Don't Forget the Human Element: Qualitative Feedback

Data tells you what happened. Your team can tell you why. Numbers alone can't capture the whole story. Did automating that tedious report free up a team member to build a better relationship with a key client? Did the new project management system reduce stress and finally put an end to late-night work sessions?

This kind of qualitative feedback is gold. It reveals the human impact of your efforts, which is often just as important as the financial ROI.

Gathering this feedback doesn't have to be complicated.

Quick Surveys: Use a simple tool like Google Forms to send out a short, anonymous survey asking the team how the new process feels.

One-on-One Check-ins: Just casually ask team members during your regular meetings what they think of the new workflow.

Team Retrospectives: Set aside 15 minutes in a team meeting to discuss what’s working well with the new system and what could still be tweaked.

When you combine hard data with human stories, you build an undeniable case for the value of your work. You prove that you’re not just making the business more efficient—you’re making it a better place to work.

Answering Your Top Questions About Business Efficiency

When you start digging into making your business run smoother, a lot of questions pop up. It's a common journey. Here are some straightforward answers to the questions I hear most often from leaders ready to boost efficiency and grow their business.

Where Do I Even Start?

The single best place to begin is with a workflow audit. Don't just guess where the snags are. You need to get a clear picture of a critical process from the very first step to the last.

Actually mapping it out—on a whiteboard, with sticky notes, whatever works—is a game-changer. It shines a light on all the hidden bottlenecks, duplicated efforts, and annoying delays that are costing you time and money.

And here's the most important part: get the people who do the work involved. Your team on the front lines knows exactly where the friction is. Their insights are pure gold and will turn a simple mapping exercise into a real plan for improvement.

How Do I Know if It’s Actually Working?

You measure it. But you have to measure the right things. Forget vanity metrics and focus on the key performance indicators (KPIs) that show real progress toward your goals.

I've found these are some of the most telling metrics:

Cycle Time: How long does it take to get one thing done, from start to finish? Shorter is always better.

Output Per Employee: A classic for a reason. Are you producing more units or closing more support tickets with the same team? That's a clear win.

Cost Per Acquisition: This tells you if your marketing and sales engine is becoming more efficient at bringing in new customers.

Error Rates: Faster is great, but faster with fewer mistakes is even better. A drop in errors means your process is more reliable.

The trick is to get your baseline numbers before you change anything. That way, you can clearly see the impact of your work and prove that these efficiency projects are paying off.

Is Automation Really for Small Businesses?

100% yes. I'd argue small businesses often get the biggest bang for their buck with automation. When you're a small team, every single hour you save has a massive impact on your bottom line and your ability to focus on what matters.

Modern no-code tools are the great equalizer. They give small businesses the kind of operational power that used to be reserved for giant corporations with big IT teams.

Tools like Zapier or Make let you connect the apps you already use every day, like QuickBooks and Gmail. Imagine automatically sending follow-up emails, creating invoice reminders, or moving data between spreadsheets without lifting a finger. You don't need a developer; you just need a plan. This frees up your team to do the creative, strategic work that actually grows the company.

Ready to stop wasting time on manual tasks and start building a more efficient business? Flow Genius specializes in creating and implementing the exact automation systems you need to eliminate bottlenecks and scale effectively. Schedule your free consultation today and discover how much time you could be saving.